So I think it’s about time to do an update?!

---------------------------------------

Shortly after the last post, it was time to stop procrastinating and drop the Z33 gearbox and find out what this leak was.

Removing the gearbox is like any other, remove the prop, shifter, cross member and the bolts. The latter can be a bit tricky though! The bottom/side bolts aren’t too bad with the correct tools, but the top ones… those are a pain in the backside! Nevertheless, after a bit of persevering me and a friend managed to undo them. I can see why people may want to enlarge the firewall, purely for this matter but it’s definitely not a necessity. Once all of the bolts where undone, it took us probably about 15 seconds to physically remove the box!

About here I’ve got to say most of the credit for the box removal has to go to a friend as he sacrificed his Friday evening to help remove a gearbox. As you could imagine, we were pretty impressed how fast the box came out, after all – it is a large gearbox in a small tunnel! I can only assume this is because you can remove the shifter, so there is no need to rotate and jiggle the box. In all, it took us 2 hours to remove the box from start to finish, not bad in my opinion!

Voila! – 1x Z33 Gearbox removed. Now it was time to see what was leaking. First inspections was that the bellhousing was essentially bone-dry. Which kind of put my mind as ease it means the box has sealed up perfectly fine. However, this is also means the leak is from the engine.

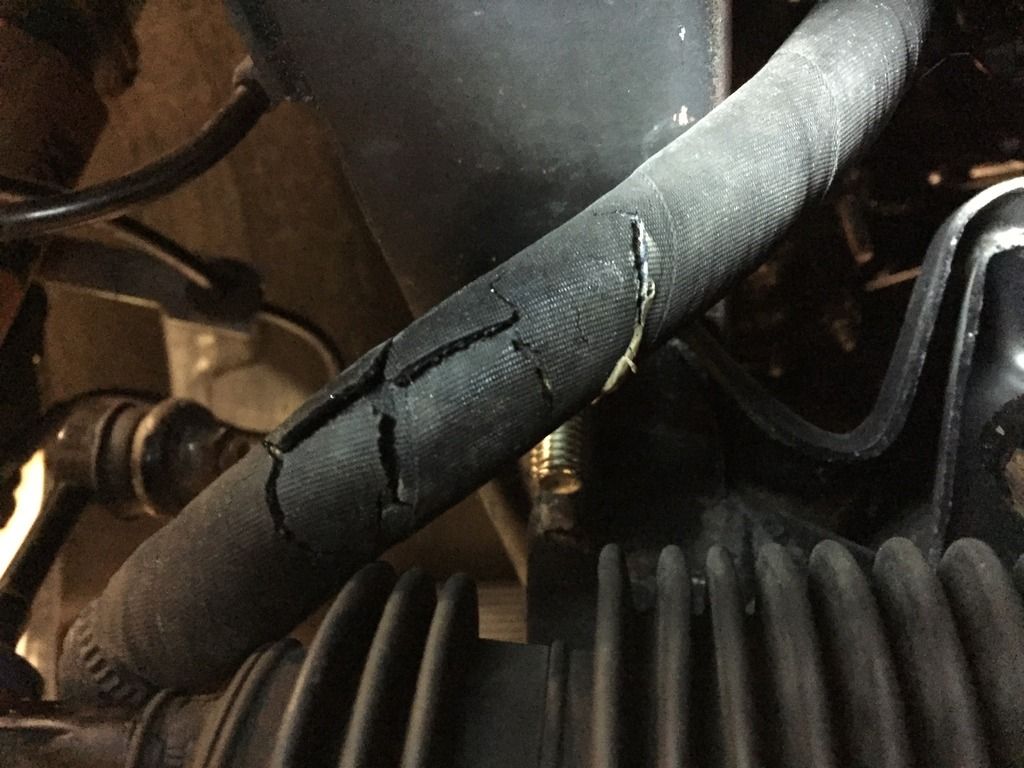

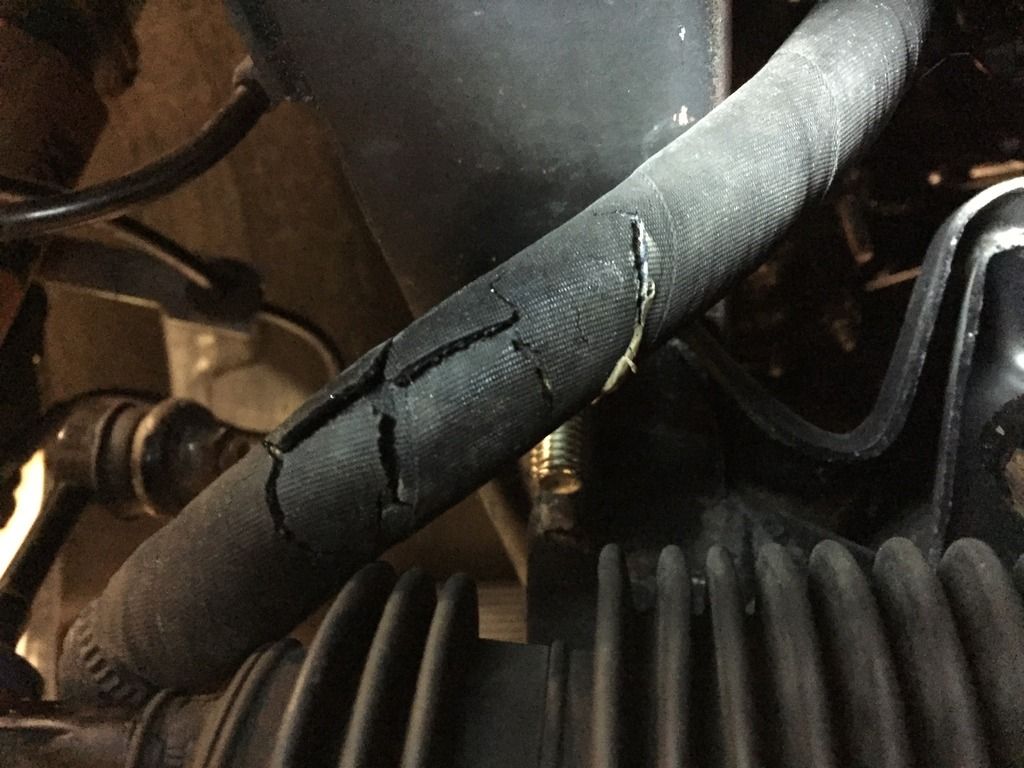

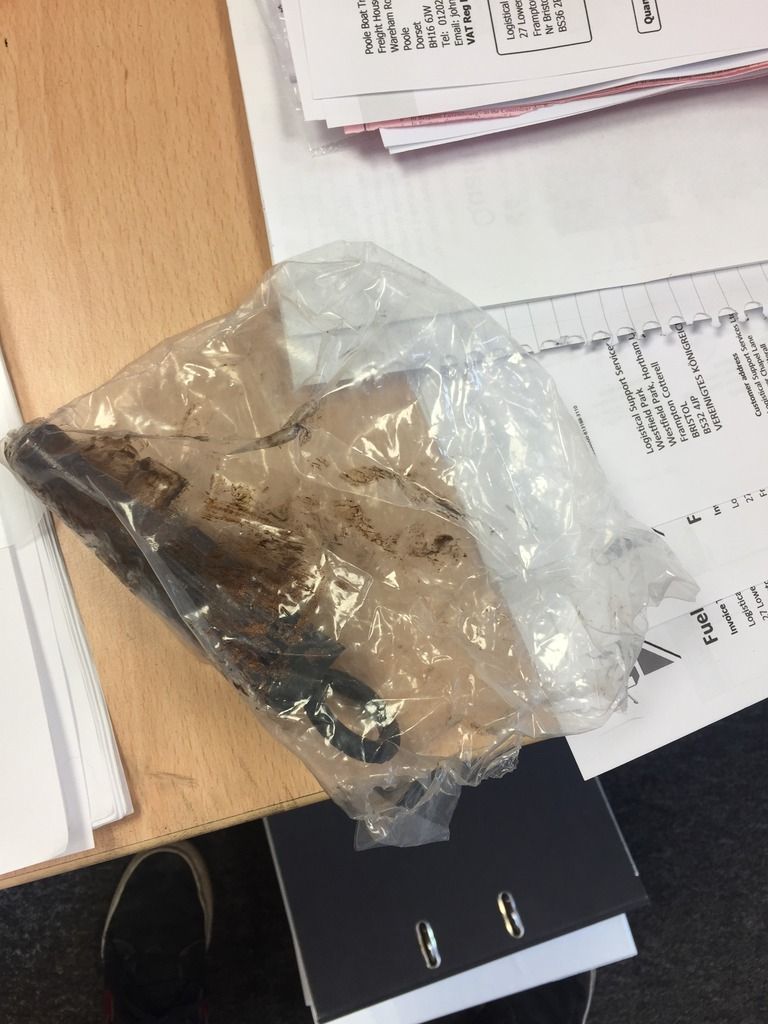

Whilst I was under the car, I managed to see the state of my turbo oil drain/return. I always sknew it sat close to the manifold/runner due to the inherent design of the Mid-Mount, but unfortunately it was rubbing on the dyno. Which, when you think about it, MB was getting that manifold glowing – a pretty scary thought! Here’s the damage:

Luckily enough the outer skin of the hose essentially had peeled away under the extreme heat, but didn’t cause any long term damage. If that hose had burned through, then it would’ve meant a fire or terminal damage for sure. Not good!

Back to the drawing board I go – back to my first idea actually. Initially I wanted to convert the oil drain fitting in the block to an AN10 one, so now is the time to do it. Reason being is because of an angular fitting, where I should be able to gain some more clearance over the standard barbed fitting.

Back onto Torques’ web shop I went and spent yet more money on AN fittings!

I struggled like hell to remove the standard fitting (after all, it had been in there for 20 years or so!) So my friend came to the rescues yet again, and before we knew it the AN10 fitting was installed.

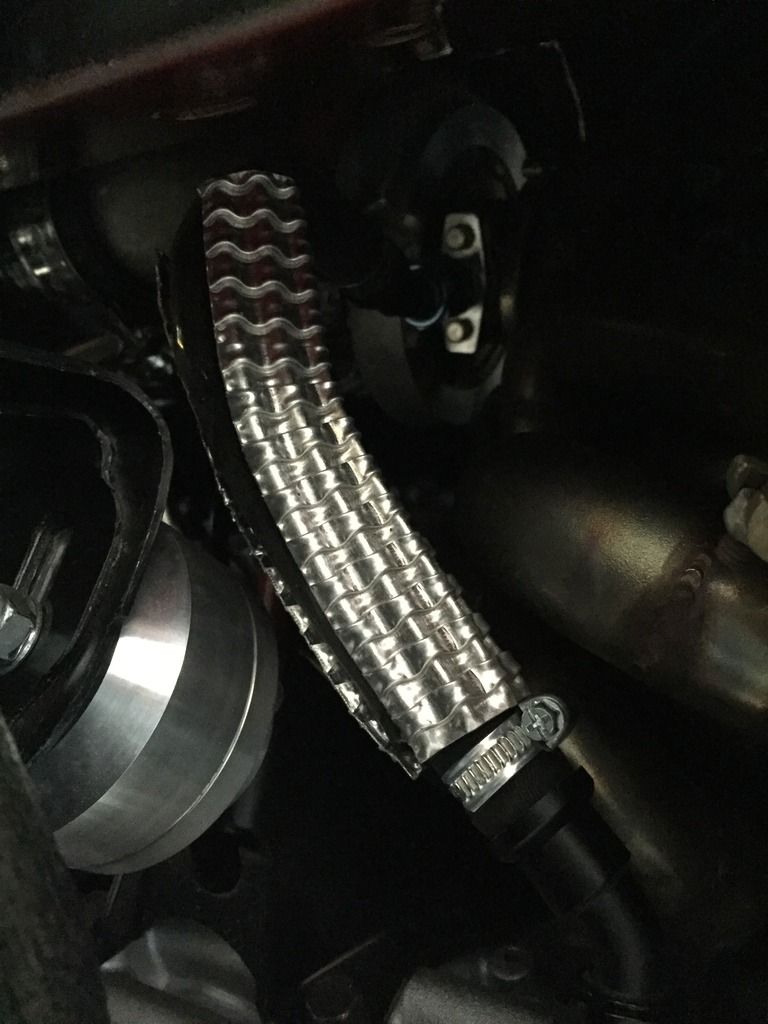

After looking at the angles involved, I went with a 45* fitting hoping it’d gain me the clearance I wanted, and it did! OK, it’s not lots and lots of clearance, but there’s an air gap and the rubber won’t be touching the runner.

After a bit of trial and error, I had a new oil drain made up

With a slightly longer hose, I was able to initially point the drain away from the manifold at the turbo, helping to create a long sweeping bend without any major kinks.

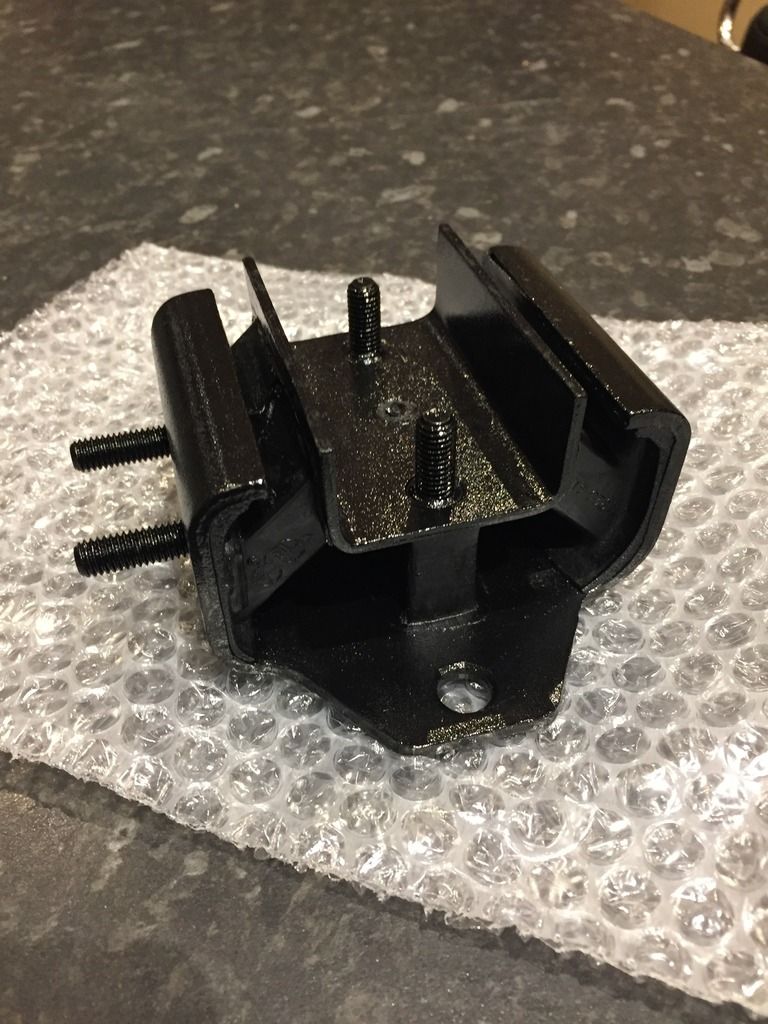

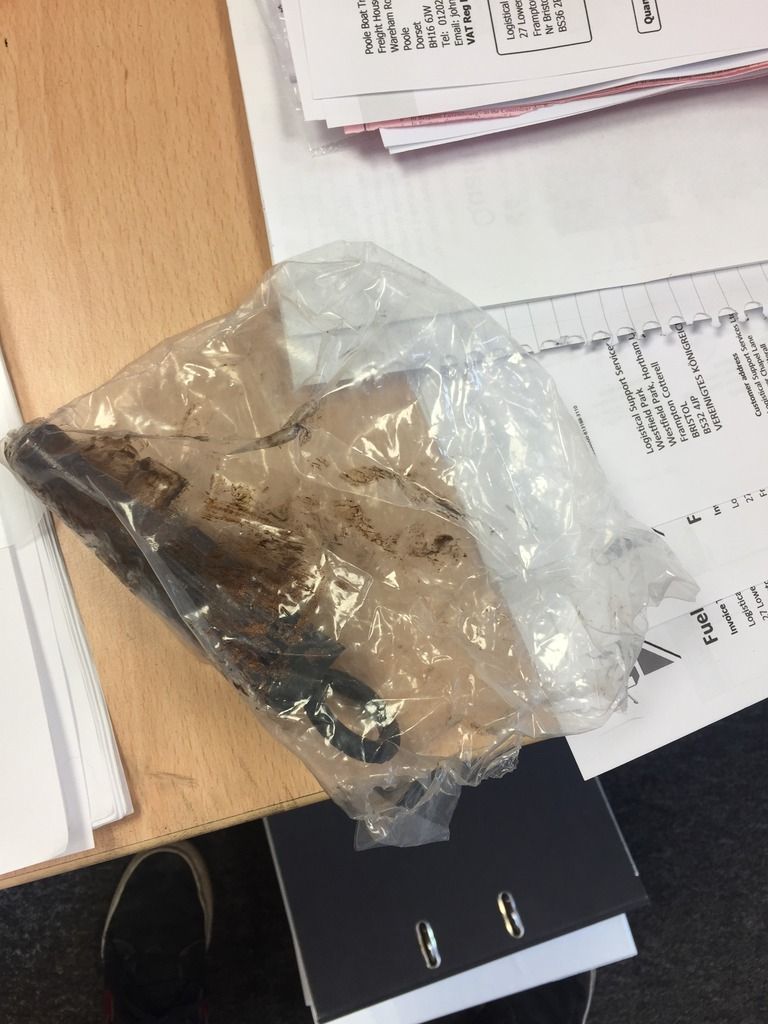

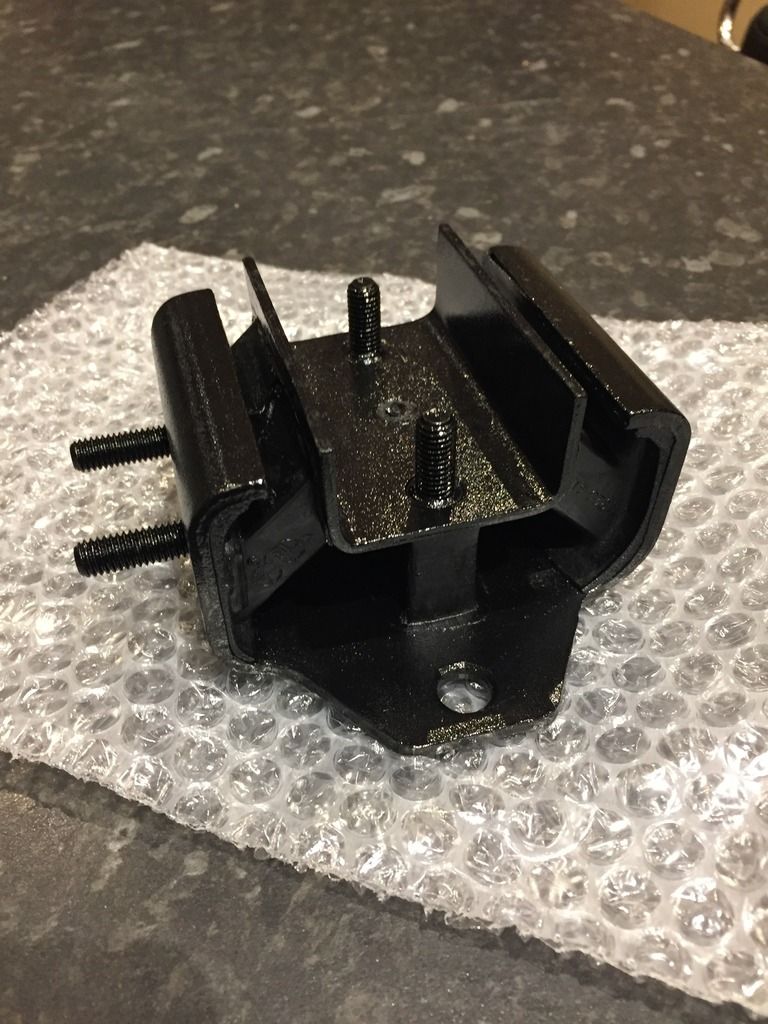

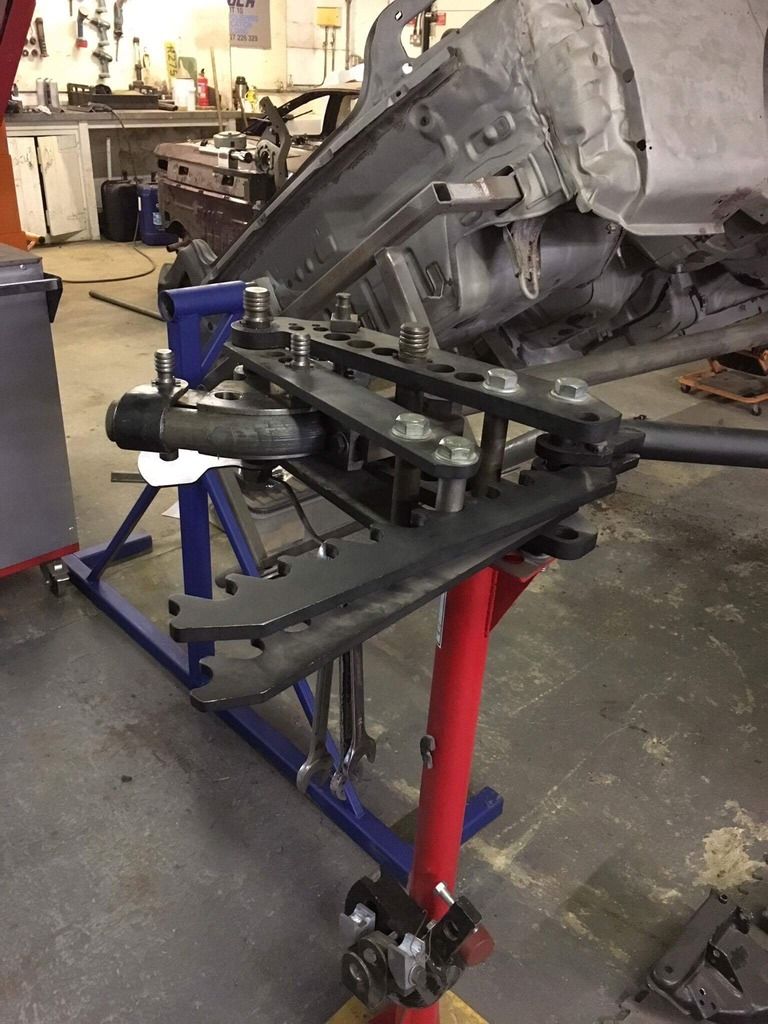

Whilst the gearbox was off, there was one thing I wanted to change. I’ve never been happy with the gearbox mount as it was an OEM item, which isn’t the stiffest, and given the boxes additional weight, I can’t imagine it’d be doing itself any favours. I considered getting the Nismo gearbox mount, but went with the Apex/Hardrace item as it worked out quite a bit cheaper for something that some may consider a superior item. I opted for the Race version, as I don’t really want the gearbox to be moving around. Plus, it means the gearbox mount should be equally matched to my engine mounts.

Plus some fresh hardware as the first set of washer were too thin and bent under the pressure of torqueing the nuts.

- - - Updated - - -

- - - Updated - - -

Anyway – back to the mysterious oil leak. I can’t remember if I mentioned it previously, but I suspected the oil leak to be the rear crankshaft seal. Mainly due to the way the leak behaved. During running in, the leak was quite prominent, but seemed to reduce when running a thicker synthetic oil.

Once the box was off, I had a quite look and saw traces of oil on the rear crankshaft seal and the surrounding area. BINGO – leak identified. I gave Dave @ DY Engines a quick text to let him know where the leak was and before I knew it he had ordered another seal through Nissan!

Dave being Dave, popped up as soon as he was free and changed the seal over for me. Some people claim certain people build the best engines because of this and that, but Dave is a guy who is passionate in his work (I mean, this motor performed flawlessly on the dyno during the run in procedure and mapping, both of which were straight after eachother). He changed the seal out of his own pocket and time, I honestly cannot fault him for that!

The most likely reason for the seal to leak was the fact the motor had been sat up for quite a while between getting built and fired up. Seals can dry out, and with the rear crank seal, we think it dried up ever so slightly and burned out when the motor was first fired up. All seems to have been cured now, but we wont know until the motor sees some load on the track.

Once Dave swapped out the rear seal, he also kindly put my flywheel back on for me. But the one tool I don’t own is a clutch alignment tool. My clutch never came with one, but alas Dave came to the rescue again and sent me one up.

My friend popped back over to give me a hand putting the box back on, so the first thing to do was align the clutch plates:

It took us about another hour/hour and a half to put the box back on with all the bolts and associated parts (prop, shifter, gearbox oil etc). Once everything was back together with some fresh engine oil, we fired it up and everything seemed perfect. (The cynic inside me says things are never perfect) But the box seems happy, engages all the gears with no sign of any oil leak.

)

)