You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

sparky_s13

Active Member

Sick mate!

Should be at Matsuri so I'll be sure to come say Hi and take some pics

Should be at Matsuri so I'll be sure to come say Hi and take some pics

Domenik Ziiba

New Member

This Thing looks just stunning dude !!

200sx_

PS13 x TD Power

So what happened to this then?

I still have the car, mapping is booked for the 14th October - so if all goes well, i'll do a hugeeeee update and hope make Anglesey on the weekend just before my birthday which would be cool. But we'll cross that bridge if we get there

200sx_

PS13 x TD Power

How's this getting on?

Its doing good, there has been progress - i've just been too lazy to update this haha! Give me some time and i'll do a comprehensive update

200sx_

PS13 x TD Power

Jeeez, it’s been a while!

Quite a lot has happened since the last update, and those who keep up to date with my Instagram will have seen the car progress over the past few months. I guess general life has gotten in the way of things, and unintentionally taking a back seat from the scene (it’s gotten far too clique’y!).

So the first start up was a success, and the motor sounded insane! A little bit too loud, but the rasp was just perfect. There were no major leaks and it built oil pressure quickly.

But, it was a huge learning curve – it highlighted weaknesses that I must change. The first task I wanted to tackle was reassembling the interior. Even though this car will be dedicated for the track, I still want it to resemble the S13 chassis. I have had thoughts of an S15 dash conversion, but the S13 dash is pretty iconic in my opinion! Maybe an idea for the future though..

As I posted on the other page – I purchased a pair of Work Equip CR Kiwami’s. The obvious thing was to throw on a pair of 235/40’s and trial fit them. I could just about squeeze them under the front Origin +40mm fenders – the words “just” and “about” should be highlighted in bold!

Holy ****! They suit the car down to the ground – a D1 kind of vibe. In the quest to gain a little more clearance up front I set about reducing the track width of my PBM Front Lower Control Arms. I love how easy these things are to setup!

I do however want the front end to sit lower as it sits just that little bit too high in my honest opinion.

A pair of the WORK’s wasn’t too bad in terms of price – so I got another pair. But this time in 18x9.5 ET0 flavour so I could gain a bit of clearance and run a larger tire on the rear. A 9.5 wheel is pretty versatile, anything from a 215 – 265, all of which are ideal for this car depending on its use.

I love the vibe this car gives – something I never predicted would happen! It’s been a long time in the making, but the aura is just incredible. It has presence.

Quite a lot has happened since the last update, and those who keep up to date with my Instagram will have seen the car progress over the past few months. I guess general life has gotten in the way of things, and unintentionally taking a back seat from the scene (it’s gotten far too clique’y!).

So the first start up was a success, and the motor sounded insane! A little bit too loud, but the rasp was just perfect. There were no major leaks and it built oil pressure quickly.

But, it was a huge learning curve – it highlighted weaknesses that I must change. The first task I wanted to tackle was reassembling the interior. Even though this car will be dedicated for the track, I still want it to resemble the S13 chassis. I have had thoughts of an S15 dash conversion, but the S13 dash is pretty iconic in my opinion! Maybe an idea for the future though..

As I posted on the other page – I purchased a pair of Work Equip CR Kiwami’s. The obvious thing was to throw on a pair of 235/40’s and trial fit them. I could just about squeeze them under the front Origin +40mm fenders – the words “just” and “about” should be highlighted in bold!

Holy ****! They suit the car down to the ground – a D1 kind of vibe. In the quest to gain a little more clearance up front I set about reducing the track width of my PBM Front Lower Control Arms. I love how easy these things are to setup!

I do however want the front end to sit lower as it sits just that little bit too high in my honest opinion.

A pair of the WORK’s wasn’t too bad in terms of price – so I got another pair. But this time in 18x9.5 ET0 flavour so I could gain a bit of clearance and run a larger tire on the rear. A 9.5 wheel is pretty versatile, anything from a 215 – 265, all of which are ideal for this car depending on its use.

I love the vibe this car gives – something I never predicted would happen! It’s been a long time in the making, but the aura is just incredible. It has presence.

200sx_

PS13 x TD Power

Now it was time to turn back to the reassembly of the interior – first things first was my old Grip Royal steering wheel. I ran this in my old S13 – and plan to run it again in this chassis – albeit with its new bronze centre due to its age – but I dig it!

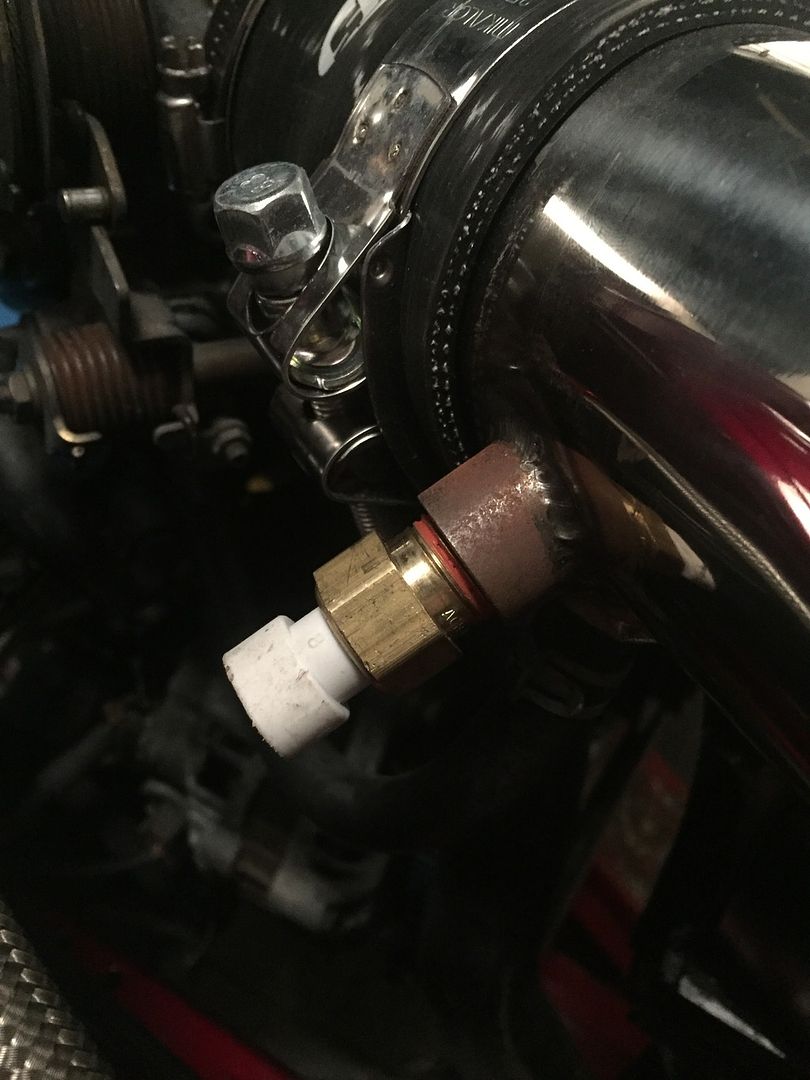

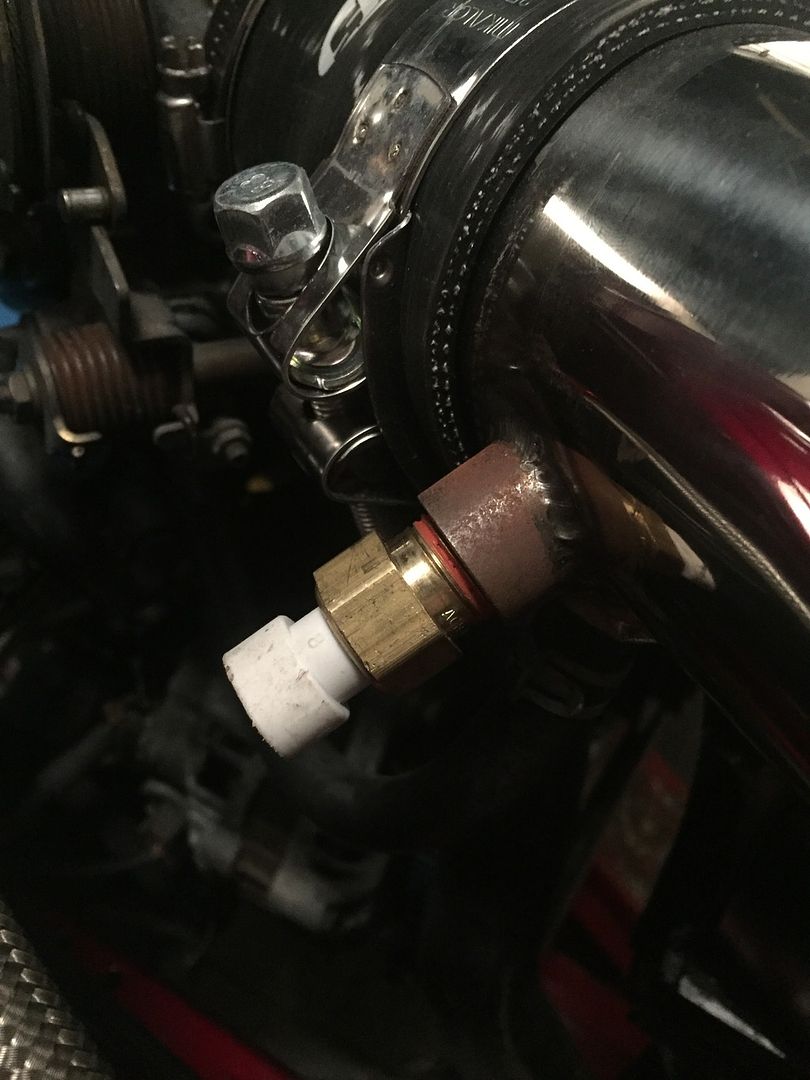

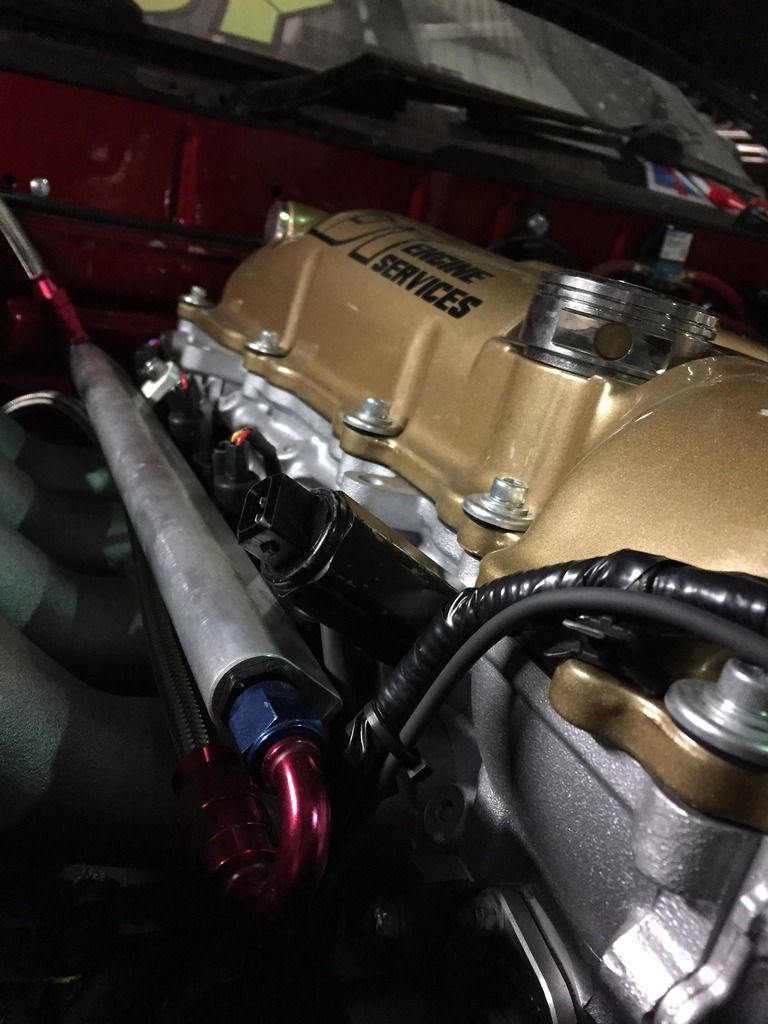

I think I touched on it previously – but upon plumbing up the fuel rail I made the stupid mistake of plumbing the FPR before the fuel rail, rather than after! Got to make mistakes to learn ehh..

So here was our “bodge” to get the motor running late at night:

So I started stripping the fuel rail down – as a small 1/8NPT bung was continually leaking.

I tried everything bar PTFE tape to get this bung to seal. The idea of a small bit of PTFE breaking free in the fuel rail and clogging a fuel injector wasn’t something I wanted to happen – I want to try and get everything setup perfectly now so things wont go wrong in the future * touch wood * so I’ll just get it TIG’d up!

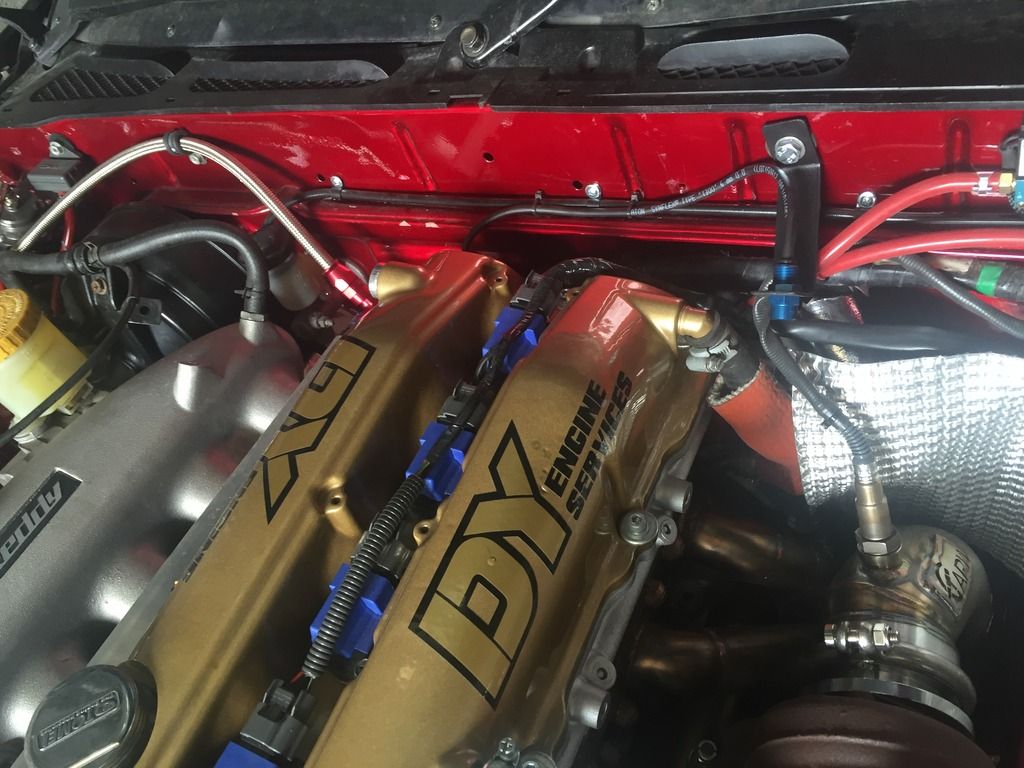

Whilst I was waiting for the local fabricator to free up some space to squeeze my fuel rail in, I ordered lots of vacuum hose in order to plumb everything up neatly.

(Red of course to match the bay!)

Whilst most people use cable ties or even nothing to hold their vac hoses onto the ports, this simply wouldn’t do for me Not to worry, a bunch of constant tension clamps will make sure they are constantly sealed and wont pop off!

Not to worry, a bunch of constant tension clamps will make sure they are constantly sealed and wont pop off!

- - - Updated - - -

As a result of plumbing up the FPR incorrectly – I spent another small fortune on AN/Dash fittings plus braided hose. Anyone whose bought these fitting and lines will understand the cost of them!

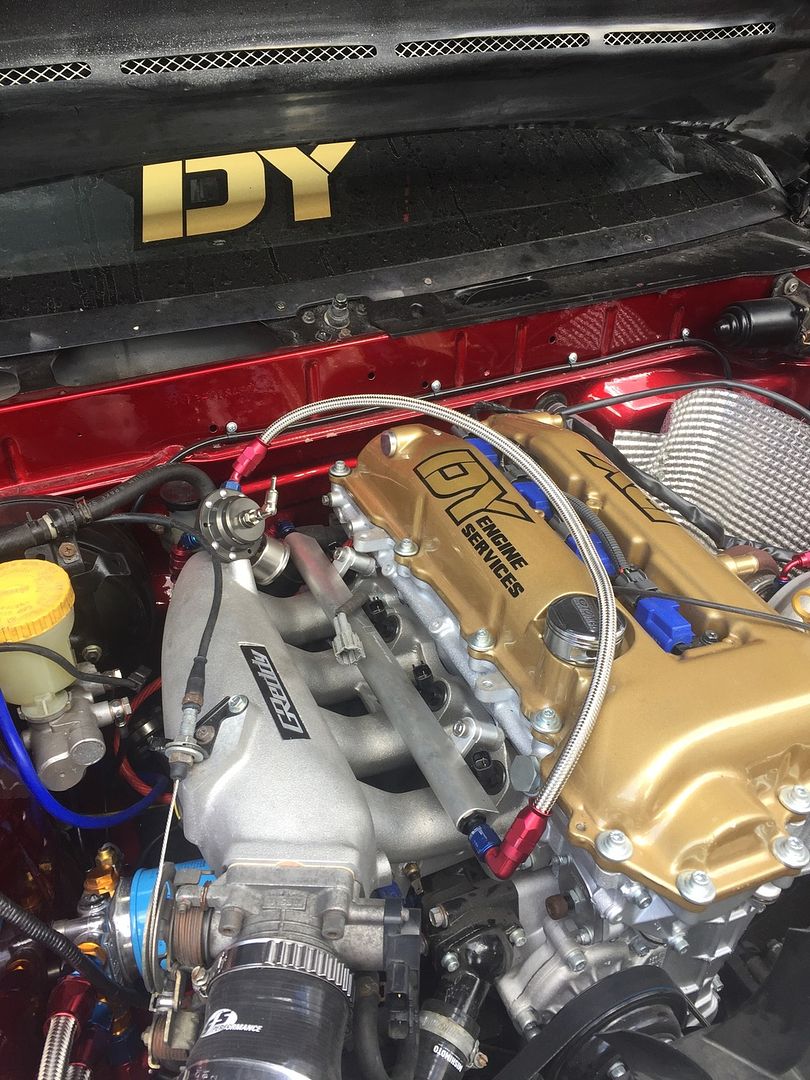

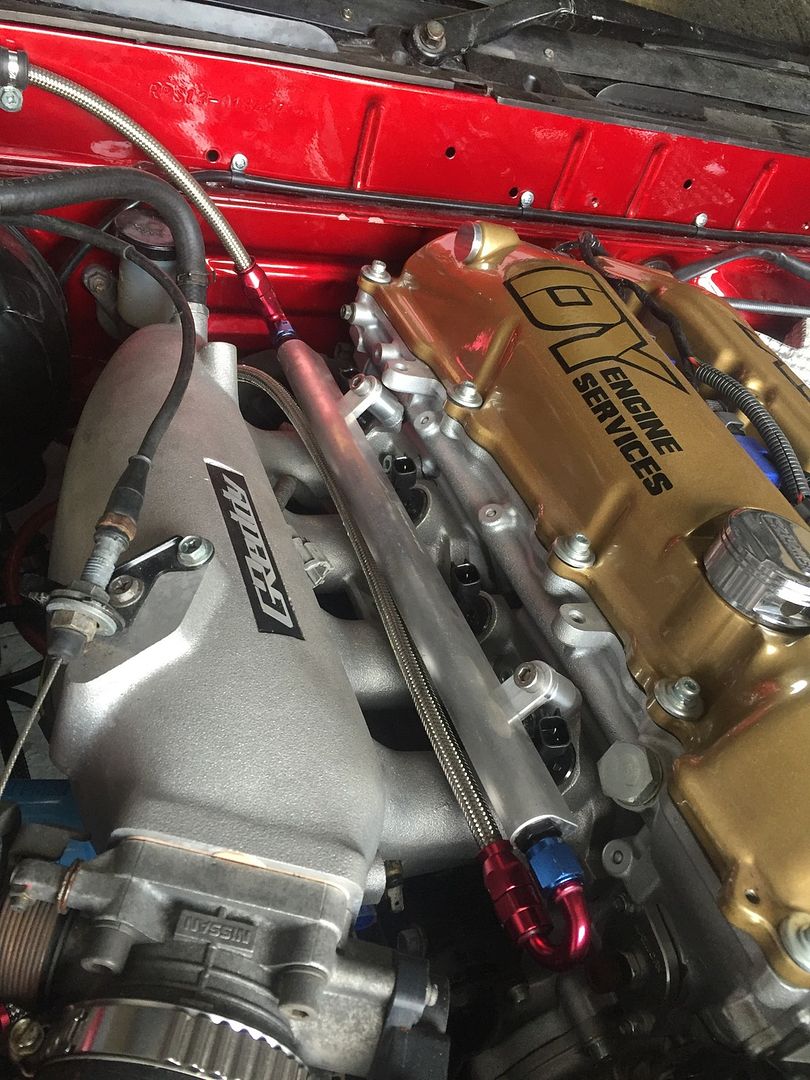

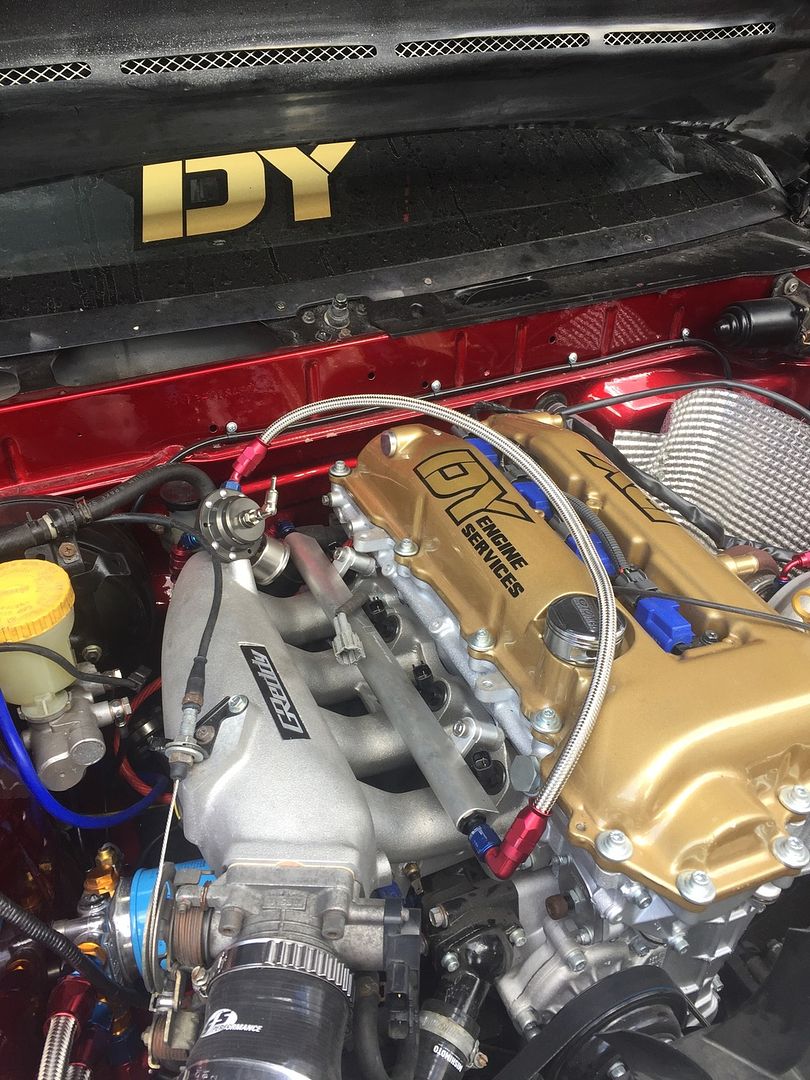

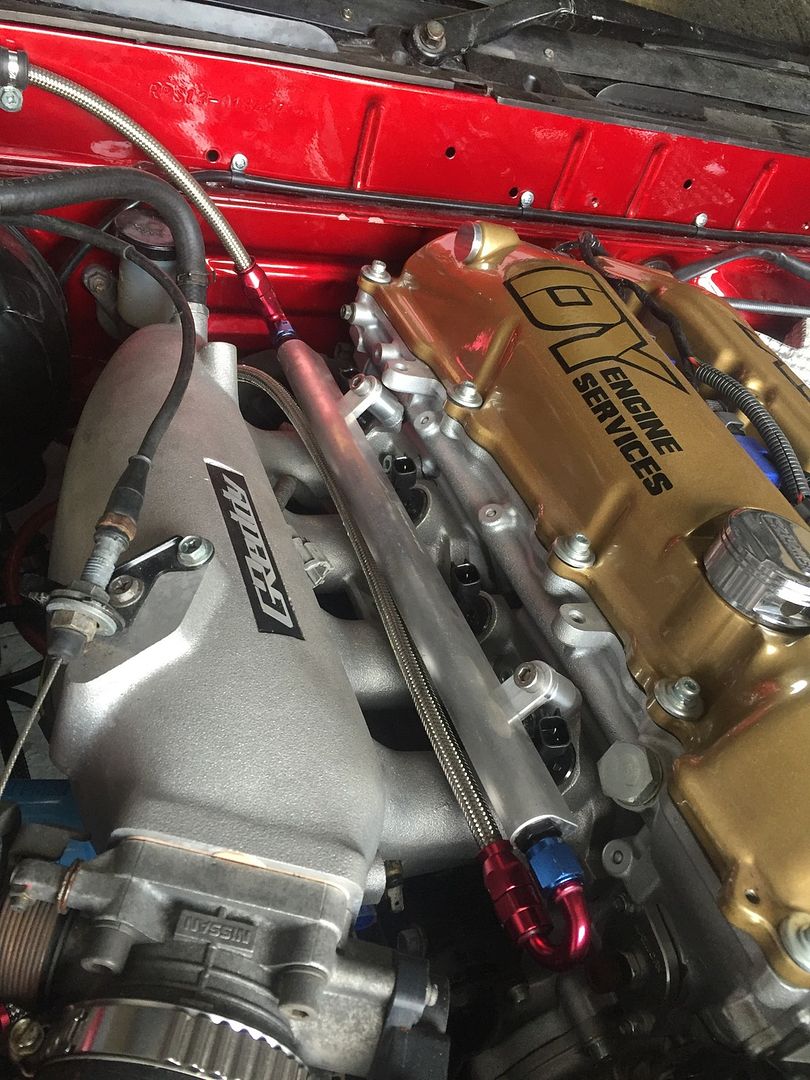

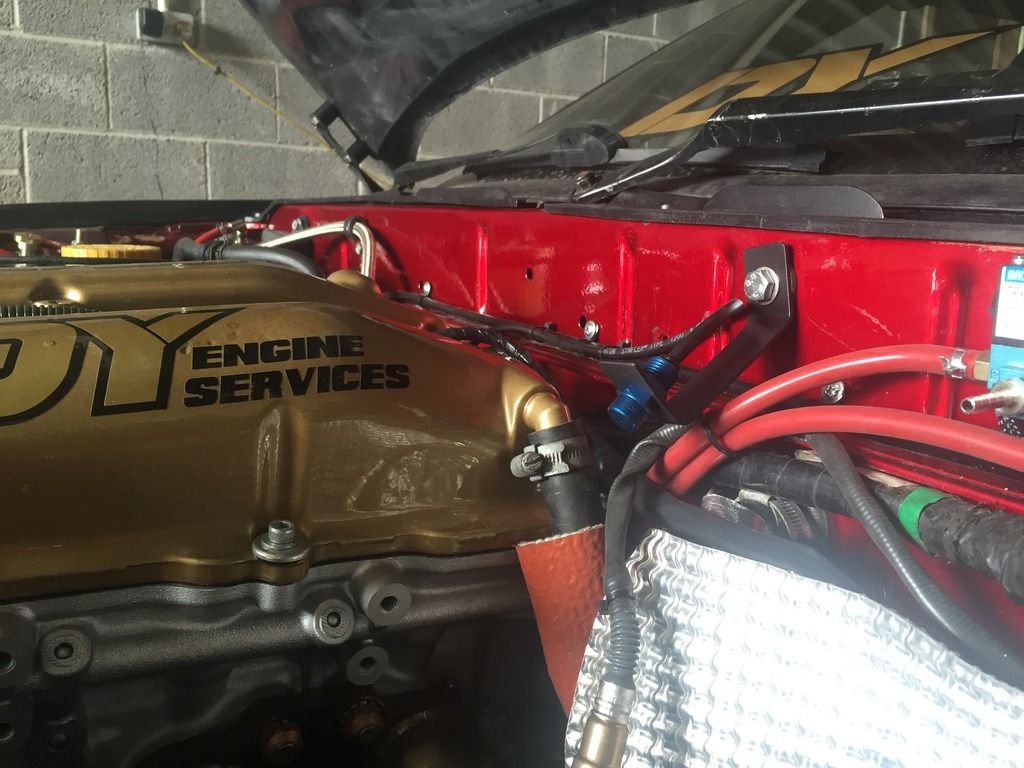

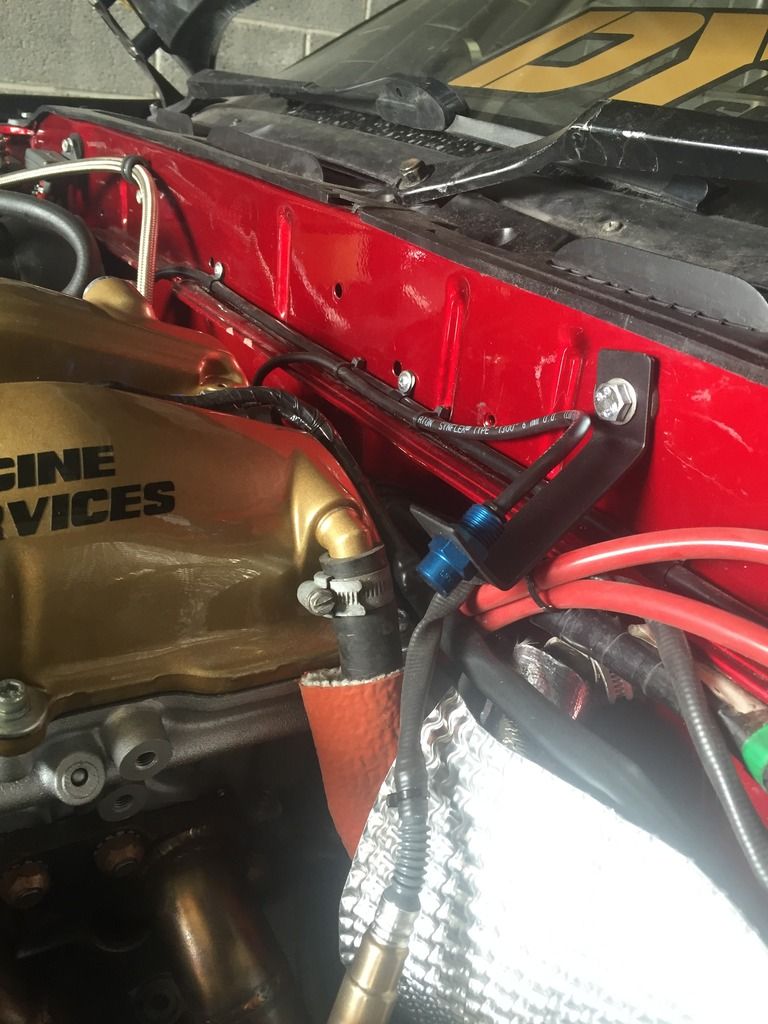

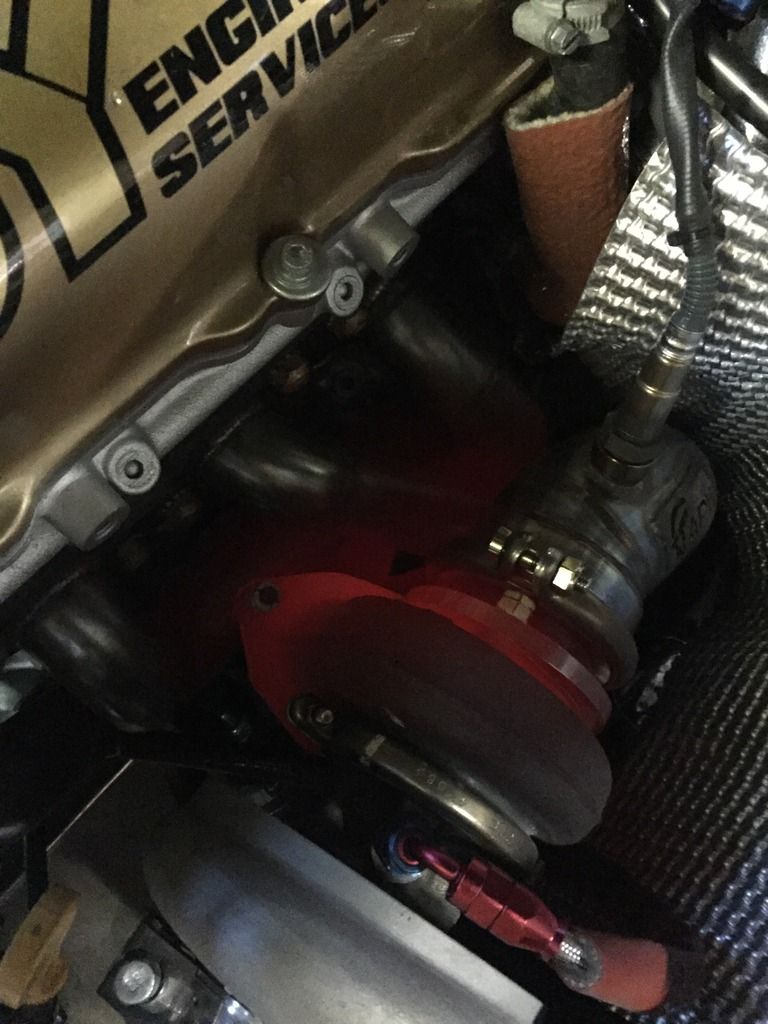

Here’s how the return feed now looks I think it looks pretty cool and its purposeful – it’s out of harms way and easy to access.

I think it looks pretty cool and its purposeful – it’s out of harms way and easy to access.

And here is the car in its natural habitat..

I spent a bit more time on the interior – which now resembles an S13! It’s cool that after all this time, it’s the final assembly stage where you see the bigger picture all come together. The more the interior comes together, the more time I want to spend in there!

I got the fuel rail back from the fabricators – with the bung welded in. Therefore, it’ll be leak free forever now! I could’ve preserved with trying to make the bung seal, but at the end of the day, I’m running an external FPR, so I’ll never need to use that port for a fuel pressure gauge. I washed the rail out countless times, blew it with the air lines just to make sure there is no debris in there. After all, a stupid mistake now could be costly.

And all back together, with no leaks * fingers crossed *..

A chap on Driftworks was selling S13 gauge holders that sit in the middle vents – something I’ve been after for ages. It’s such a clean way to display gauges in my opinion. It should just pop in, but I used a tiny bit of glue just to make sure it doesn’t vibrate loose or anything whilst out on track.

So the exhaust was too loud, more so for UK tracks where sound is becoming an ever bigger issue. So the Buddy Club unfortunately had to go I decided to go for a custom setup. Plus, the existing setup sat too close to the prop for my liking so I thought I’d kill 2 birds with 1 stone.

I decided to go for a custom setup. Plus, the existing setup sat too close to the prop for my liking so I thought I’d kill 2 birds with 1 stone.

I also had a couple of issues with the downpipe Hux made me – the rear flange had been warped – no gasket would ever seal, and the O2 sensor was quite tricky to access. So I ordered a Kinugawa TD06 to 3” V-Band adapter – therefore my new exhaust system would have V-bands all throughout for ease of maintenance. I have plans for swappable rear back boxes – one for making anti-social TD06 noises, the other being more sensible so I can get out on track.

I was still stoked the car had electrics – so took a picture of the sidelights – I’m not sure why to be honest haha!

I think I touched on it previously – but upon plumbing up the fuel rail I made the stupid mistake of plumbing the FPR before the fuel rail, rather than after! Got to make mistakes to learn ehh..

So here was our “bodge” to get the motor running late at night:

So I started stripping the fuel rail down – as a small 1/8NPT bung was continually leaking.

I tried everything bar PTFE tape to get this bung to seal. The idea of a small bit of PTFE breaking free in the fuel rail and clogging a fuel injector wasn’t something I wanted to happen – I want to try and get everything setup perfectly now so things wont go wrong in the future * touch wood * so I’ll just get it TIG’d up!

Whilst I was waiting for the local fabricator to free up some space to squeeze my fuel rail in, I ordered lots of vacuum hose in order to plumb everything up neatly.

(Red of course to match the bay!)

Whilst most people use cable ties or even nothing to hold their vac hoses onto the ports, this simply wouldn’t do for me

Not to worry, a bunch of constant tension clamps will make sure they are constantly sealed and wont pop off!

Not to worry, a bunch of constant tension clamps will make sure they are constantly sealed and wont pop off!

- - - Updated - - -

As a result of plumbing up the FPR incorrectly – I spent another small fortune on AN/Dash fittings plus braided hose. Anyone whose bought these fitting and lines will understand the cost of them!

Here’s how the return feed now looks

I think it looks pretty cool and its purposeful – it’s out of harms way and easy to access.

I think it looks pretty cool and its purposeful – it’s out of harms way and easy to access.

And here is the car in its natural habitat..

I spent a bit more time on the interior – which now resembles an S13! It’s cool that after all this time, it’s the final assembly stage where you see the bigger picture all come together. The more the interior comes together, the more time I want to spend in there!

I got the fuel rail back from the fabricators – with the bung welded in. Therefore, it’ll be leak free forever now! I could’ve preserved with trying to make the bung seal, but at the end of the day, I’m running an external FPR, so I’ll never need to use that port for a fuel pressure gauge. I washed the rail out countless times, blew it with the air lines just to make sure there is no debris in there. After all, a stupid mistake now could be costly.

And all back together, with no leaks * fingers crossed *..

A chap on Driftworks was selling S13 gauge holders that sit in the middle vents – something I’ve been after for ages. It’s such a clean way to display gauges in my opinion. It should just pop in, but I used a tiny bit of glue just to make sure it doesn’t vibrate loose or anything whilst out on track.

So the exhaust was too loud, more so for UK tracks where sound is becoming an ever bigger issue. So the Buddy Club unfortunately had to go

I decided to go for a custom setup. Plus, the existing setup sat too close to the prop for my liking so I thought I’d kill 2 birds with 1 stone.

I decided to go for a custom setup. Plus, the existing setup sat too close to the prop for my liking so I thought I’d kill 2 birds with 1 stone. I also had a couple of issues with the downpipe Hux made me – the rear flange had been warped – no gasket would ever seal, and the O2 sensor was quite tricky to access. So I ordered a Kinugawa TD06 to 3” V-Band adapter – therefore my new exhaust system would have V-bands all throughout for ease of maintenance. I have plans for swappable rear back boxes – one for making anti-social TD06 noises, the other being more sensible so I can get out on track.

I was still stoked the car had electrics – so took a picture of the sidelights – I’m not sure why to be honest haha!

Last edited:

200sx_

PS13 x TD Power

When Martin did the electrics, he forgot to bring an Intake Air Temp sensor – So I quickly popped it in when he had one.

To go with my Defi gauges, I ordered another vital gauge to go with them – An Air Fuel Ratio gauge so I can make sure the engine and tune are both happy.

Whilst I’m not strictly aiming for competition use – I wanted to run a fire extinguisher just in case something bad did happen – I can suppress it.

Plus an additional pull for external use..

The next step was to measure up the hydro lines – which Proline Motorsport made for me (the same chaps that made my custom brake lines). I cannot fault the quality, nor the price of their work

All fitted – with a bit of protective sleeving as they pass through the body of the car. Hopefully this means they wont chafe, and eventually leak – that’s the plan anyhow.

- - - Updated - - -

I’ve added a bit of padding to the roll cage – mainly in areas where contact is most likely. Better to be safer than sorry I guess!

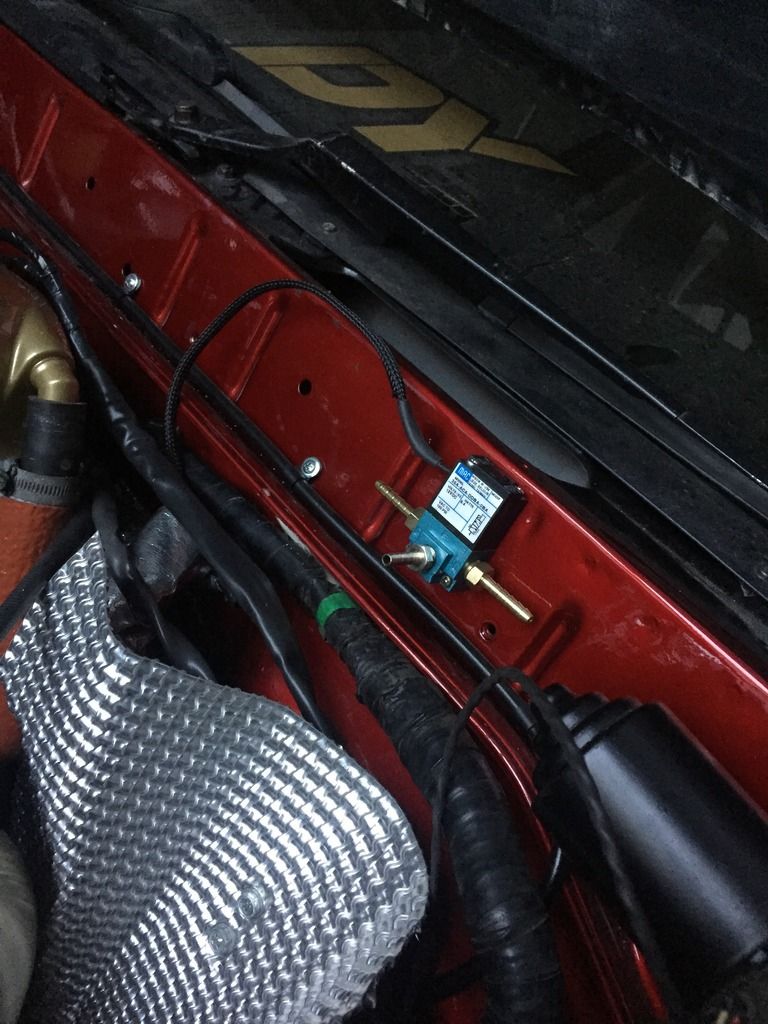

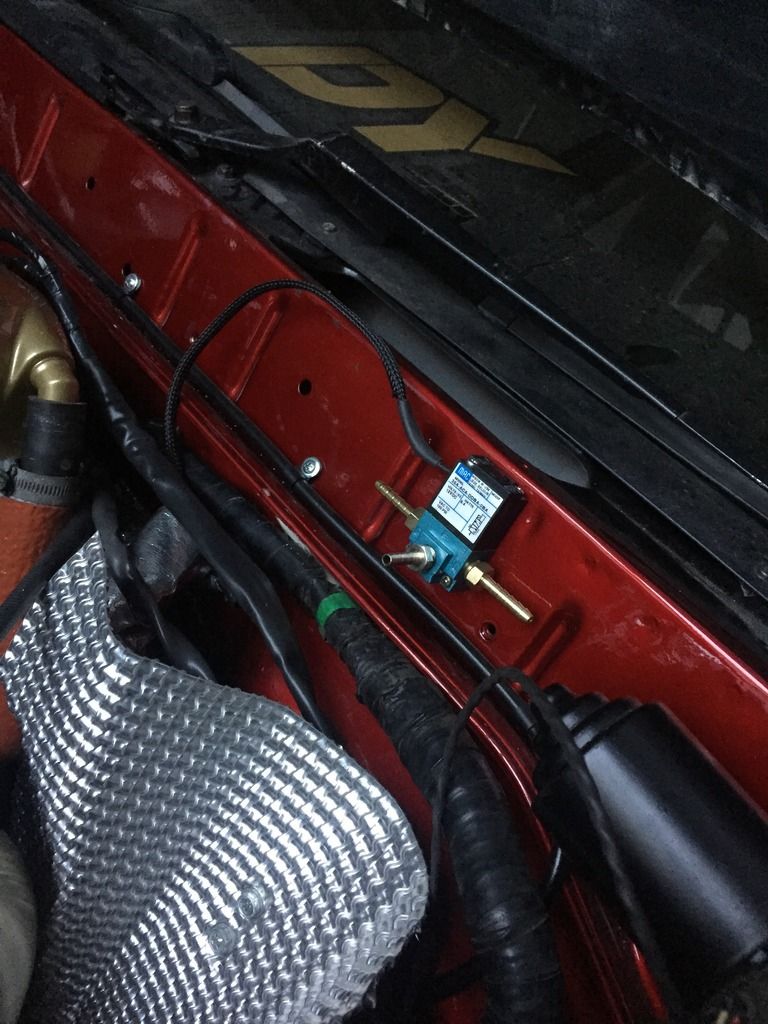

Next job was to mount the boost solenoid – my key aim was to get it out of harms way to avoid any dirt/debris and heat. So up on the bulkhead it went:

A photo of the interior as it stood:

- - - Updated - - -

I also made another purchase – this time a friend of mine was selling his Bride Zeta III with an S-Body passenger rail. It was a perfect opportunity to grab another seat and have a matching setup.

Whilst I obsessed about my new seat, a friend of mine quickly wired up my gauges. Every gauge sits within my view, with the important ones closer to me, so I can have a quick glance on the vitals.

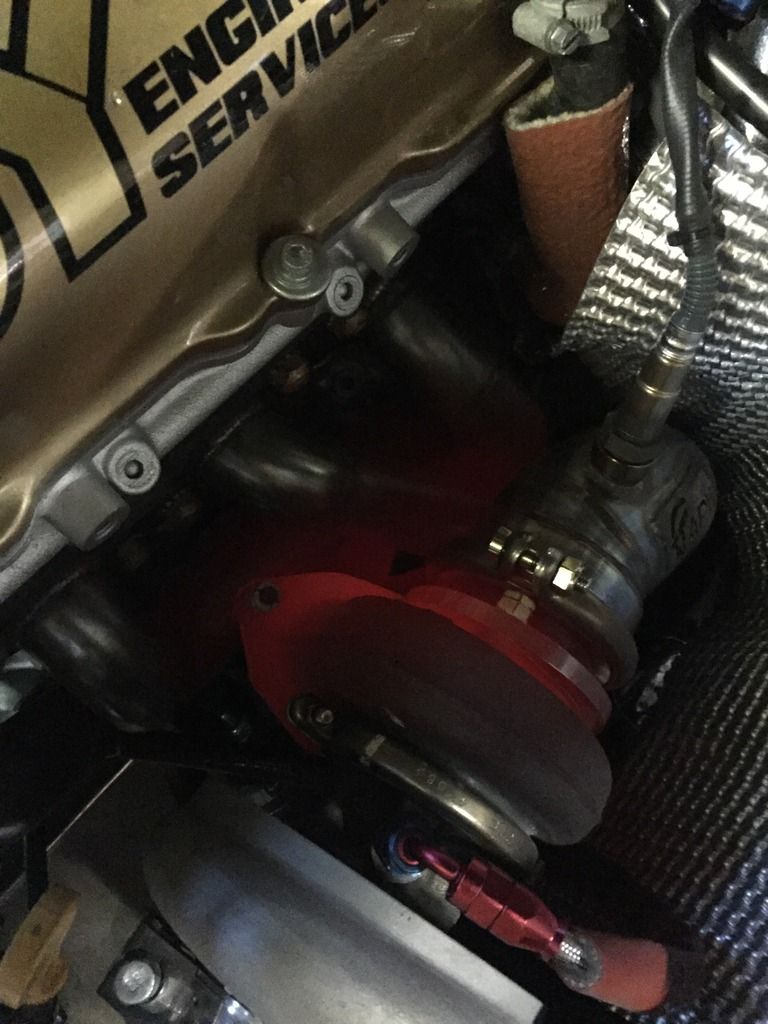

Plumbing up the external Wastegate was fairly simple – I ensured all the lines were routed as far away from heat as possible – to minimise the likelihood of any issues (I’ve heard many stories where incorrectly fastened vac hoses on wastegates lead to mushy pistons!) Each line was protected in heat sleeve, with a constant tension clamp to make sure they are correctly fastened.

And subsequently – the boost solenoid was all plumbed up too.

The interior kept coming together – and I fell in love with it even more!

I fastened the fire extinguisher down behind the passenger seat – my thinking here was to help offset my body weight, plus it was an area where I could make sure the extinguisher itself was fastened down to a standard that I was happy with. After all, in a crash an object of that size and weight could easily lead to a fatality.

Even the vacuum hose for the MAP sensor got a constant tension clamp – after all, it’s the small details that create the bigger picture.

It was my first time plumbing up a fire extinguisher – and it wasn’t that bad! Just cut to length and push fit until they click/lock into place. I thought I’d try and hide the lines under the centre console for a more discrete and subtle installation:

I mounted one nozzle towards my feet as per competition regulations, where I then set upon the installation of the pull handle in the cabin. I had a small brain wave (quite a rare thing ha!) and mounted it by the steering wheel – it’s easy to reach, subtle and not obtrusive The moulding of the cluster meant it was a tad tricky to mount, but the idea worked! I may come back to this in the future for a neater solution.

The moulding of the cluster meant it was a tad tricky to mount, but the idea worked! I may come back to this in the future for a neater solution.

To go with my Defi gauges, I ordered another vital gauge to go with them – An Air Fuel Ratio gauge so I can make sure the engine and tune are both happy.

Whilst I’m not strictly aiming for competition use – I wanted to run a fire extinguisher just in case something bad did happen – I can suppress it.

Plus an additional pull for external use..

The next step was to measure up the hydro lines – which Proline Motorsport made for me (the same chaps that made my custom brake lines). I cannot fault the quality, nor the price of their work

All fitted – with a bit of protective sleeving as they pass through the body of the car. Hopefully this means they wont chafe, and eventually leak – that’s the plan anyhow.

- - - Updated - - -

I’ve added a bit of padding to the roll cage – mainly in areas where contact is most likely. Better to be safer than sorry I guess!

Next job was to mount the boost solenoid – my key aim was to get it out of harms way to avoid any dirt/debris and heat. So up on the bulkhead it went:

A photo of the interior as it stood:

- - - Updated - - -

I also made another purchase – this time a friend of mine was selling his Bride Zeta III with an S-Body passenger rail. It was a perfect opportunity to grab another seat and have a matching setup.

Whilst I obsessed about my new seat, a friend of mine quickly wired up my gauges. Every gauge sits within my view, with the important ones closer to me, so I can have a quick glance on the vitals.

Plumbing up the external Wastegate was fairly simple – I ensured all the lines were routed as far away from heat as possible – to minimise the likelihood of any issues (I’ve heard many stories where incorrectly fastened vac hoses on wastegates lead to mushy pistons!) Each line was protected in heat sleeve, with a constant tension clamp to make sure they are correctly fastened.

And subsequently – the boost solenoid was all plumbed up too.

The interior kept coming together – and I fell in love with it even more!

I fastened the fire extinguisher down behind the passenger seat – my thinking here was to help offset my body weight, plus it was an area where I could make sure the extinguisher itself was fastened down to a standard that I was happy with. After all, in a crash an object of that size and weight could easily lead to a fatality.

Even the vacuum hose for the MAP sensor got a constant tension clamp – after all, it’s the small details that create the bigger picture.

It was my first time plumbing up a fire extinguisher – and it wasn’t that bad! Just cut to length and push fit until they click/lock into place. I thought I’d try and hide the lines under the centre console for a more discrete and subtle installation:

I mounted one nozzle towards my feet as per competition regulations, where I then set upon the installation of the pull handle in the cabin. I had a small brain wave (quite a rare thing ha!) and mounted it by the steering wheel – it’s easy to reach, subtle and not obtrusive

The moulding of the cluster meant it was a tad tricky to mount, but the idea worked! I may come back to this in the future for a neater solution.

The moulding of the cluster meant it was a tad tricky to mount, but the idea worked! I may come back to this in the future for a neater solution.

200sx_

PS13 x TD Power

After playing with the hydro handle, I discovered it kept fouling the centre console trim – so quickly setup upon rectifying this..

Now – I mentioned I bought another Bride Zeta III seat, so it was only right I got another set of Takata Harnesses.. right?! Most people sell fakes, and I hate fake items, especially with safety items like seats and harnesses. So I contacted the guys at GSM Performance (I originally bought my first Bride seat through these guys) and they hooked me up a killer deal! So a fresh pair of Takata’s were on their way to me.

They’re a slightly updated version compared to the ones I have – so these new ones will of course become mine/the driver’s set, whilst my others will now be used for the passenger side.

- - - Updated - - -

I noticed my rear lights behaved a bit oddly – as in when braking, one side dims/goes off. After looking at the wiring on the bulb holders, they look like they have been messed around with during their previous life. So I managed to find a set of PS13 rear lights with bulb holders in great condition. Hopefully, these will fix my light issue.

After rectifying the small issues found upon start up – I decided to crank it over. It ran, and idled ok.. but as soon as you apply any throttle – it just dies. Not good! Especially considering how well it ran previously, this wasn’t a part of the plan.

- - - Updated - - -

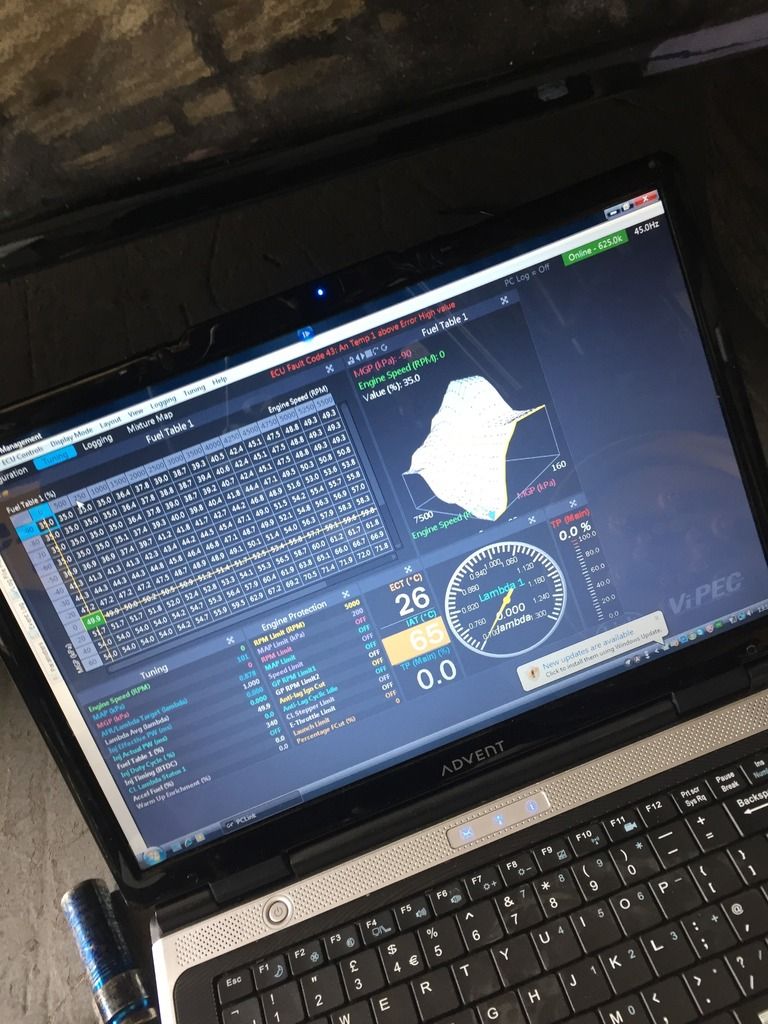

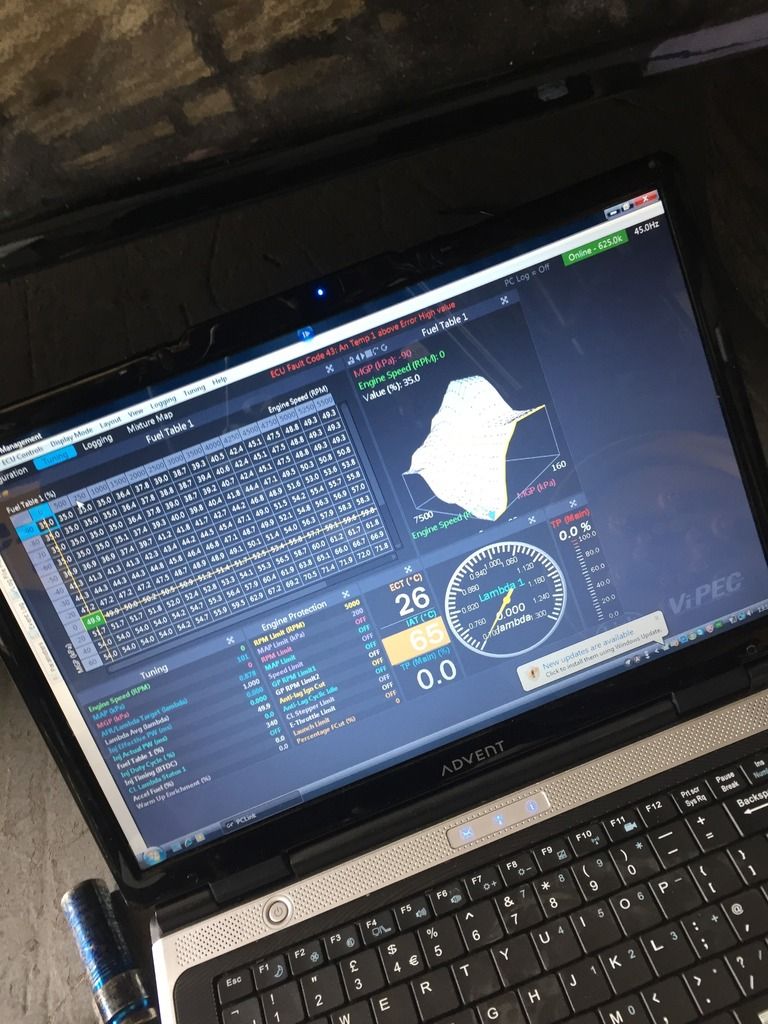

I downloaded the Link software and Teamviewer so Martin could check out what’s happening whilst he was more than likely sat in his hot tub, but in the end I ran out of time so we had to call it a day. But I did manage to see what the software and map looked like which was pretty cool!

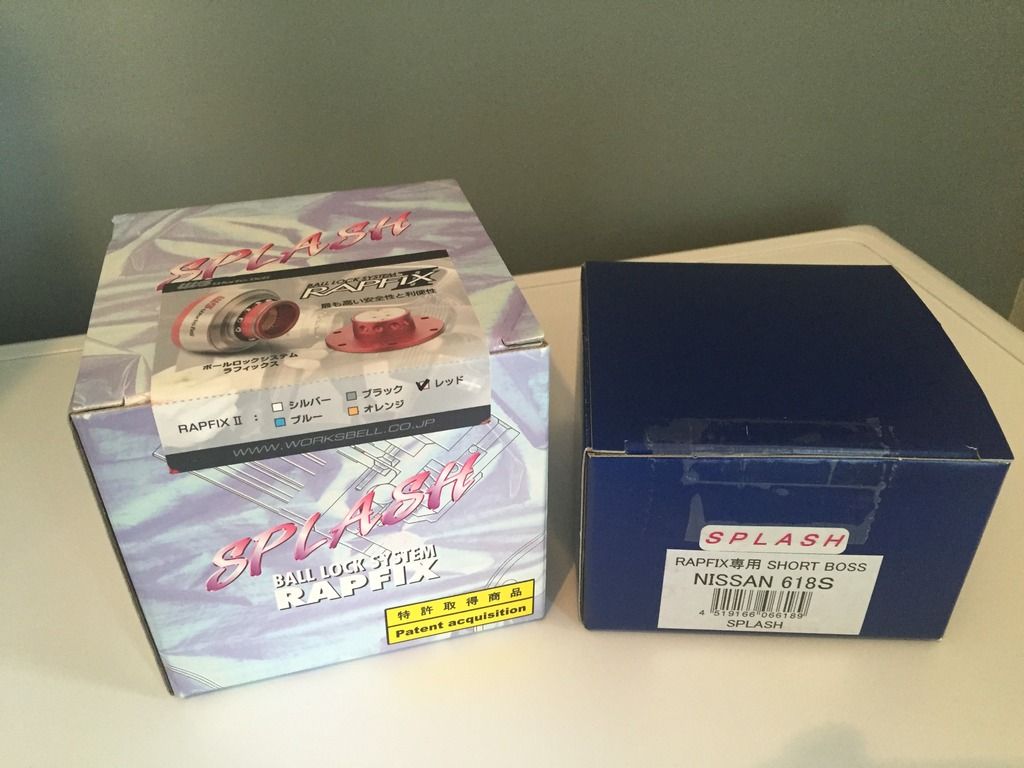

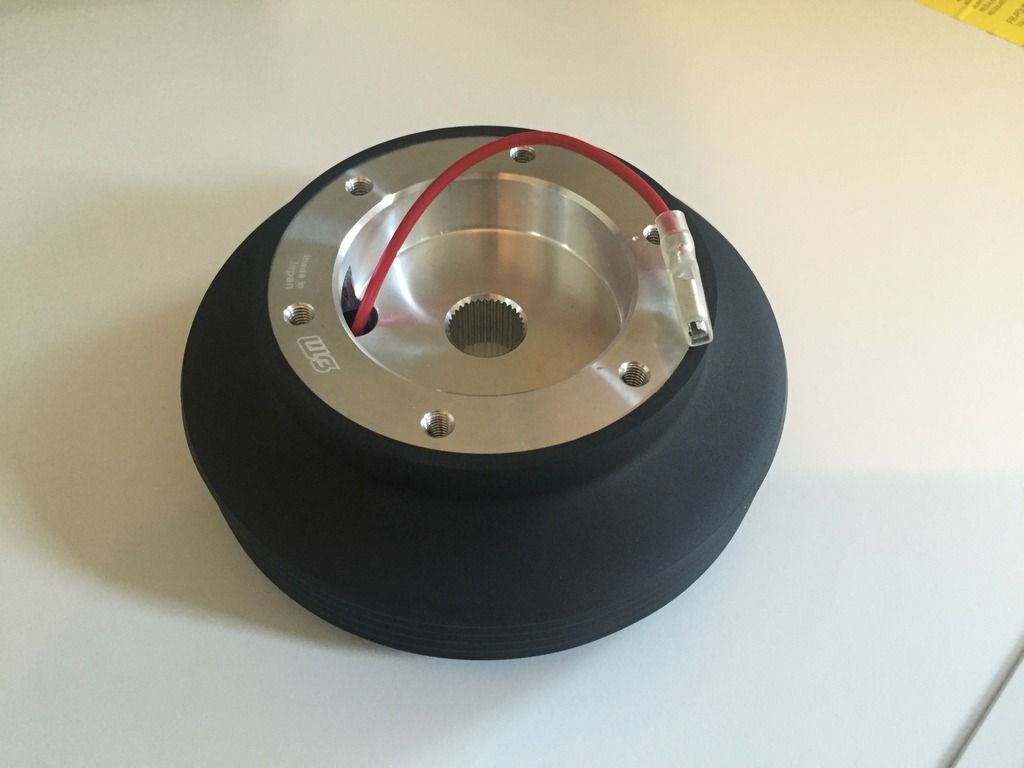

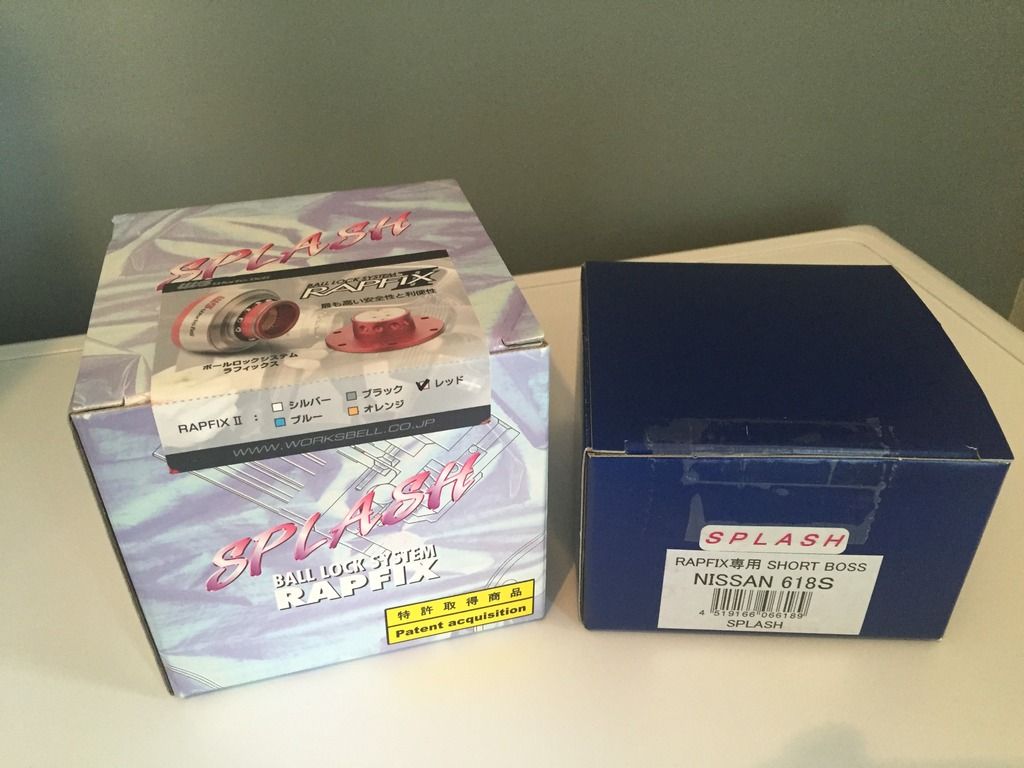

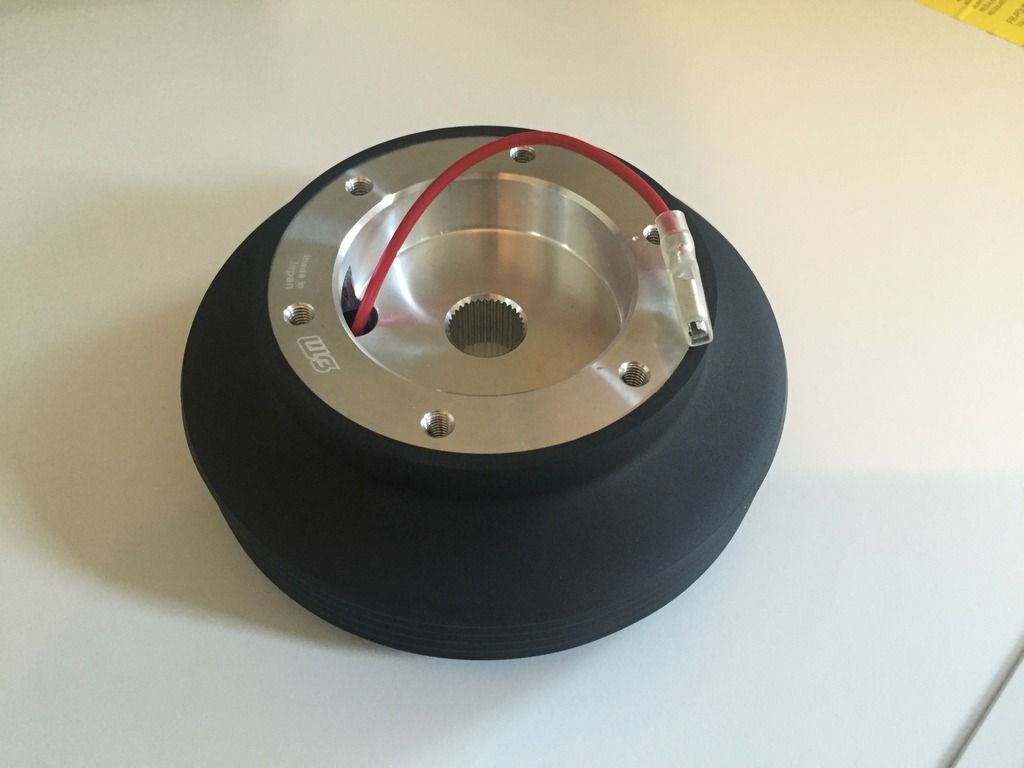

I’ve always wanted a snap off boss to make getting in and out of the car a bit easier, what with climbing over the roll cage. So I looked at my options – NRG seem okay, D1 seem a bit hit and miss etc, something I want to avoid considering it’s quite an important component at the end of the day. So, as always I decided to go all out and grab a Works Bell RAPFIX II snap off boss through Jesse Streeter. The quality is unreal, like literally unreal! The way the ball bearings click together is so satisfying, and even the way the splines are machined - a true testament to its quality!

Also, it had to be in red to complement the car.

Quickly installed it to see how it looks – I’m so pleased with it! Suits the interior down to a ground!

- - - Updated - - -

Took a few little photos of how the car stood – workshop started getting a little messy!

In between work – it was time to take my old mans Hot Rod to Huxley for a roll cage. This is something else I’ll be working on alongside the Silvia – so I’ll drop a few little updates on this as well.

2x Generations in one picture, Father/Son combination – such a cool comparison!

Anyway, back to mine!

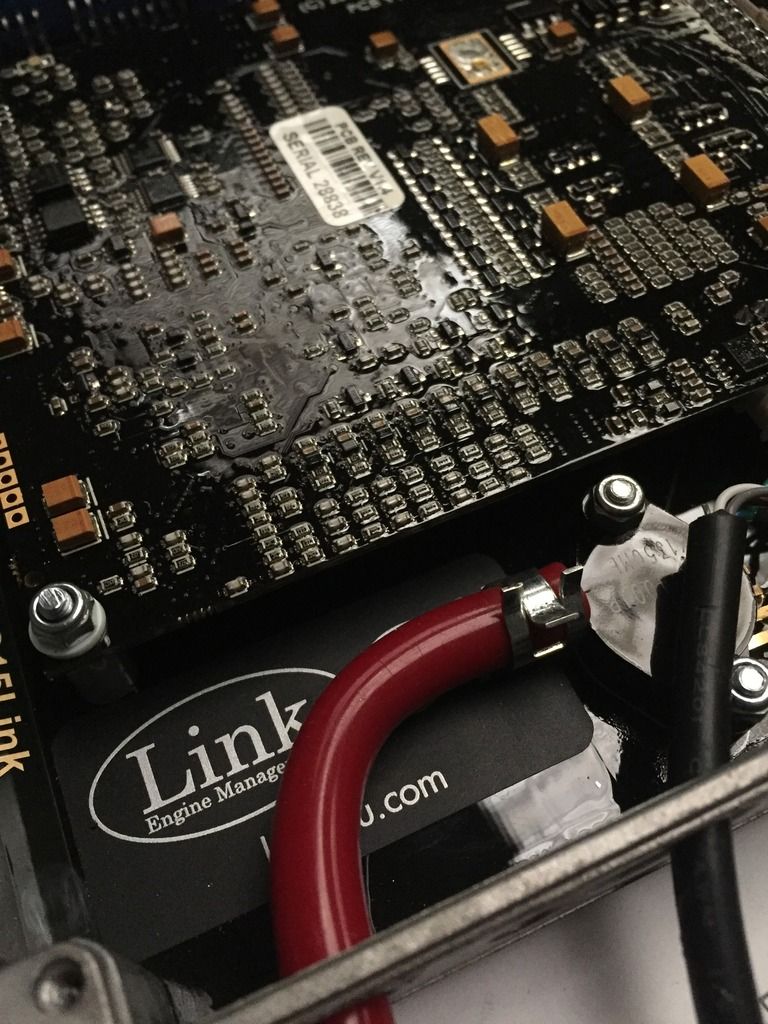

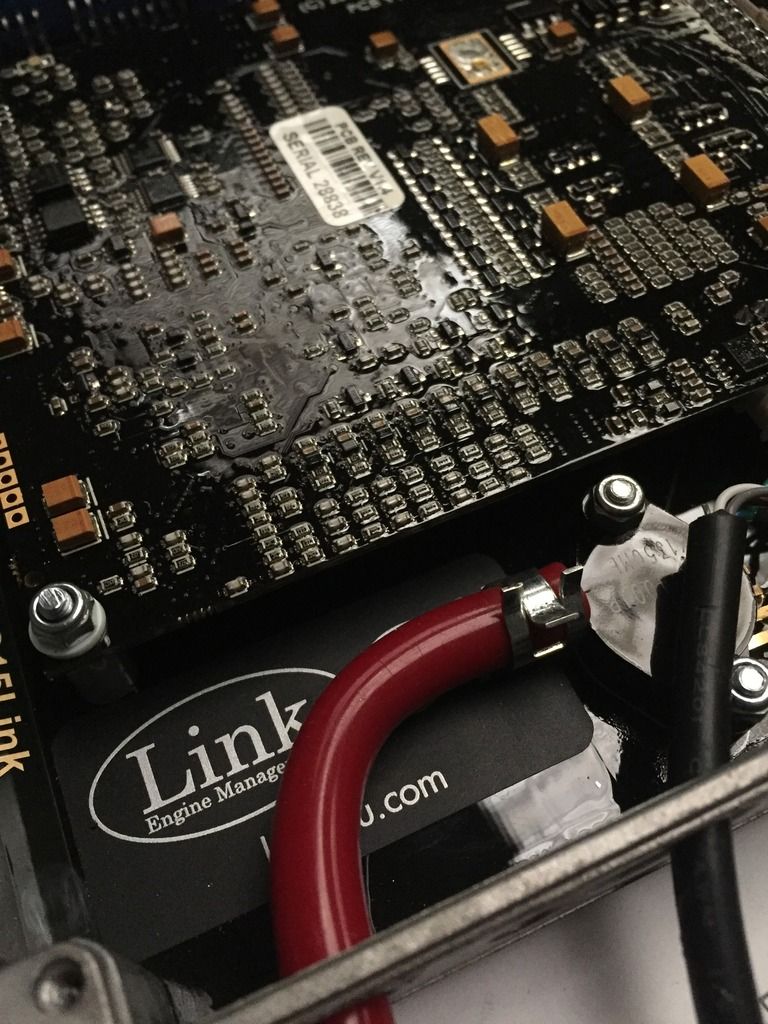

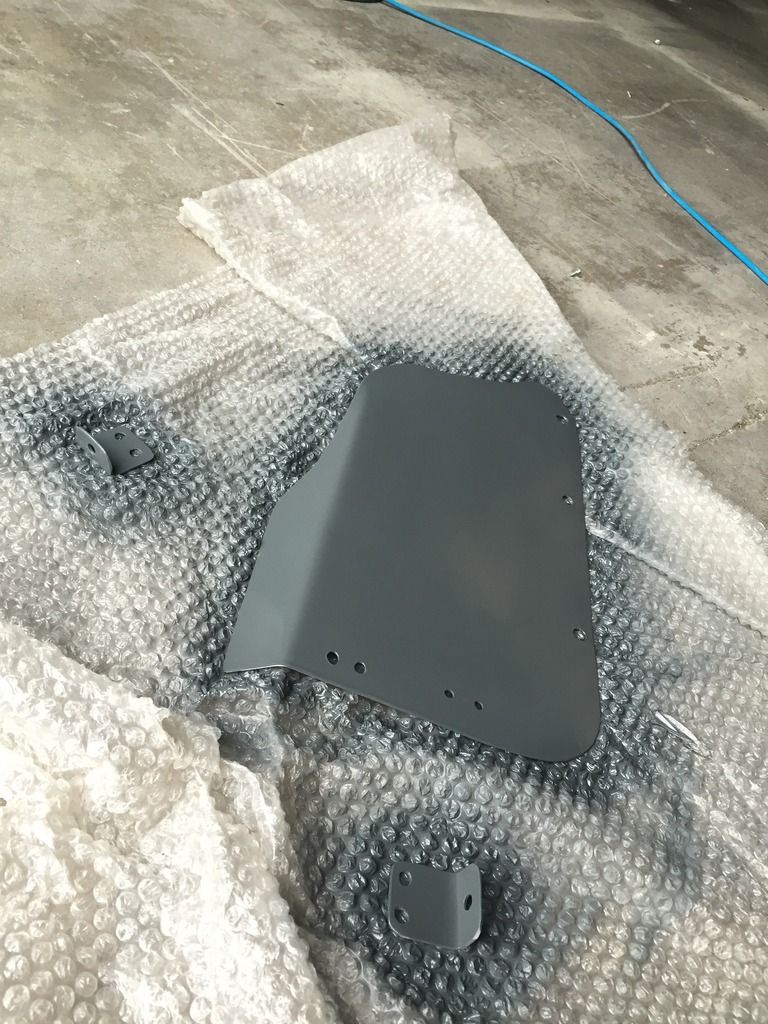

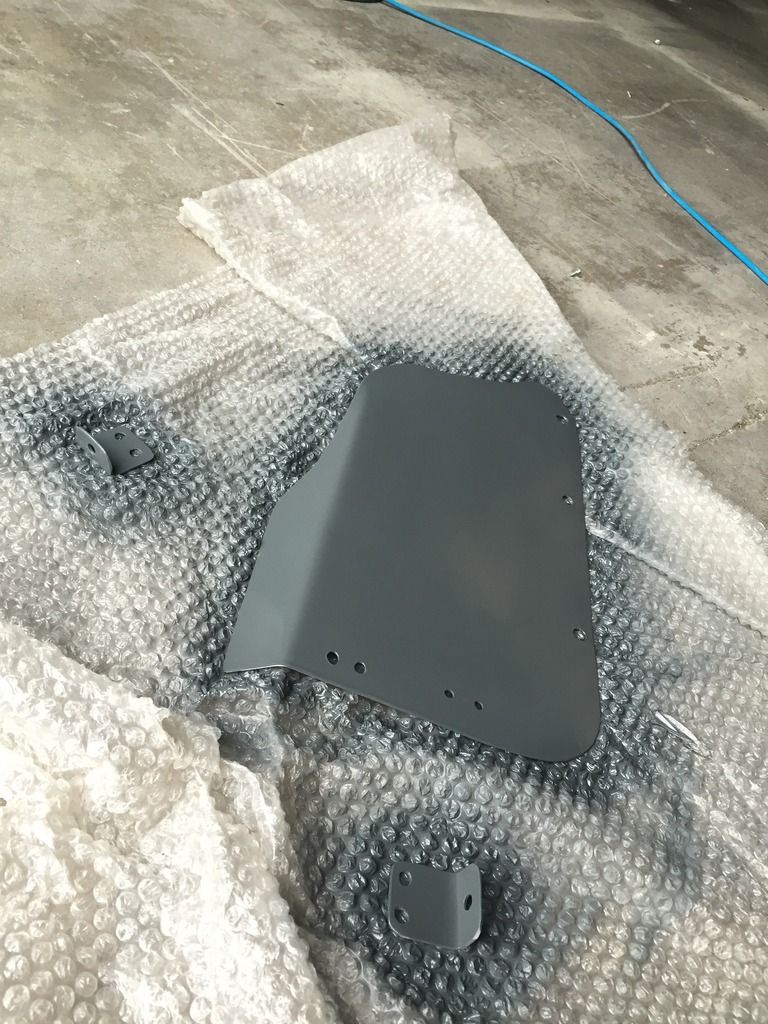

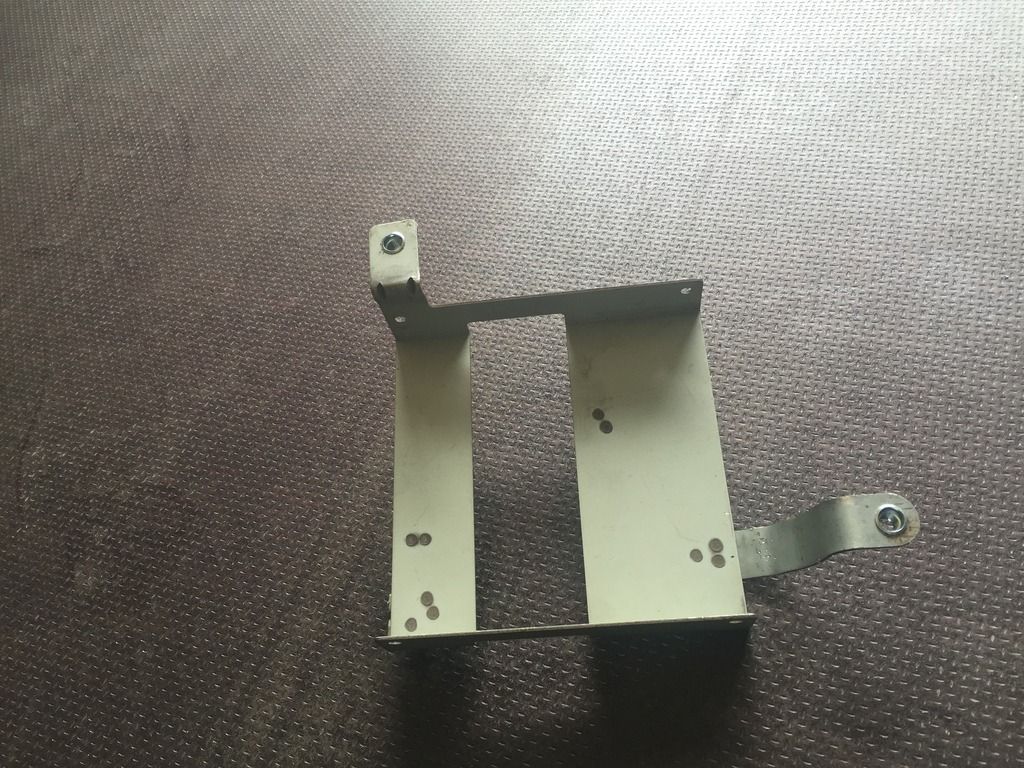

Due to the way the cage is tied in to the front turrets, it’s a bit hard to keep the factory ECU holder, and with a Link ECU (not exactly a cheap ECU!), I wanted to tuck it up out the way so it doesn’t get wet, nor kicked by any passengers. My solution was to make a removable plate that bolts into where the glovebox used to be, and where the ECU will be now be hidden behind.

A couple of Riv-Nuts into the factory casing allows my to bolt it onto my new cover thingy:

And here’s how it all assembles after paint

Now – I mentioned I bought another Bride Zeta III seat, so it was only right I got another set of Takata Harnesses.. right?! Most people sell fakes, and I hate fake items, especially with safety items like seats and harnesses. So I contacted the guys at GSM Performance (I originally bought my first Bride seat through these guys) and they hooked me up a killer deal! So a fresh pair of Takata’s were on their way to me.

They’re a slightly updated version compared to the ones I have – so these new ones will of course become mine/the driver’s set, whilst my others will now be used for the passenger side.

- - - Updated - - -

I noticed my rear lights behaved a bit oddly – as in when braking, one side dims/goes off. After looking at the wiring on the bulb holders, they look like they have been messed around with during their previous life. So I managed to find a set of PS13 rear lights with bulb holders in great condition. Hopefully, these will fix my light issue.

After rectifying the small issues found upon start up – I decided to crank it over. It ran, and idled ok.. but as soon as you apply any throttle – it just dies. Not good! Especially considering how well it ran previously, this wasn’t a part of the plan.

- - - Updated - - -

I downloaded the Link software and Teamviewer so Martin could check out what’s happening whilst he was more than likely sat in his hot tub, but in the end I ran out of time so we had to call it a day. But I did manage to see what the software and map looked like which was pretty cool!

I’ve always wanted a snap off boss to make getting in and out of the car a bit easier, what with climbing over the roll cage. So I looked at my options – NRG seem okay, D1 seem a bit hit and miss etc, something I want to avoid considering it’s quite an important component at the end of the day. So, as always I decided to go all out and grab a Works Bell RAPFIX II snap off boss through Jesse Streeter. The quality is unreal, like literally unreal! The way the ball bearings click together is so satisfying, and even the way the splines are machined - a true testament to its quality!

Also, it had to be in red to complement the car.

Quickly installed it to see how it looks – I’m so pleased with it! Suits the interior down to a ground!

- - - Updated - - -

Took a few little photos of how the car stood – workshop started getting a little messy!

In between work – it was time to take my old mans Hot Rod to Huxley for a roll cage. This is something else I’ll be working on alongside the Silvia – so I’ll drop a few little updates on this as well.

2x Generations in one picture, Father/Son combination – such a cool comparison!

Anyway, back to mine!

Due to the way the cage is tied in to the front turrets, it’s a bit hard to keep the factory ECU holder, and with a Link ECU (not exactly a cheap ECU!), I wanted to tuck it up out the way so it doesn’t get wet, nor kicked by any passengers. My solution was to make a removable plate that bolts into where the glovebox used to be, and where the ECU will be now be hidden behind.

A couple of Riv-Nuts into the factory casing allows my to bolt it onto my new cover thingy:

And here’s how it all assembles after paint

200sx_

PS13 x TD Power

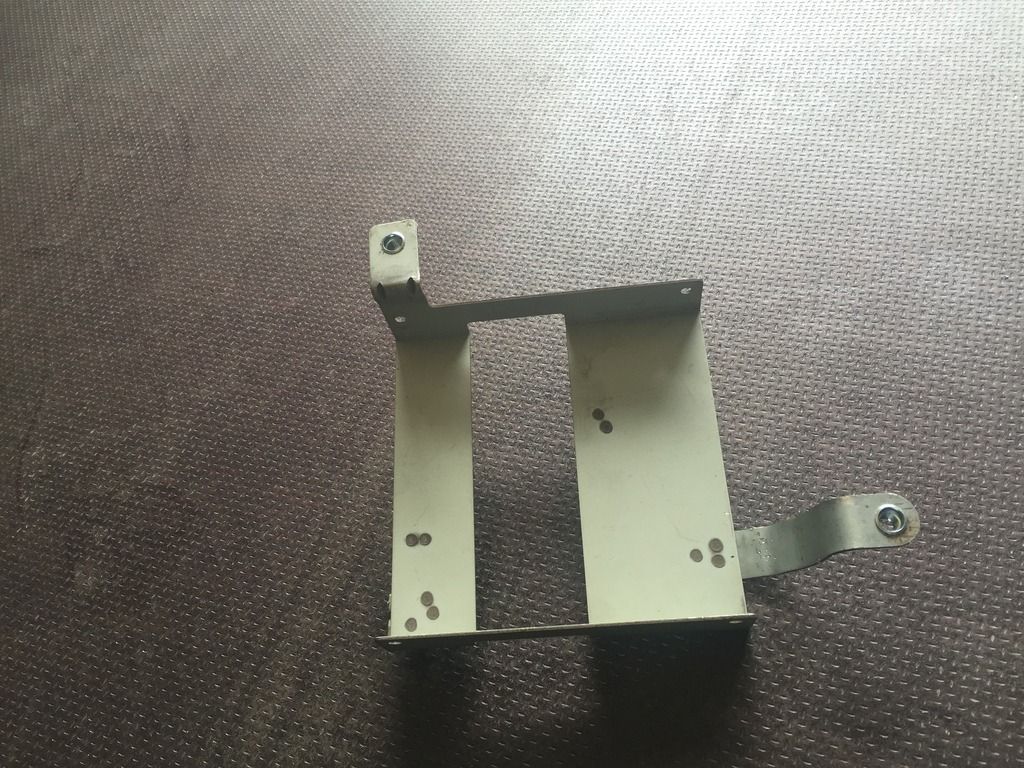

I touched upon it earlier, but I finally got around to creating a bracket for the external pull cables. They sit below the bonnet which is pretty neat as it helps keep a subtle look – I’m not into the full blown competition look personally.

Now it was time to take the Silvia on a little trip up to Andy @ APW Engineering – The same guy who built my manifold. He kinda loved my car and I wanted a new exhaust system, an area in which he is a fabrication wizard in! So I set upon the 4+ hour journey to Barnsley in the new tow vehicle.

HERE! I love how mean this thing looks on the trailer!

Off-loaded and ready for Andy to work his magic! It’s quite refreshing to meet a guy who’s passionate about his work – gives me a lot of confidence in the job he’ll do.

- - - Updated - - -

Here’s how the car looks before Andy works his magic!

And here’s the work he’s done – it’s literally incredible! The concept was simple, but I let Andy loose with what he thinks works best. 3” from the turbo back, V-bands throughout with swappable rear boxes (3” Shotgun vs. 4” Turn Down)

- - - Updated - - -

Words literally couldn’t describe how happy I am with his work – even the way he has made each and every V-band leak proof is insane. Now it’s time for the 4 hour journey back home!

Back home – I had a little tidy up whilst the car was away.

Now it was time to take the Silvia on a little trip up to Andy @ APW Engineering – The same guy who built my manifold. He kinda loved my car and I wanted a new exhaust system, an area in which he is a fabrication wizard in! So I set upon the 4+ hour journey to Barnsley in the new tow vehicle.

HERE! I love how mean this thing looks on the trailer!

Off-loaded and ready for Andy to work his magic! It’s quite refreshing to meet a guy who’s passionate about his work – gives me a lot of confidence in the job he’ll do.

- - - Updated - - -

Here’s how the car looks before Andy works his magic!

And here’s the work he’s done – it’s literally incredible! The concept was simple, but I let Andy loose with what he thinks works best. 3” from the turbo back, V-bands throughout with swappable rear boxes (3” Shotgun vs. 4” Turn Down)

- - - Updated - - -

Words literally couldn’t describe how happy I am with his work – even the way he has made each and every V-band leak proof is insane. Now it’s time for the 4 hour journey back home!

Back home – I had a little tidy up whilst the car was away.

200sx_

PS13 x TD Power

- - - Updated - - -

URL=http://s954.photobucket.com/user/200sx_photo/media/PS13/B6D8C225-1F47-4EF1-89BD-9623F167CBF9_zpsxuoibkem.jpg.html]

Next change was the diff ratio – the 4.36 is quite simply too high for a Z33/350z gearbox. After speaking to a couple of guys, and using a gear ratio calculator – I settled for a 4.08 ratio. It might not seem like a huge jump, but by my calculations this should mean the car would primarily be in 3rd and 4th gear, perfect! Now it was time to try and find a diff!

Luckily the guys at Garage D had a virgin R32 GTST VLSD diff which would be a perfect base for building a new diff. Whilst my old Nismo worked a treat, with all the work that’s gone into the car, I wanted to build a fresh diff with the correct tolerances to help save driveshafts and my gearbox, not to mention a consistent performance on track.

So, the diff arrived:

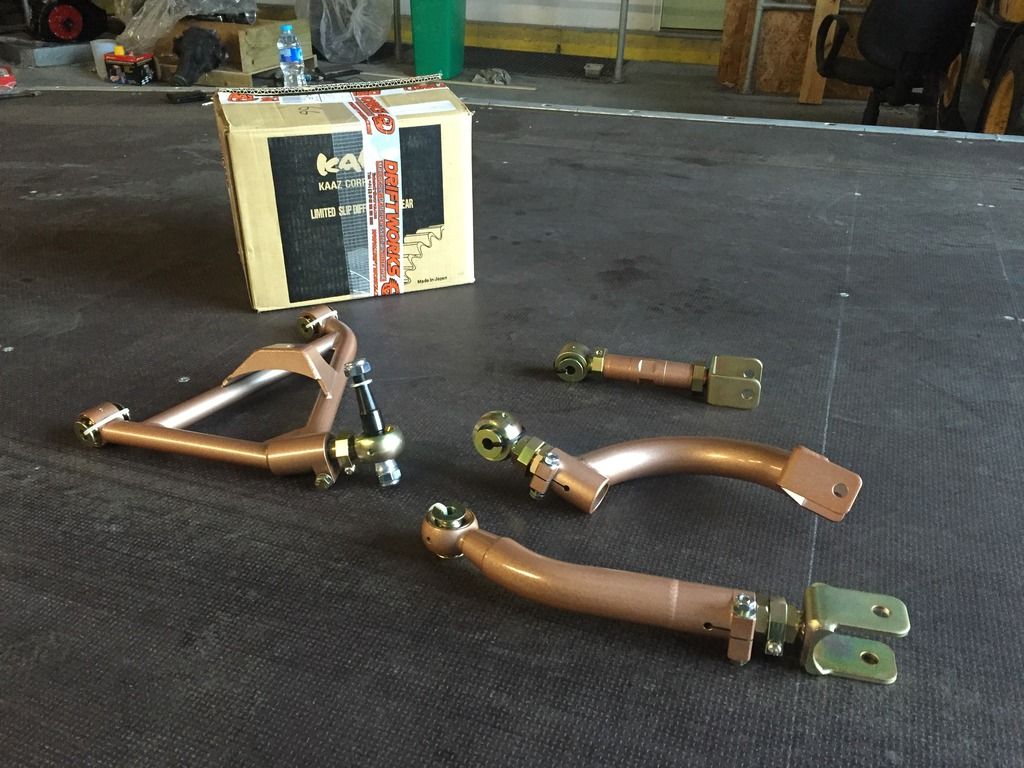

As for the internals – I settled on a Kaaz 2-Way Super Q diff from Driftworks. I’ve heard very positive things about the Kaaz units – mainly that they are an aggressive unit which suits track drifting.

The next step is to get the unit built professionally. A local place quoted me a stupid price, to the point I thought the quote included removing and fitting the diff from the car! Luckily enough, Martin @ MB Automotive is a dab hand at a range of things, and he said he’d build it for me. Perfect!

The next thing on my list is to finish off plumbing the fire extinguisher in the engine bay. Most regulations state the nozzle should point at the fuel rail, but I took the initiative to mount the nozzle towards the turbo – the main source of heat and the most likely place for a fire in my opinion. If, and when the time comes I need to pass scrutineering for competition, I can add in another nozzle.

- - - Updated - - -

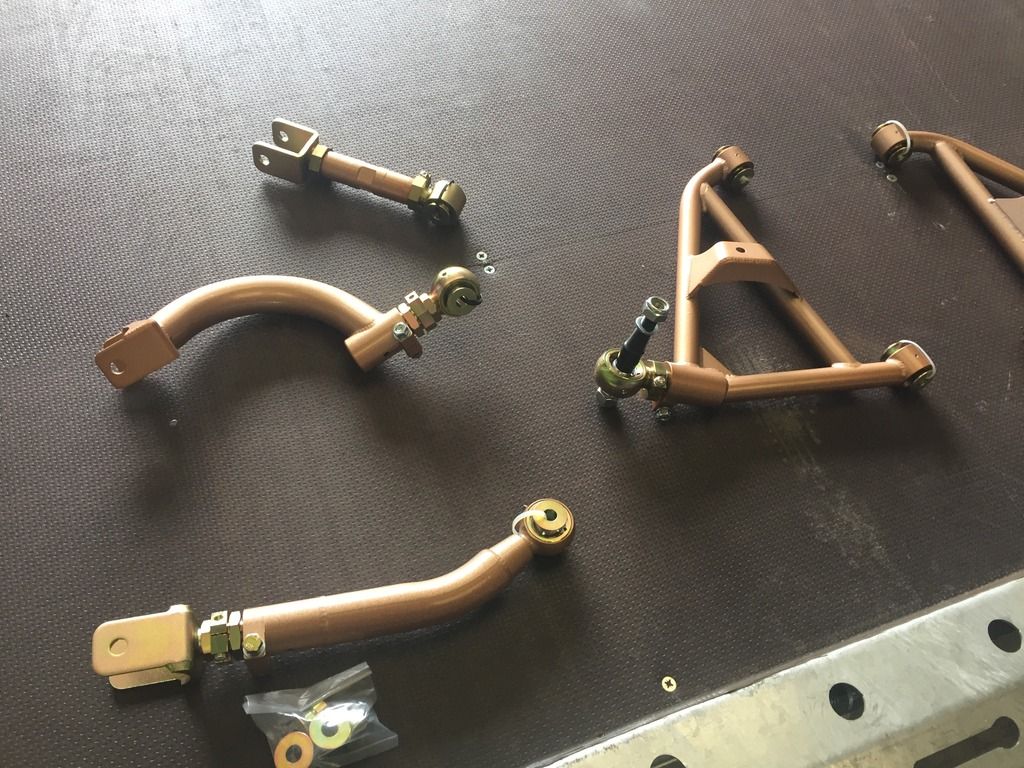

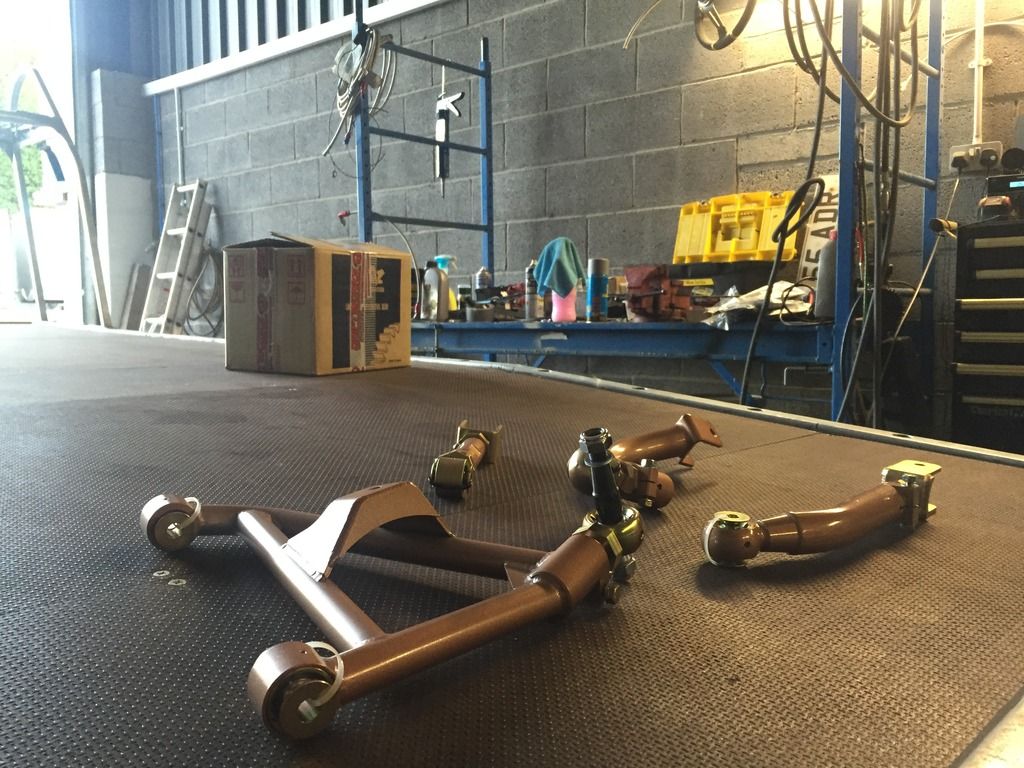

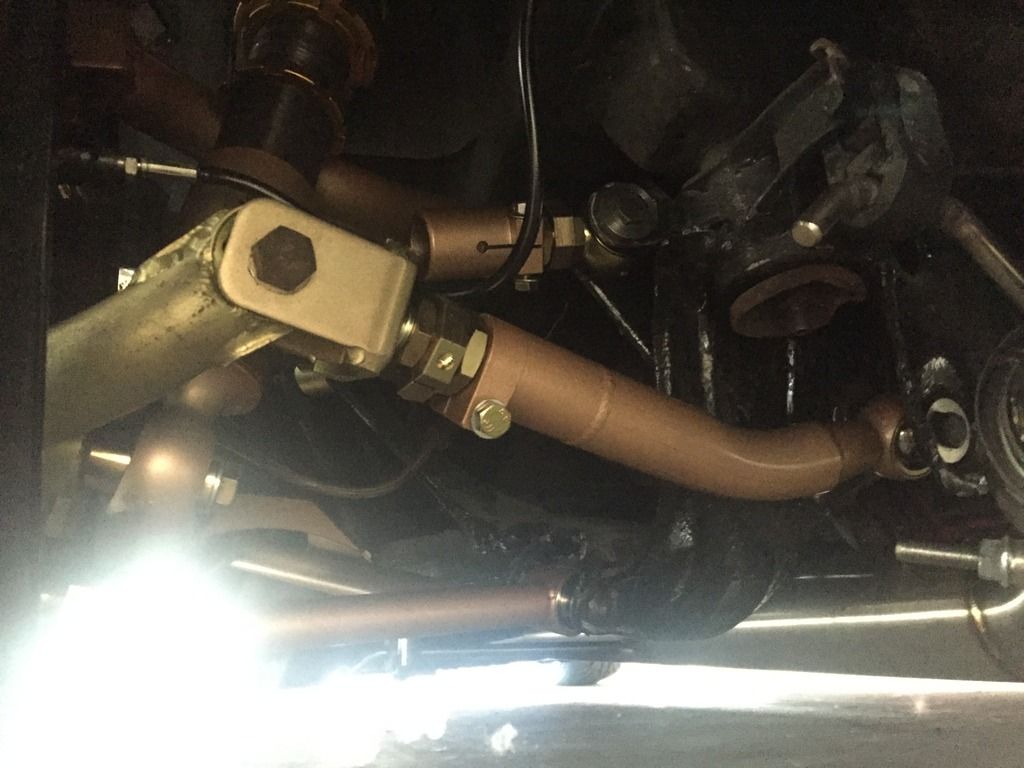

After looking at the rear of the car, I decided to spoil the car yet again! This time, another ordered was placed with Powered by Max. This time for rear alignment arms and rear lower control arms. As with the other PBM items, the quality is nothing short of spectacular! Prepare for lots of pictures!

PS: Trailers make excellent tables!

- - - Updated - - -

I was going to wait until after mapping to fit these, but with life getting in the way and mapping not being as soon as I’d like – I couldn’t help myself and started to fit them

200sx_

PS13 x TD Power

PBM RLCA vs Nissan Items:

PBM vs Hard Race Alignment Arms:

Aaaaaand back on the ground!

It’s a terrible picture, but kind of shows just how much clearance these arms offer!

I noticed the turbo drain flange was weeping, something I’d rather fix sooner rather than later! So off it all came, and resealed for good!

- - - Updated - - -

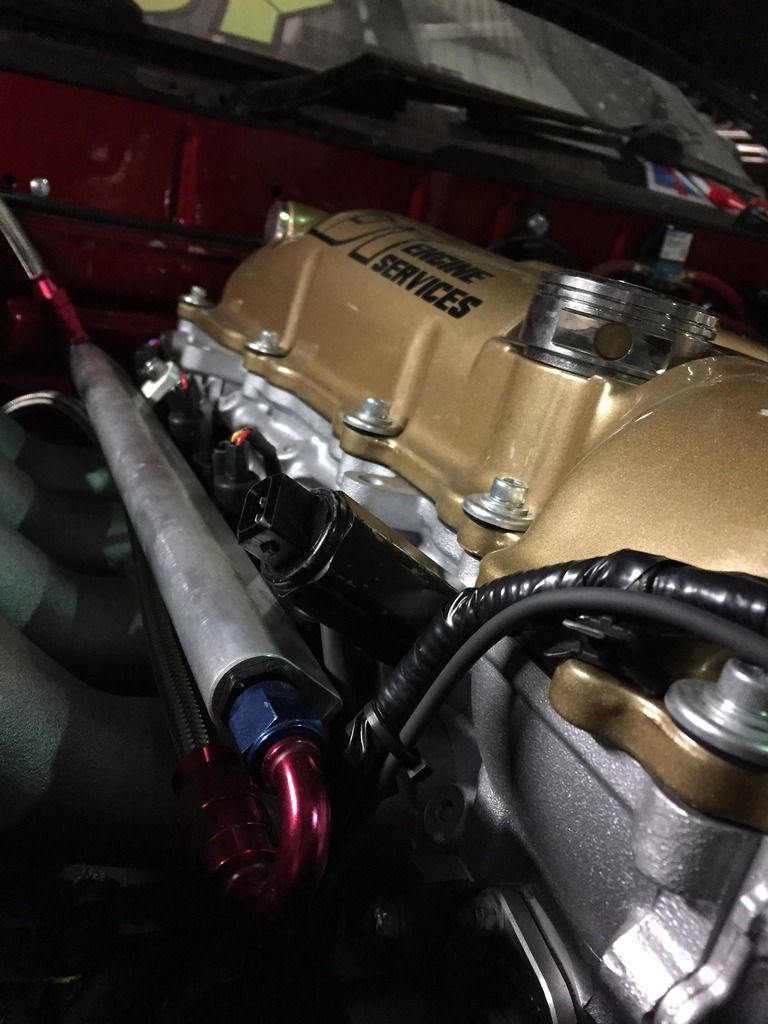

Obligatory pictures of the engine bay/car – I love how simple and purposeful this engine bay is though!

- - - Updated - - -

Whilst we had some nice weather for a change, I took even more photos of the car. Ya know, if I stopped taking so many photos – this car would probably be finished haha! Anyway:

This thing looks so sinister!

200sx_

PS13 x TD Power

Before I took the car to mapping – the engine builder contacted me about the VVT solenoid blank we had made up. We had concerns whether it was long enough to maintain oil pressure in the head. So as a safety measure, Dave gave me a VVT Solenoid I could use! Thankfully it was already black, so it’s a bit discrete.

Time to load it up for mapping! Martin came down the night before to check the car over. He altered the tune and everything ran spot on. The only reason we could think of as to why the car wouldn’t rev was because of the injector duty cycles. When we first got the car running, there was a fuel leak, so MB compensated with high injector cycles. So once the leak was fixed, it was running way too rich, hence why it would just die.

This was my first time driving the car around the yard, a bit of a milestone

Saw a few cool cars at JDM Garage – Paul’s S14a with a Mazworx stroked SR22 was pretty cool!

- - - Updated - - -

Off to the rolling road we go!

First off – it was time to run the motor in. To say I was nervous was a huge understatement! It’s been such a long time coming, I was constantly thinking whether every nut and bolt was done up correctly, every line flows nicely and correctly etc. The only issue was the rear end being a bit “bouncy”, I can only think this is due to the eye-ball alignment and unbalanced rear wheels with budget tyres.

Everything just seemed to work – it was odd and made me question everything even more! There was a bit of smoke for the first 10 minutes or so as oil and other residues burn off as I’ve touched things assembling it all. The motor ran perfectly, water temps were a bit high but that was down to the water system slowly bleeding itself. The other issue was there was a small drip underneath the engine/gearbox area, which kinda worried me. To begin with, it was a small, steady drip where the bellhousing meets the engine.

- - - Updated - - -

First impression was that it was the gearbox leaking near the front cover. After all, I had stripped the box down to machine the bellhousing etc. But after speaking to a few friends it doesn’t seem to be gear oil, more so engine oil. Hmmm!

Paul @ JDM Garage was in charge of running the engine in. And his comments were positive as he started edging the motor on boost. MB’s way of running the motor in was simple. Start as you mean to go on, making the rings bed the bores hard! Paul comments were mainly about how soon the motors wants to come on boost, positive signs to come!

It was so good to hear the car run! Next up was to do an oil and filter change before Martin starts to wind the motor up!

- - - Updated - - -

The oil that came was crisp and clean which is an encouraging sign that the motor is happy.

Whilst my car was sat outside and Paul S14a was being mapped, I grabbed a few pictures:

Mine and Paul’s SR22 S14a – it’s quite cool how two cars from opposite ends of the country come together and share similar ideas!

Time to load it up for mapping! Martin came down the night before to check the car over. He altered the tune and everything ran spot on. The only reason we could think of as to why the car wouldn’t rev was because of the injector duty cycles. When we first got the car running, there was a fuel leak, so MB compensated with high injector cycles. So once the leak was fixed, it was running way too rich, hence why it would just die.

This was my first time driving the car around the yard, a bit of a milestone

Saw a few cool cars at JDM Garage – Paul’s S14a with a Mazworx stroked SR22 was pretty cool!

- - - Updated - - -

Off to the rolling road we go!

First off – it was time to run the motor in. To say I was nervous was a huge understatement! It’s been such a long time coming, I was constantly thinking whether every nut and bolt was done up correctly, every line flows nicely and correctly etc. The only issue was the rear end being a bit “bouncy”, I can only think this is due to the eye-ball alignment and unbalanced rear wheels with budget tyres.

Everything just seemed to work – it was odd and made me question everything even more! There was a bit of smoke for the first 10 minutes or so as oil and other residues burn off as I’ve touched things assembling it all. The motor ran perfectly, water temps were a bit high but that was down to the water system slowly bleeding itself. The other issue was there was a small drip underneath the engine/gearbox area, which kinda worried me. To begin with, it was a small, steady drip where the bellhousing meets the engine.

- - - Updated - - -

First impression was that it was the gearbox leaking near the front cover. After all, I had stripped the box down to machine the bellhousing etc. But after speaking to a few friends it doesn’t seem to be gear oil, more so engine oil. Hmmm!

Paul @ JDM Garage was in charge of running the engine in. And his comments were positive as he started edging the motor on boost. MB’s way of running the motor in was simple. Start as you mean to go on, making the rings bed the bores hard! Paul comments were mainly about how soon the motors wants to come on boost, positive signs to come!

It was so good to hear the car run! Next up was to do an oil and filter change before Martin starts to wind the motor up!

- - - Updated - - -

The oil that came was crisp and clean which is an encouraging sign that the motor is happy.

Whilst my car was sat outside and Paul S14a was being mapped, I grabbed a few pictures:

Mine and Paul’s SR22 S14a – it’s quite cool how two cars from opposite ends of the country come together and share similar ideas!

Last edited:

200sx_

PS13 x TD Power

Here’s a cool photo I grabbed after a dyno run! Shows what kind of heat goes through the manifold

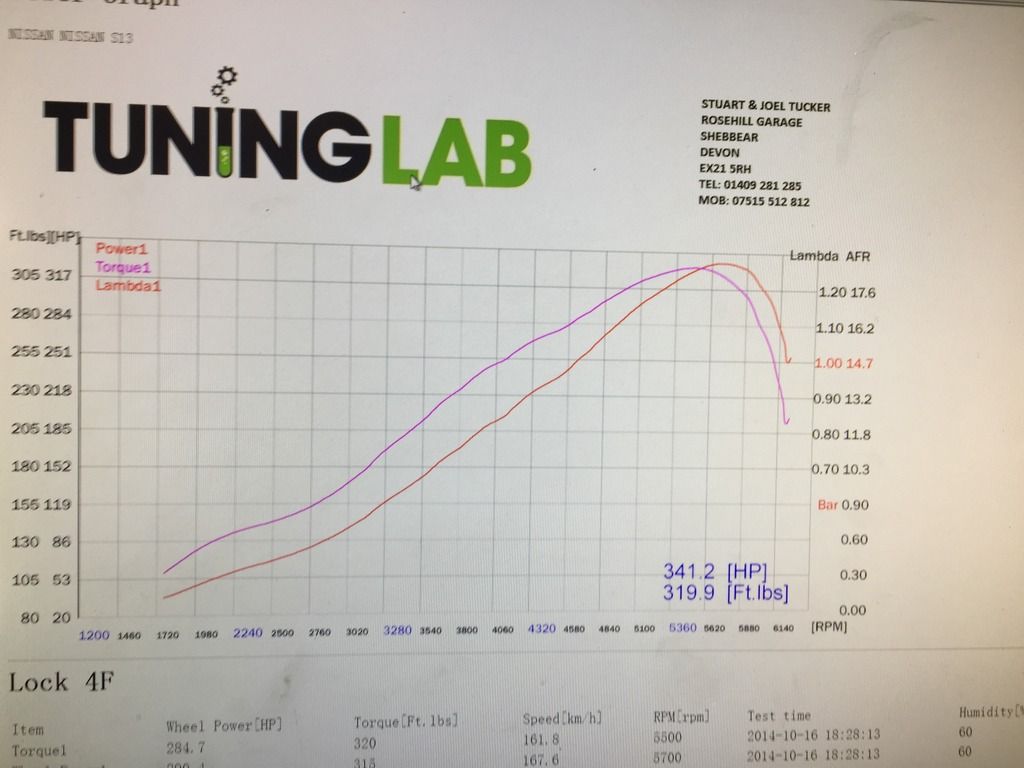

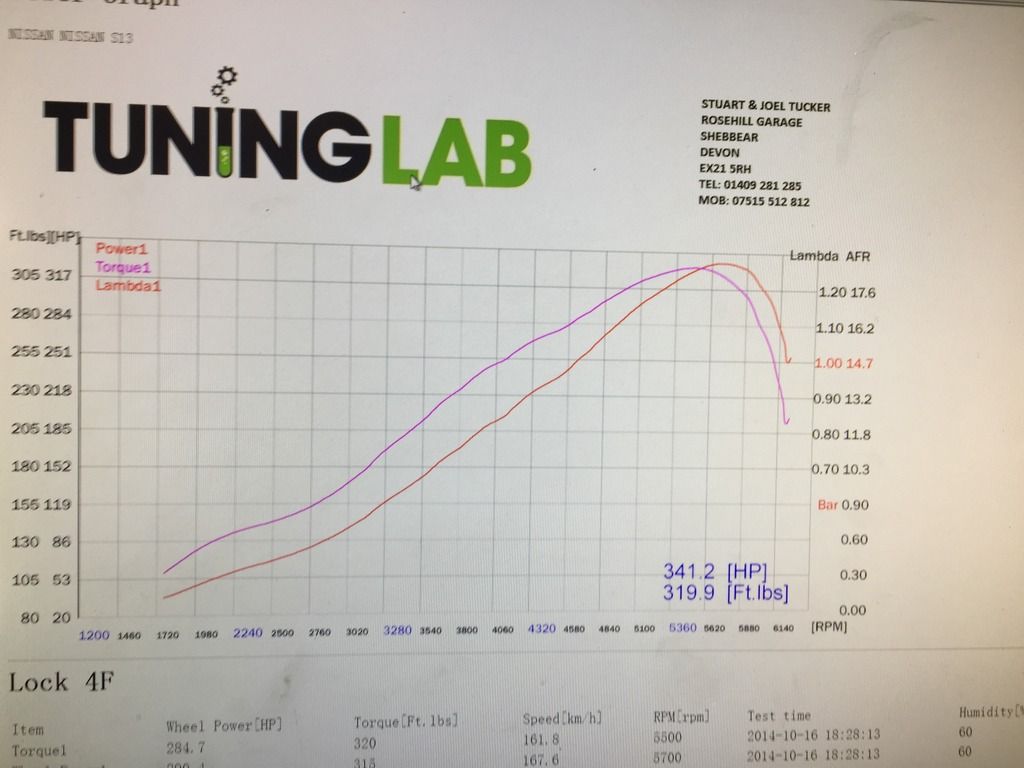

And here’s the picture you’ve all been waiting for:

First of all – you’ll all look at the power figure and think that’s fairly low. and so did I. A TD06 at 1.4bar/20psi should be over 400hp on a strong motor! I was a bit underwhelmed/disappointed to be honest. I built the whole setup to flow and work together, so an aim of 400whp would be quite a realistic goal. As for the low power figure, we’re not entirely sure either. The way the car pulled on the dyno was nothing like a 340hp motor; it’s nothing short of savage.

The obvious theory is the dyno – as we all know, dyno’s vary from place to place. But Paul SR22 made 500hp previously, which is the power region his setup should be making. Could it have been in a wrong mode? Or was the car strapped incorrectly – as this can play with the power figures also..

The next idea was the rear alignment – with the wheels potentially pulling in different directions, could that affect the end power reading? Or the bouncy rear end – could that have meant the full power wasn’t being put down?

The motor seems to breathe nicely – it has perfect AFR’s across the entire rev range up to the 7600 rev limit. We pulled the plugs out after mapping to check them, and all of them have a super clean & equal burn.

If I remember correctly, Paul’s car made 500+hp at 74(?)% injector duty cycle – mines running 62% so it’s not a mile off. Martin did the maths – a combination of using the amount of fuel the engine is taking, and multiplying it by the amount of horsepower the SR uses (this is probably incorrect, but he did some mathematical wizardry) and said the engine is taking enough fuel for the 420hp mark. Odd! He told me to have faith that it’s 400hp setup – so the plan is to take it out on track and see just how hard it pulls!

The cool thing about the graph is how linear it is - TD06’s are notoriously “laggy”. Not on this motor It comes on boost fast and hard, more encouraging signs it’s a strong and well built motor!

It comes on boost fast and hard, more encouraging signs it’s a strong and well built motor!

The noise this thing makes is crazy. Like really crazy. Paul’s S14a was pretty damn loud, but this thing on full chat was on another level. The sound is literally to die for, it has a very angry and purposeful TD06 sound to it.

In regards to the oil leak mentioned earlier – I noticed that after the oil change it was much less frequent than before. My thoughts were now the rear crank seal, perhaps the mineral oil was too thin when warm and passing through a seal? However, there was still a slight drip when running 15w50 synthetic oil. I could either leave it be, and hope for the best. Or remove the gearbox and re-seal the area. Personally, I think the latter is the most likely option. I just don’t want to risk ruining a clutch nor an engine over a leak.

So after a really really long day – I finally made it home after battling torrential rain, Devon’s finest inclines in the dark!

- - - Updated - - -

I didn’t get home until the early hours of the morning – so set upon unloading it the following morning. What a contrasting day in terms of the weather!

Another theory was the cam timing – maybe it could have been off due to the VVT Delete – but Dave and Martin checked this after mapping to which its perfect.

My freshly built 4.08 vs my old Nismo 4.36:

- - - Updated - - -

Now mapping had finished – I could finally lower the rear end! (I really couldn’t tell you how much I wanted this day to come!)

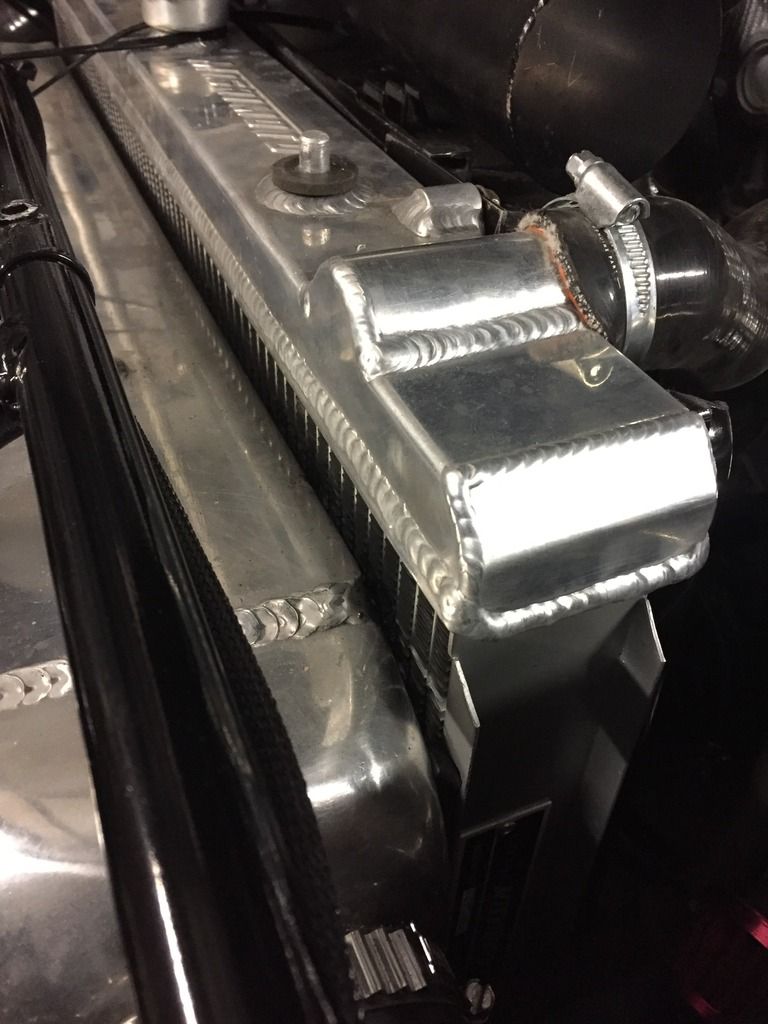

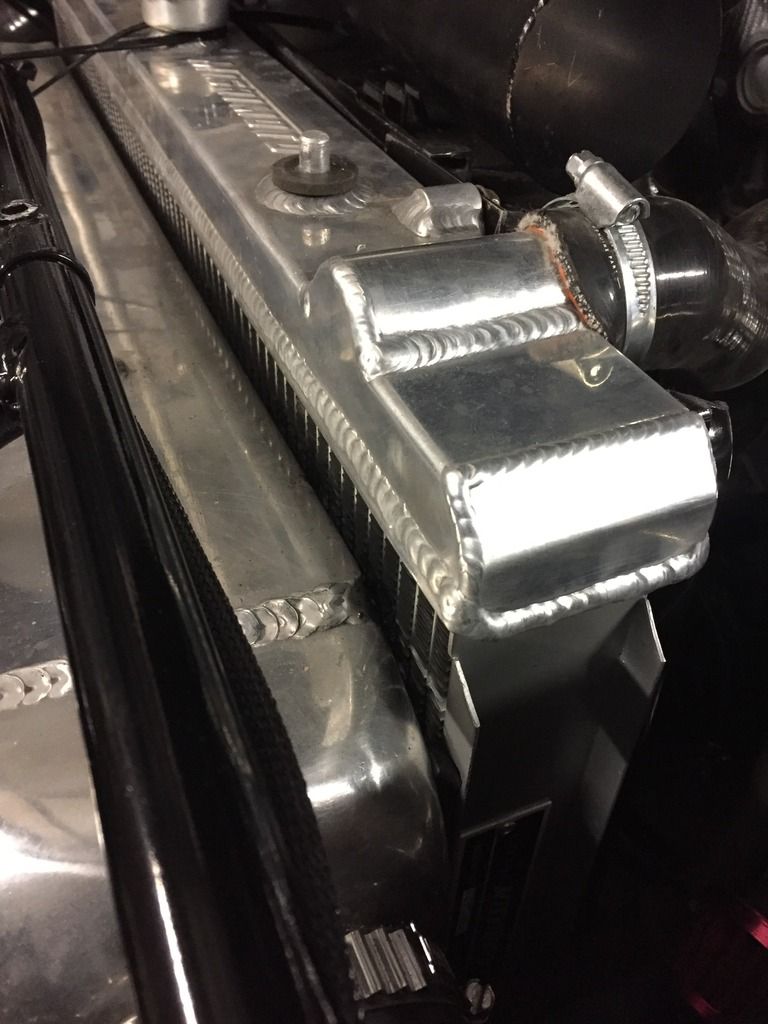

So, mapping highlighted a few areas which need to be addressed. The first being the oil leak, the 2nd was to increase the cooling efficiency of my setup. With my current setup, everything should be spot on. But, I guess with mapping the car is stationary so heat soak has an even larger effect. After a few dyno pulls, the intake temps soared. Time to get this addressed!

First things first – I’ve created a slight gap between the radiator and intercooler. My thinking here is that with these touching, the radiator is just heating the rear of the intercooler. With a slight gap thank to a thin strip of dense foam, only the very sides of one another are actually touching, which should help rectify this issue.

The intake pipe was also getting warm – again, an area where heat soak had obviously taken place due to the car being stationary. I keep thinking about reflective heat wrap and wrapping the downpipe back, but one idea was to introduce a cold air feed from the bumper to the filter – making sure the filter has a nice supply of fresh air. And if done right, would be a cool subtle addition.

In a bid to help reduce air intake temps, I’ll probably run the car without side lights for a little while. Whilst it’s a small change, it’ll introduce more fresh air to the engine bay and hopefully help lower those AIT’s!

Next up was trying to gain a bit more clearance up front as I’ve already cracked the front wing due to the front caster settings which are just random. I’ve decided to drop down to a 225/35 which should gain me that extra few mm clearance I need. Plus, it’ll also help to lower the front end.

And here’s the picture you’ve all been waiting for:

First of all – you’ll all look at the power figure and think that’s fairly low. and so did I. A TD06 at 1.4bar/20psi should be over 400hp on a strong motor! I was a bit underwhelmed/disappointed to be honest. I built the whole setup to flow and work together, so an aim of 400whp would be quite a realistic goal. As for the low power figure, we’re not entirely sure either. The way the car pulled on the dyno was nothing like a 340hp motor; it’s nothing short of savage.

The obvious theory is the dyno – as we all know, dyno’s vary from place to place. But Paul SR22 made 500hp previously, which is the power region his setup should be making. Could it have been in a wrong mode? Or was the car strapped incorrectly – as this can play with the power figures also..

The next idea was the rear alignment – with the wheels potentially pulling in different directions, could that affect the end power reading? Or the bouncy rear end – could that have meant the full power wasn’t being put down?

The motor seems to breathe nicely – it has perfect AFR’s across the entire rev range up to the 7600 rev limit. We pulled the plugs out after mapping to check them, and all of them have a super clean & equal burn.

If I remember correctly, Paul’s car made 500+hp at 74(?)% injector duty cycle – mines running 62% so it’s not a mile off. Martin did the maths – a combination of using the amount of fuel the engine is taking, and multiplying it by the amount of horsepower the SR uses (this is probably incorrect, but he did some mathematical wizardry) and said the engine is taking enough fuel for the 420hp mark. Odd! He told me to have faith that it’s 400hp setup – so the plan is to take it out on track and see just how hard it pulls!

The cool thing about the graph is how linear it is - TD06’s are notoriously “laggy”. Not on this motor

It comes on boost fast and hard, more encouraging signs it’s a strong and well built motor!

It comes on boost fast and hard, more encouraging signs it’s a strong and well built motor!The noise this thing makes is crazy. Like really crazy. Paul’s S14a was pretty damn loud, but this thing on full chat was on another level. The sound is literally to die for, it has a very angry and purposeful TD06 sound to it.

In regards to the oil leak mentioned earlier – I noticed that after the oil change it was much less frequent than before. My thoughts were now the rear crank seal, perhaps the mineral oil was too thin when warm and passing through a seal? However, there was still a slight drip when running 15w50 synthetic oil. I could either leave it be, and hope for the best. Or remove the gearbox and re-seal the area. Personally, I think the latter is the most likely option. I just don’t want to risk ruining a clutch nor an engine over a leak.

So after a really really long day – I finally made it home after battling torrential rain, Devon’s finest inclines in the dark!

- - - Updated - - -

I didn’t get home until the early hours of the morning – so set upon unloading it the following morning. What a contrasting day in terms of the weather!

Another theory was the cam timing – maybe it could have been off due to the VVT Delete – but Dave and Martin checked this after mapping to which its perfect.

My freshly built 4.08 vs my old Nismo 4.36:

- - - Updated - - -

Now mapping had finished – I could finally lower the rear end! (I really couldn’t tell you how much I wanted this day to come!)

So, mapping highlighted a few areas which need to be addressed. The first being the oil leak, the 2nd was to increase the cooling efficiency of my setup. With my current setup, everything should be spot on. But, I guess with mapping the car is stationary so heat soak has an even larger effect. After a few dyno pulls, the intake temps soared. Time to get this addressed!

First things first – I’ve created a slight gap between the radiator and intercooler. My thinking here is that with these touching, the radiator is just heating the rear of the intercooler. With a slight gap thank to a thin strip of dense foam, only the very sides of one another are actually touching, which should help rectify this issue.

The intake pipe was also getting warm – again, an area where heat soak had obviously taken place due to the car being stationary. I keep thinking about reflective heat wrap and wrapping the downpipe back, but one idea was to introduce a cold air feed from the bumper to the filter – making sure the filter has a nice supply of fresh air. And if done right, would be a cool subtle addition.

In a bid to help reduce air intake temps, I’ll probably run the car without side lights for a little while. Whilst it’s a small change, it’ll introduce more fresh air to the engine bay and hopefully help lower those AIT’s!

Next up was trying to gain a bit more clearance up front as I’ve already cracked the front wing due to the front caster settings which are just random. I’ve decided to drop down to a 225/35 which should gain me that extra few mm clearance I need. Plus, it’ll also help to lower the front end.

200sx_

PS13 x TD Power

Whilst I was going to setup the front suspension, one area I wanted to change was the tie rod length. I could’ve gotten a friend to cut and sleeve them to create additional length, but I’m a huge fan of bolt on items. Mainly because if I bend a tie rod at the track, I can easily replace them. I noticed GKTech do a new tie rod with A LOT of thread, where you simply cut it to the desired length, so I grabbed myself a couple.

Tein Rods & Non-Offset Rack Spacers vs New GKTech Tie Rods

- - - Updated - - -

Before I fit the above, I decided to quickly fit the new diff and bed it in. Although the Super Q diff doesn’t need to be bedded in due to special coating on the plates, I thought it’d be best practice to do so just to make sure everything is working 100%. It was the first time driving this chassis, and it was just jaw dropping in all honestly. Even though it was low speed, it felt responsive in both the engine and the chassis. The hunger to get this thing out on track grew even more!

Jesse Streeter hooked me up with another pair of fresh front wings. I’ll paint these and keep them as a spare set. I feel like the current pair of wings will be sacrificed during the setup on the car to find that sweet spot – where I can run the car low, and run a setup where it handles like I want it to.

- - - Updated - - -

Aaaaand up the car goes back to it’s natural habitat!

So that’s the car kinda of up to date (for now!). Over the Christmas break I’ll hopefully be removing the gearbox so I can fix this damn leak whilst I complete a few other jobs. If all goes well, I want to do a grip day first to shake the car down and then see about going sideways. I literally cannot wait!

Tein Rods & Non-Offset Rack Spacers vs New GKTech Tie Rods

- - - Updated - - -

Before I fit the above, I decided to quickly fit the new diff and bed it in. Although the Super Q diff doesn’t need to be bedded in due to special coating on the plates, I thought it’d be best practice to do so just to make sure everything is working 100%. It was the first time driving this chassis, and it was just jaw dropping in all honestly. Even though it was low speed, it felt responsive in both the engine and the chassis. The hunger to get this thing out on track grew even more!

Jesse Streeter hooked me up with another pair of fresh front wings. I’ll paint these and keep them as a spare set. I feel like the current pair of wings will be sacrificed during the setup on the car to find that sweet spot – where I can run the car low, and run a setup where it handles like I want it to.

- - - Updated - - -

Aaaaand up the car goes back to it’s natural habitat!

So that’s the car kinda of up to date (for now!). Over the Christmas break I’ll hopefully be removing the gearbox so I can fix this damn leak whilst I complete a few other jobs. If all goes well, I want to do a grip day first to shake the car down and then see about going sideways. I literally cannot wait!

200sx_

PS13 x TD Power

Thanks for the comments guys!

So I spent a little time with the car today - nothing drastic but I wanted to fit a cold air feed to the filter to help lower intake temps. So first things first, with the UK being pretty damn cold right now, I fuelled this thing up. if you don't have one, and your fed up of being cold, buy one! I literally love this thing!

I've seen a few different way to run this stye of piping, with the majority opting to just hang it out of the bumper. It may do the job, but c'mon - that's not very neat now..

After seeing where the end needs to be, I set about creating a small aluminium strip which utilises an existing bolt hole. I chose an aluminium strip and it doesn't need to be really strong, just enough to hold in place should the bumper decided to say bye bye. After a bit of trial and error, here's the outcome:

I'm yet to position the top of the hose, but the idea will be simple - sit a an inch or two below the air filter and pointing in the general direction. I feel once the car is moving, heat soak should be nowhere near as bad as a dyno, where the air flow is pretty much static. But i'll carry on with some ducting to the intercooler and cooler AIT's/efficient setup can never be a bad thing!

Here's how the feed sits in the bumper:

I like it. It look's purposeful and subtle. I could've opted for a bright colour or to have it hanging out the bumper, but I'm happy with the way it looks now.

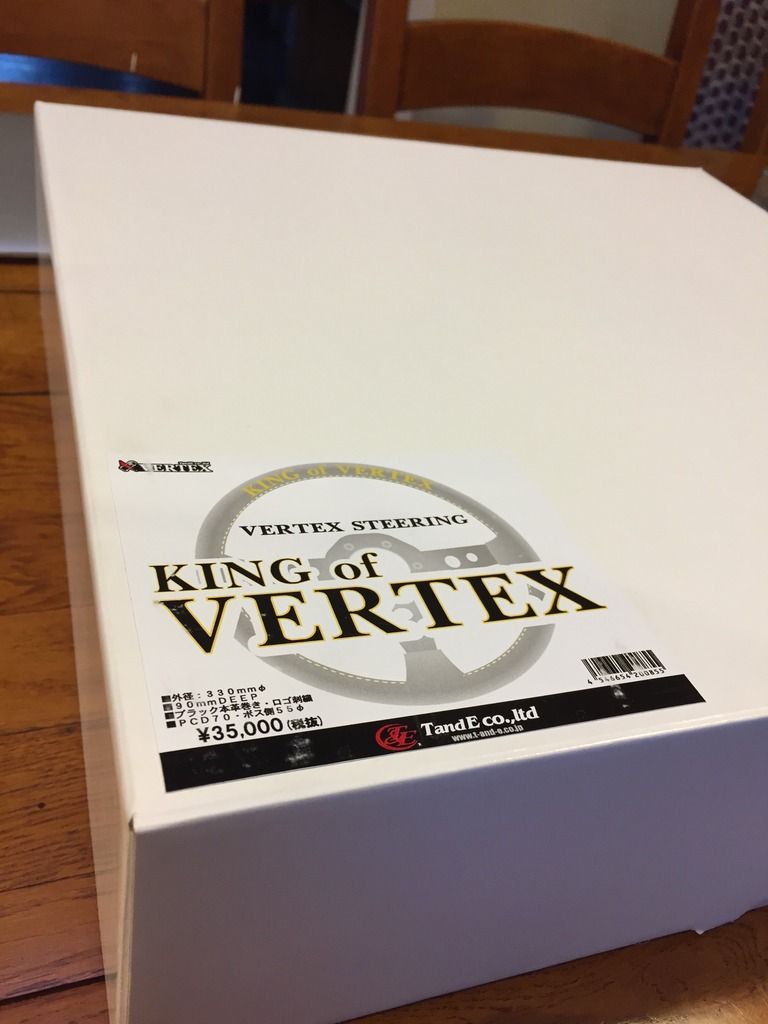

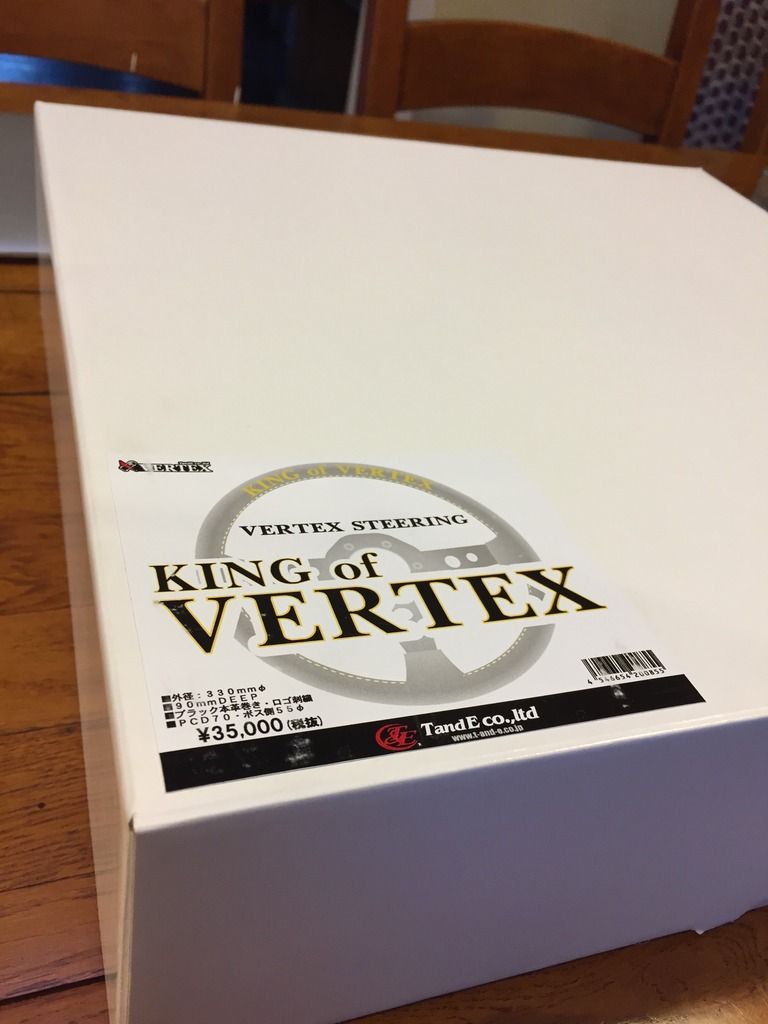

I received a package in the post today. I've been after one of these for a while now, and almost bought one through Jesse Streeter until I saw Driftworks have become the European distributor for Vertex T&E. The guys at Driftworks hit me up with an awesome deal, so a purchase had to be made. I'll the let the pictures do the talking, although they really don't do the steering wheel any justice!

The quality is outstanding, literally the best wheel i've ever laid eyes or hands on! It's subtle and classy When I get a chance i'll fit the wheel to the Works Bell snap off boss, which should result in one hell of a combination!

When I get a chance i'll fit the wheel to the Works Bell snap off boss, which should result in one hell of a combination!

So I spent a little time with the car today - nothing drastic but I wanted to fit a cold air feed to the filter to help lower intake temps. So first things first, with the UK being pretty damn cold right now, I fuelled this thing up. if you don't have one, and your fed up of being cold, buy one! I literally love this thing!

I've seen a few different way to run this stye of piping, with the majority opting to just hang it out of the bumper. It may do the job, but c'mon - that's not very neat now..

After seeing where the end needs to be, I set about creating a small aluminium strip which utilises an existing bolt hole. I chose an aluminium strip and it doesn't need to be really strong, just enough to hold in place should the bumper decided to say bye bye. After a bit of trial and error, here's the outcome:

I'm yet to position the top of the hose, but the idea will be simple - sit a an inch or two below the air filter and pointing in the general direction. I feel once the car is moving, heat soak should be nowhere near as bad as a dyno, where the air flow is pretty much static. But i'll carry on with some ducting to the intercooler and cooler AIT's/efficient setup can never be a bad thing!

Here's how the feed sits in the bumper:

I like it. It look's purposeful and subtle. I could've opted for a bright colour or to have it hanging out the bumper, but I'm happy with the way it looks now.

I received a package in the post today. I've been after one of these for a while now, and almost bought one through Jesse Streeter until I saw Driftworks have become the European distributor for Vertex T&E. The guys at Driftworks hit me up with an awesome deal, so a purchase had to be made. I'll the let the pictures do the talking, although they really don't do the steering wheel any justice!

The quality is outstanding, literally the best wheel i've ever laid eyes or hands on! It's subtle and classy

When I get a chance i'll fit the wheel to the Works Bell snap off boss, which should result in one hell of a combination!

When I get a chance i'll fit the wheel to the Works Bell snap off boss, which should result in one hell of a combination!