prblmslvrs

Active Member

So after fucking the Mx5's chassis from running low I decided to sell it to someone that could be arsed with repairing it.

Was looking for a Nissan, R32 or S13/S14's to replace it as my daily drifter. I know that i'm not going to get near the reliability and seat time that I had with the Mx5 but I just wanted a change and wanted a car I actually gave a fuck about what it looked like.

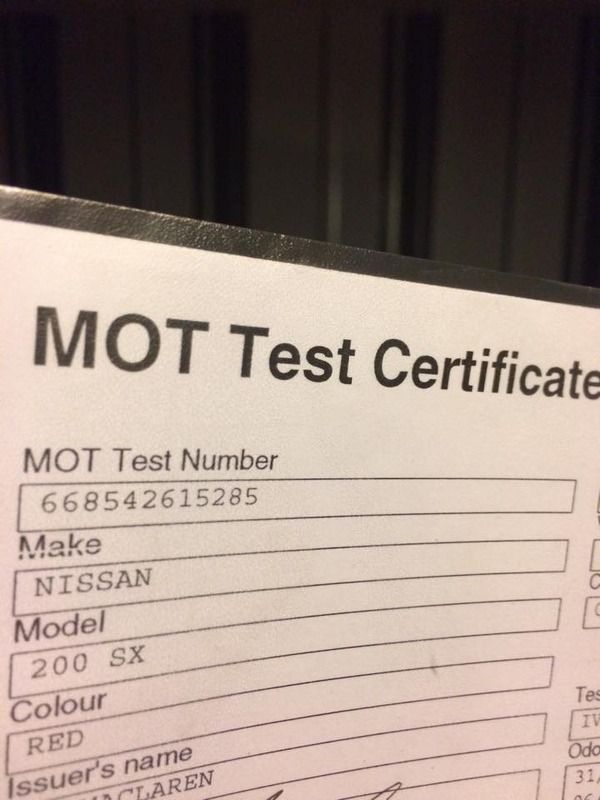

Was about to buy flights to do a 400 mile round trip for an MOT'ed S13 when I was told about one only 40 miles away but needed work.

Price was at the top of my budget which i was a bit put off for as I'd never pay over £1k for a car with no MOT, never mind a crusty Nissan for £2k! Went to see it and the car was bloody well specced, just a bit crusty. Since I can't weld I sent pics to my mate who does body work for Rally cars and he said he will take it on for me.

Its a 92 with a rebuilt CA18DET, T28r running stage 3. Apex Coilovers, R33 GTST brakes all round. Adjustable arms where they're needed and just about anything I was planning to do already done.

Got it home and with me being the impatient bastard I am I cracked it up in the air and got to work with finding all the crusty bits with a wire wheel/knotted wheel

This was quite worrying at the seatbelt mount.

Decided to start cutting to see how bad the repairs would be.

Discovered there was fuck all left of the inner chassis rail. Patching it up wouldn't do whole new inner sill etc it is.

Decided fuck it, I'm going to borrow a MIG welder from a mate and get stuck in!

Done a few practice welds putting stuff together and after wasting bottle of gas on a fucked regulator I cut the whole inner sill and floor out and got to patching the bastard up.

My welding isn't fantastic but its penetrating through so thats the main thing.

Found this under a patch in the drivers footwell Glad i decided not to go down the "Bang it together for an MOT" route.

Glad i decided not to go down the "Bang it together for an MOT" route.

In between cursing at all the crust I did a couple jobs. Did a front bumper cut on the pignose.

and re-tucked the engine loom, already had been done before so was just a case of re-cable tieing.

Finally I was tracing back the OS sill crust a bit more and discovered its right through into the wheel arch/subframe mounting area. Definitely a job for someone thats not an amateur.

So much for leaving it for my mate to do all the work...

Was looking for a Nissan, R32 or S13/S14's to replace it as my daily drifter. I know that i'm not going to get near the reliability and seat time that I had with the Mx5 but I just wanted a change and wanted a car I actually gave a fuck about what it looked like.

Was about to buy flights to do a 400 mile round trip for an MOT'ed S13 when I was told about one only 40 miles away but needed work.

Price was at the top of my budget which i was a bit put off for as I'd never pay over £1k for a car with no MOT, never mind a crusty Nissan for £2k! Went to see it and the car was bloody well specced, just a bit crusty. Since I can't weld I sent pics to my mate who does body work for Rally cars and he said he will take it on for me.

Its a 92 with a rebuilt CA18DET, T28r running stage 3. Apex Coilovers, R33 GTST brakes all round. Adjustable arms where they're needed and just about anything I was planning to do already done.

Got it home and with me being the impatient bastard I am I cracked it up in the air and got to work with finding all the crusty bits with a wire wheel/knotted wheel

This was quite worrying at the seatbelt mount.

Decided to start cutting to see how bad the repairs would be.

Discovered there was fuck all left of the inner chassis rail. Patching it up wouldn't do whole new inner sill etc it is.

Decided fuck it, I'm going to borrow a MIG welder from a mate and get stuck in!

Done a few practice welds putting stuff together and after wasting bottle of gas on a fucked regulator I cut the whole inner sill and floor out and got to patching the bastard up.

My welding isn't fantastic but its penetrating through so thats the main thing.

Found this under a patch in the drivers footwell

Glad i decided not to go down the "Bang it together for an MOT" route.

Glad i decided not to go down the "Bang it together for an MOT" route.In between cursing at all the crust I did a couple jobs. Did a front bumper cut on the pignose.

and re-tucked the engine loom, already had been done before so was just a case of re-cable tieing.

Finally I was tracing back the OS sill crust a bit more and discovered its right through into the wheel arch/subframe mounting area. Definitely a job for someone thats not an amateur.

So much for leaving it for my mate to do all the work...