You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pic of the day thread (no picture, no post!!)

- Thread starter BanjoMaster

- Start date

Stavros

Active Member

All Formula Atlantic blocks I've seen have had the lugs machined off the back of the block (gearbox end) as they won't fit in to the single seaters they are meant to be mounted to if they have that all on it.

Like this

In fact all the Formula Atlantic engines I've seen fitted to AE86s etc in the past are the entire engine (ie all the front cover stuff, internals, fancy cam cover, etc etc) but using a non-original FA block as the FA block can't be fitted to an 86 anymore due to the mounts etc machined off.

Like this

In fact all the Formula Atlantic engines I've seen fitted to AE86s etc in the past are the entire engine (ie all the front cover stuff, internals, fancy cam cover, etc etc) but using a non-original FA block as the FA block can't be fitted to an 86 anymore due to the mounts etc machined off.

Last edited:

BillyEdmonds

New Member

All Formula Atlantic blocks I've seen have had the lugs machined off the back of the block (gearbox end) as they won't fit in to the single seaters they are meant to be mounted to if they have that all on it.

Like this

In fact all the Formula Atlantic engines I've seen fitted to AE86s etc in the past are the entire engine (ie all the front cover stuff, internals, fancy cam cover, etc etc) but using a non-original FA block as the FA block can't be fitted to an 86 anymore due to the mounts etc machined off.

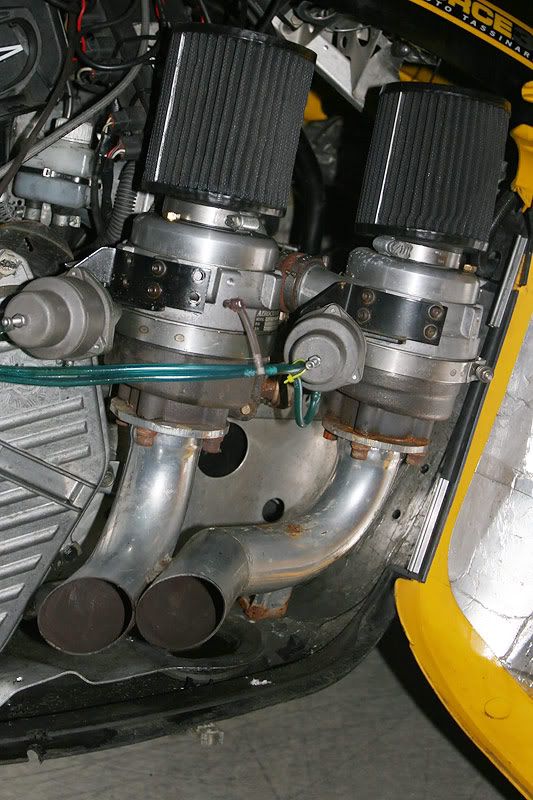

At the risk of turning a picture thread into a discussion thread, you are correct, many engine blocks have had the lower mounting holes removed ( commonly referred to as “ears” ). The ears were removed only for certain chassis’ such as Swift 008 & Swift 014 as well as a few others. In fact, it’s technically more desirable to have an engine with the ears because when the time comes to sell you can appeal to all buyers & not just the ones who have a specific chassis with specific requirements. The blocks are basically disposable, meaning after a certain amount of time they will have become stressed, cracked or the bores cannot no longer be kept in the 1600cc range for the specific class. Because of this the 4age you might see in a Corolla at Tesco could very well be a series winning engine next year. The oil system is machined & changed to work correctly with the dry sump set up, the inside of the block adjacent to the main caps is recessed to allow for straps to be bolted across the caps & into the inside of the block. Approx. 40 hours of machining goes into the preparation of each standard block. Below are pictures of some engines, one with a billet transmission adapter & a couple with the ears still in place.

I regularly buy standard engines that are doing 11,500rpm 6 months later in someone’s car…..

burgerboy78

SCHWING

burgerboy78

SCHWING

Mcfrickinbenj

New Member

haha gangster!!!