Soarer 2JZGTE VVTi Conversion

I generally don't get sentimental about cars.. But I'm pretty fond of this one..

The story starts about 4yrs ago when I bought my first ever Soarer, loved it to bits.. Reluctantly sold it to the chic I was seeing at the time.. She did a W58 Manual conversion on it, Coilovers, and a few other bits on it and enjoyed drifting it for 3 years.. It was then reshelled into the current Soarer which has been good as gold for the past year..

Few weeks ago it started showing signs of a dying turbo.. Last weekend I changed the turbos.. However, on the way to my workshop it spat a load of turbo blade through the engine, compression was down to 95psi on 2cylinders and rattling it's tits off..

We took the turbos off and spent a lot of time trying to get the crap out the engine, stuck a Bore Scope down to see what was going on, made attachments to Hoover the bits out of the cylinders, etc.. But we couldn't get the bits that were already mashed into the valve seats.. So we had 2 options.. Either strip it down and fix it, or stick the new turbos on and give it some beans and see if it spits it back out.. It didn't get better..

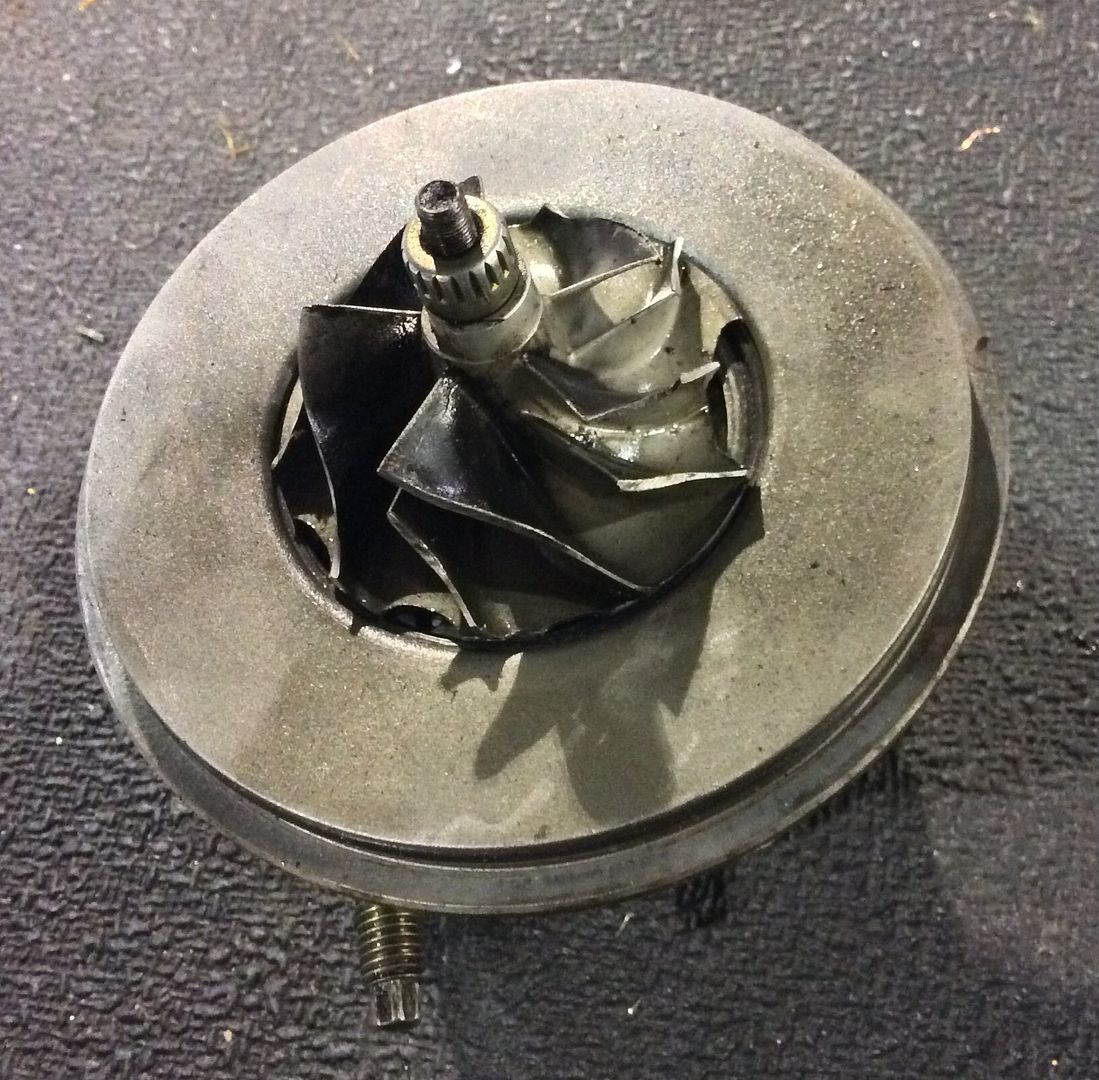

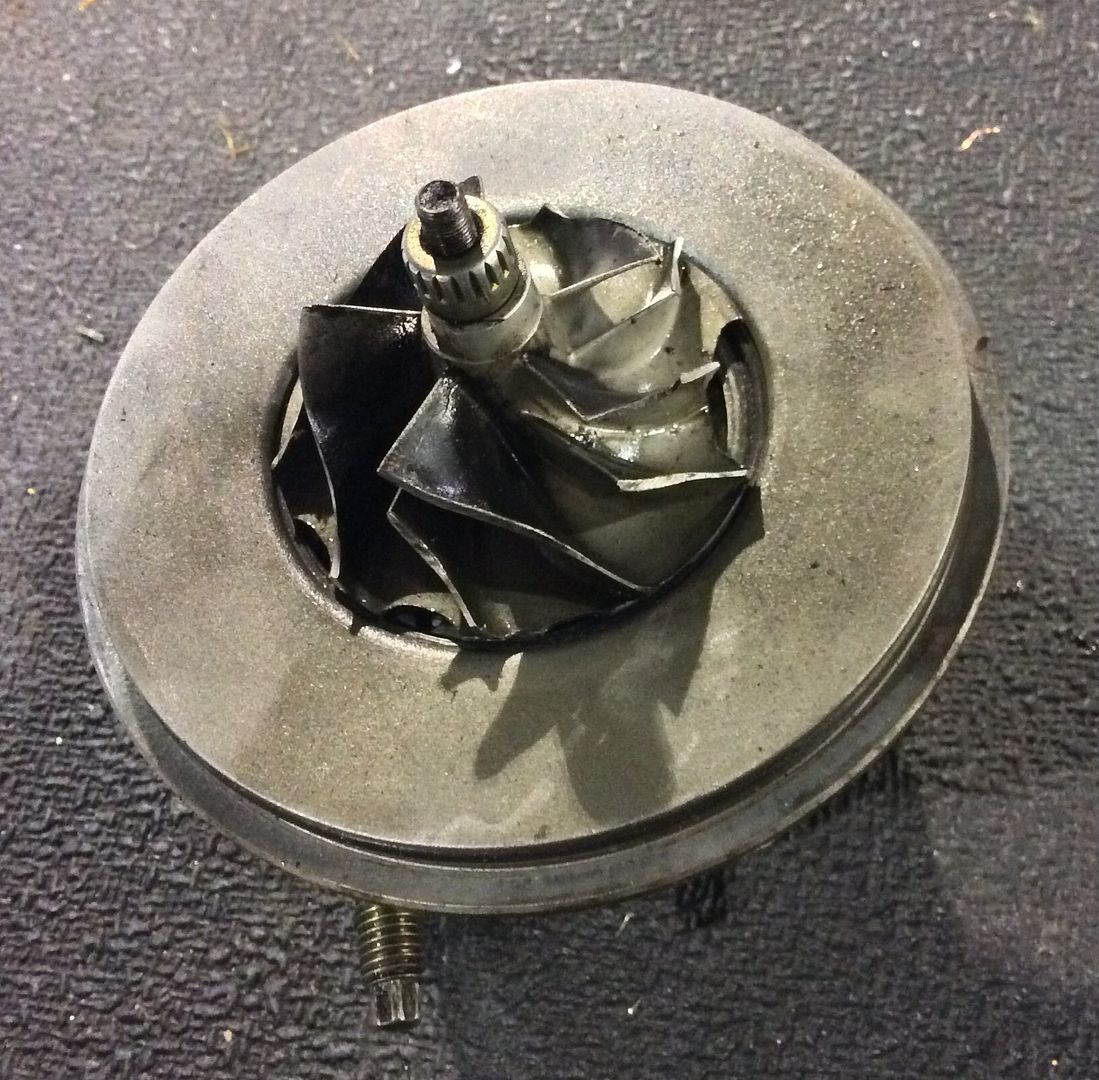

This is the turbo.. Those missing bits must have wiggled there way through the Intercooler and into the engine.. The shaft is also snapped and bearing disintegrated.. Bits of metal gone through the oil galleries in the turbo and into the engine..

So she somehow managed to blag her brother and got 2jzgte vvti he'd just removed from an Aristo for a project he wants to do sometime in the future..

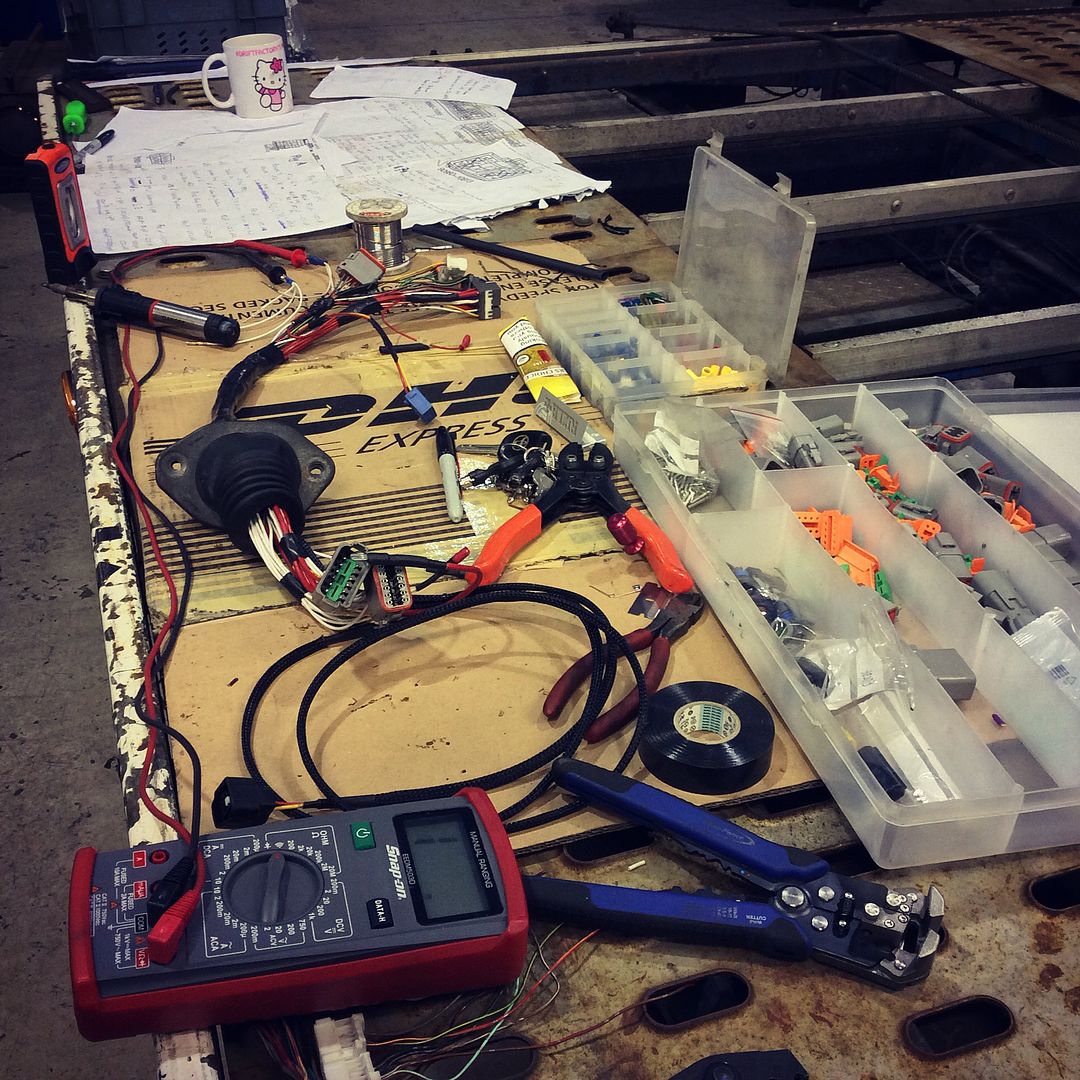

We got the car in and started work..

The engine bay was discussing.. Used 10L of brake cleaner to get all the leaked oil off..

Before:

After:

I went and picked the engine up, handful of bits are missing but luckily the car hasn't gone to scrap yet so I'll go get the rest of the bits I need to make this a decent quality conversion..

The engine is going in as standard and keeping with the standard Auto gearbox..

It's got 98k Kms so 60k Miles.. I'd advise a cambelt change, water pump, etc, but there isn't the budget to do it..

We've changed the from the front sump to a Soarer mid sump.. This involves changing the turbo Oil return fitting too, which means changing the pipework to fit onto the Y piece. The original rubber pipes are moulded pipes, they're always brittle and split/snap.. It's a 22mm pipe, when using silicon(this is Fluro lined oil grade silicon pipe) it won't achieve the radius and it'll kink, so I removed the metal pipe and Tig welded a new bend on so we just have a short silicon joiner..

The AirCon has also been deleted, I'm sure I could have made it work, but there's a lot of wiring involved and I'm not sure how compatible the 2 systems would be and there's not enough budget to look into it..

So the AC pump has bee removed, and a special bracket made to support the PAS pump.. Iv spun the Oil Filter Housing round to make oil changes easier and less messy.. Fitted new pipework to the water/oil heat exchange in the housing..

The original engine mounts are completely shagged, they must have been 2 bits for quite some time judging by the state of them..

Because of the tight budget I knocked up some hockey puck mounts as a temporary measure. There's 3 stacked in the pic, I cut on in half so it was only 2.5 pucks thick, sits the engine in exactly as per factory.. I despise these hockey puck mounts but needs must.. Will be replaced asap with proper StrongFlex mounts..

Engine went in pretty easy, we used the Soarer engine brackets and Soarer Auto trans mount, bolted straight up.

We've used several bits from the Soarer and Aristo to make everything work, the PAS Pump is Soarer so the lines bolt up, the original Proportional Power Steering sensor in the steering rack has been wired back to the distribution board as per OEM wiring, same goes for the Heater Matrix Valve on the bulk head..

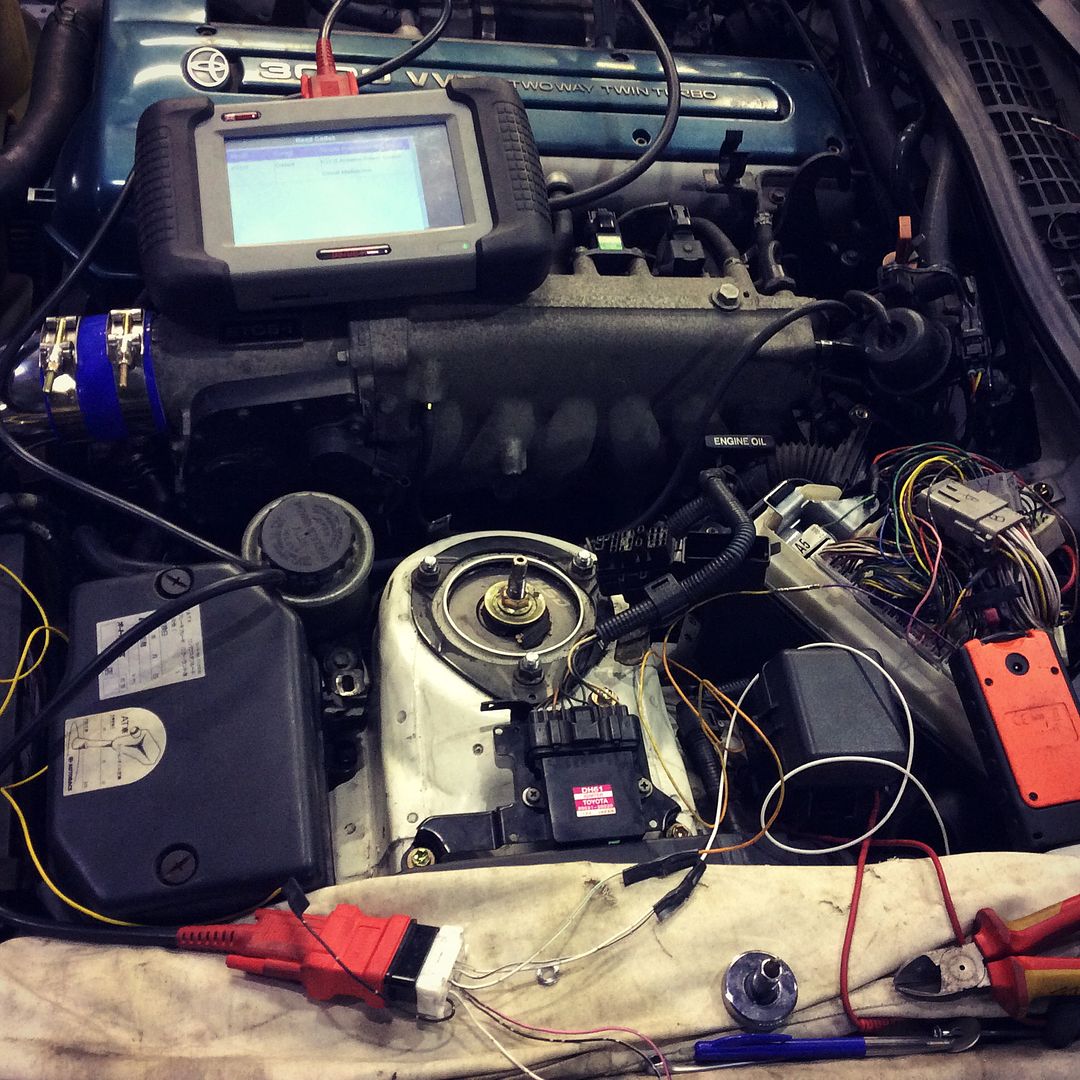

Fitted the original Aristo ECU box into the Soarer bay, this wasn't easy, wasted hours pissing around with different placements, and then making intricate brackets to support it.. I like where it is because the wiring is short piece of loom to connect up in the passenger footwell..

I generally don't get sentimental about cars.. But I'm pretty fond of this one..

The story starts about 4yrs ago when I bought my first ever Soarer, loved it to bits.. Reluctantly sold it to the chic I was seeing at the time.. She did a W58 Manual conversion on it, Coilovers, and a few other bits on it and enjoyed drifting it for 3 years.. It was then reshelled into the current Soarer which has been good as gold for the past year..

Few weeks ago it started showing signs of a dying turbo.. Last weekend I changed the turbos.. However, on the way to my workshop it spat a load of turbo blade through the engine, compression was down to 95psi on 2cylinders and rattling it's tits off..

We took the turbos off and spent a lot of time trying to get the crap out the engine, stuck a Bore Scope down to see what was going on, made attachments to Hoover the bits out of the cylinders, etc.. But we couldn't get the bits that were already mashed into the valve seats.. So we had 2 options.. Either strip it down and fix it, or stick the new turbos on and give it some beans and see if it spits it back out.. It didn't get better..

This is the turbo.. Those missing bits must have wiggled there way through the Intercooler and into the engine.. The shaft is also snapped and bearing disintegrated.. Bits of metal gone through the oil galleries in the turbo and into the engine..

So she somehow managed to blag her brother and got 2jzgte vvti he'd just removed from an Aristo for a project he wants to do sometime in the future..

We got the car in and started work..

The engine bay was discussing.. Used 10L of brake cleaner to get all the leaked oil off..

Before:

After:

I went and picked the engine up, handful of bits are missing but luckily the car hasn't gone to scrap yet so I'll go get the rest of the bits I need to make this a decent quality conversion..

The engine is going in as standard and keeping with the standard Auto gearbox..

It's got 98k Kms so 60k Miles.. I'd advise a cambelt change, water pump, etc, but there isn't the budget to do it..

We've changed the from the front sump to a Soarer mid sump.. This involves changing the turbo Oil return fitting too, which means changing the pipework to fit onto the Y piece. The original rubber pipes are moulded pipes, they're always brittle and split/snap.. It's a 22mm pipe, when using silicon(this is Fluro lined oil grade silicon pipe) it won't achieve the radius and it'll kink, so I removed the metal pipe and Tig welded a new bend on so we just have a short silicon joiner..

The AirCon has also been deleted, I'm sure I could have made it work, but there's a lot of wiring involved and I'm not sure how compatible the 2 systems would be and there's not enough budget to look into it..

So the AC pump has bee removed, and a special bracket made to support the PAS pump.. Iv spun the Oil Filter Housing round to make oil changes easier and less messy.. Fitted new pipework to the water/oil heat exchange in the housing..

The original engine mounts are completely shagged, they must have been 2 bits for quite some time judging by the state of them..

Because of the tight budget I knocked up some hockey puck mounts as a temporary measure. There's 3 stacked in the pic, I cut on in half so it was only 2.5 pucks thick, sits the engine in exactly as per factory.. I despise these hockey puck mounts but needs must.. Will be replaced asap with proper StrongFlex mounts..

Engine went in pretty easy, we used the Soarer engine brackets and Soarer Auto trans mount, bolted straight up.

We've used several bits from the Soarer and Aristo to make everything work, the PAS Pump is Soarer so the lines bolt up, the original Proportional Power Steering sensor in the steering rack has been wired back to the distribution board as per OEM wiring, same goes for the Heater Matrix Valve on the bulk head..

Fitted the original Aristo ECU box into the Soarer bay, this wasn't easy, wasted hours pissing around with different placements, and then making intricate brackets to support it.. I like where it is because the wiring is short piece of loom to connect up in the passenger footwell..

Last edited: