Sidewayzz

Member

Hey everyone, My name is Chris or some of you may know me as @Sidewayzz of Instagram. I've decided to make a build thread for my 2nd S14 Silvia. Before I begin I’ll explain what happened to the first one.

In March of last year I attended a track day, and during my 3rd or 4th outing the car suddenly 360 spun into the wall around the hair pin causing significant front and rear damage as you would expect hitting a concrete barrier. Luckily passenger and I were fine but the car was a bit worse for wear.

We towed it home and got straight into stripping it apart later that day to assess the damage. Taking off the bent panels one by one the car didn't look as bad but we later discovered that the chassis rail had bent front and rear.

My second worry was that my engine that I just had spent all this time and money on would be wrecked from the crash but everything seemed fine apart from a few bent Intercooler pipes.

I sourced a cheap Intercooler and piping off Trade Me and installed it to see if it still turned over. I checked all the fluids everything was ok so I turned it over thinking the worst, it started first pop and that was a big sigh of relief. I started getting a few quotes from local panel beaters but the price was way too much and sourcing a new shell and swapping everything over was the best option.

A very sad sight and it still hurts to this day but onwards and upwards right guys?

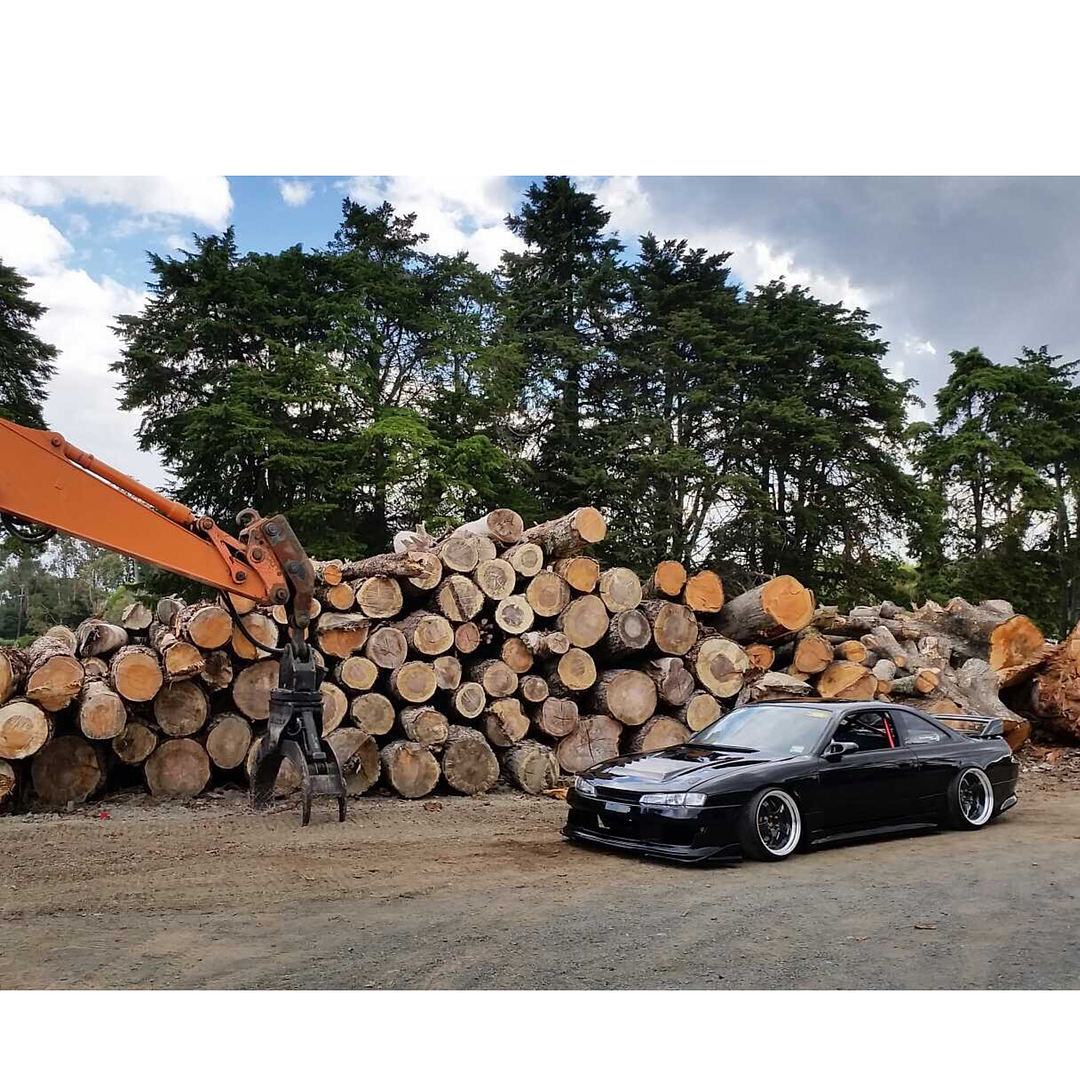

Months flew by of searching for a s14 facelift body and nothing, I was determined to get another S14 so I started gathering bits I needed for the re shell. 5 months later I saw a black s14 pop up for sale and organised to go view it the next day. I went to view it and it was everything I wanted, clean and un molested. The car was a SR20DE and auto but I wasn't too fussed as I had my SR20DET engine and manual setup out of the other car. A deal was made and I picked it up the next day.

I drove it home with a annoyingly loud fart cannon of an exhaust complete with edaboc stickers on the rear window. I got home and took off the stickers and removed the fart cannon exhaust and swapped it for the factory item the previous owner gave me.

I think the previous owner tried to tuck this exhaust against the subframe. Very weird..

I continued to drive it as is for around 5 weeks while saving money and planning what I was going to do with this new car. I started by contacting Alex from Moonlight Racing and ordered an Origin Lab Stylish Body kit and 20mm front fenders.

I moved the wrecked S14 to the yard to I could start to dis assemble it.

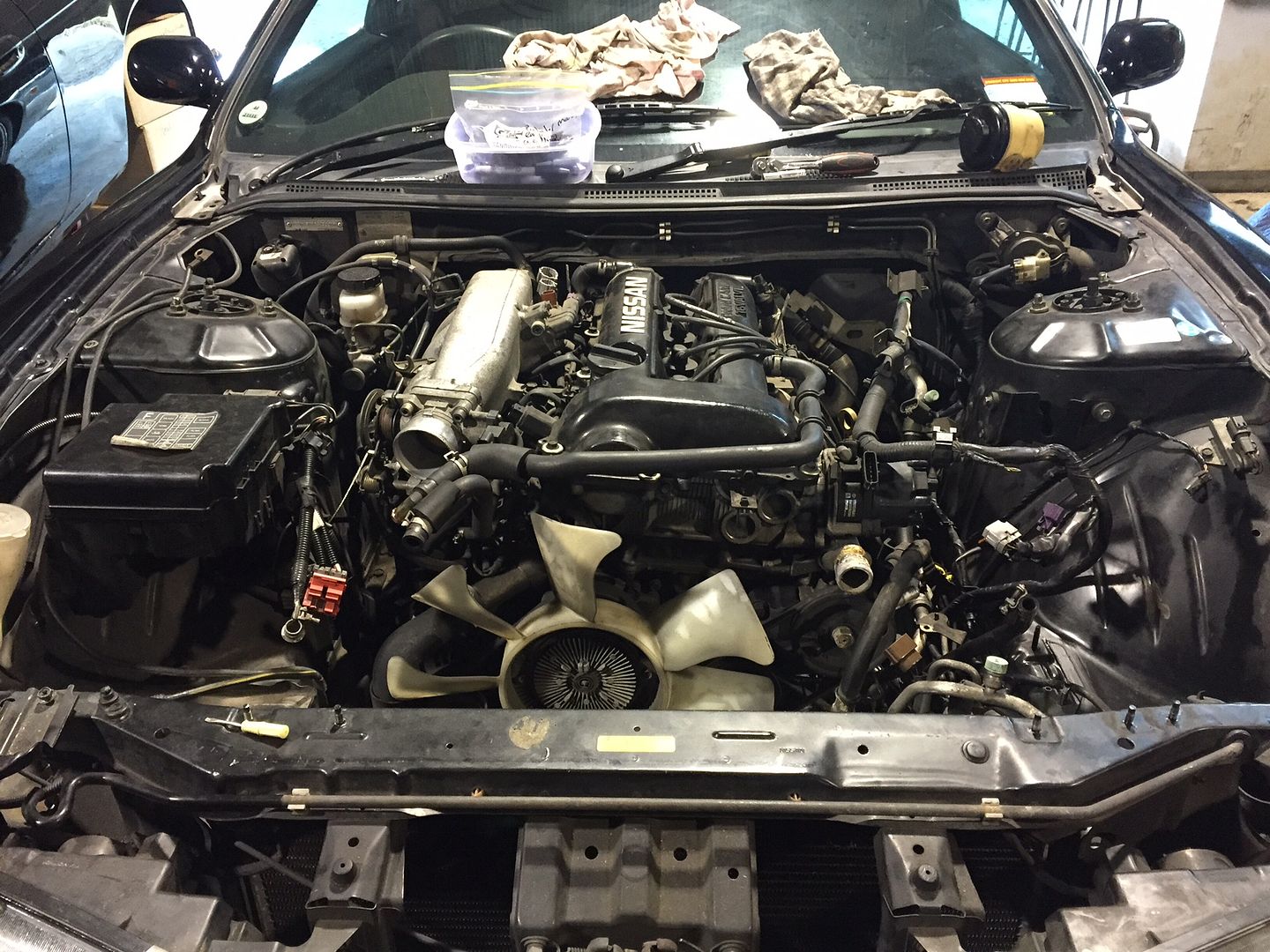

I started with the engine and gearbox

First I drained all the fluids and removed all intercooler piping and radiator. Next was to disconnect all the wiring and hoses connected to the engine etc..

Next it was time to strap the engine up and remove the engine mount bolts, support the gearbox with a jack and remove the gearbox cross member. Then we slowly started to lift the engine and gearbox out checking for anything connected to the engine. Everything was free and out it came

The next day I took off the bell housing bolts to remove gearbox as I was selling it because I'll be upgrading, and to check out the condition of the flywheel and clutch.

This is what the clutch looks like. Pretty toast right? I'll be replacing this with a new item but am un decided on what one at the moment.

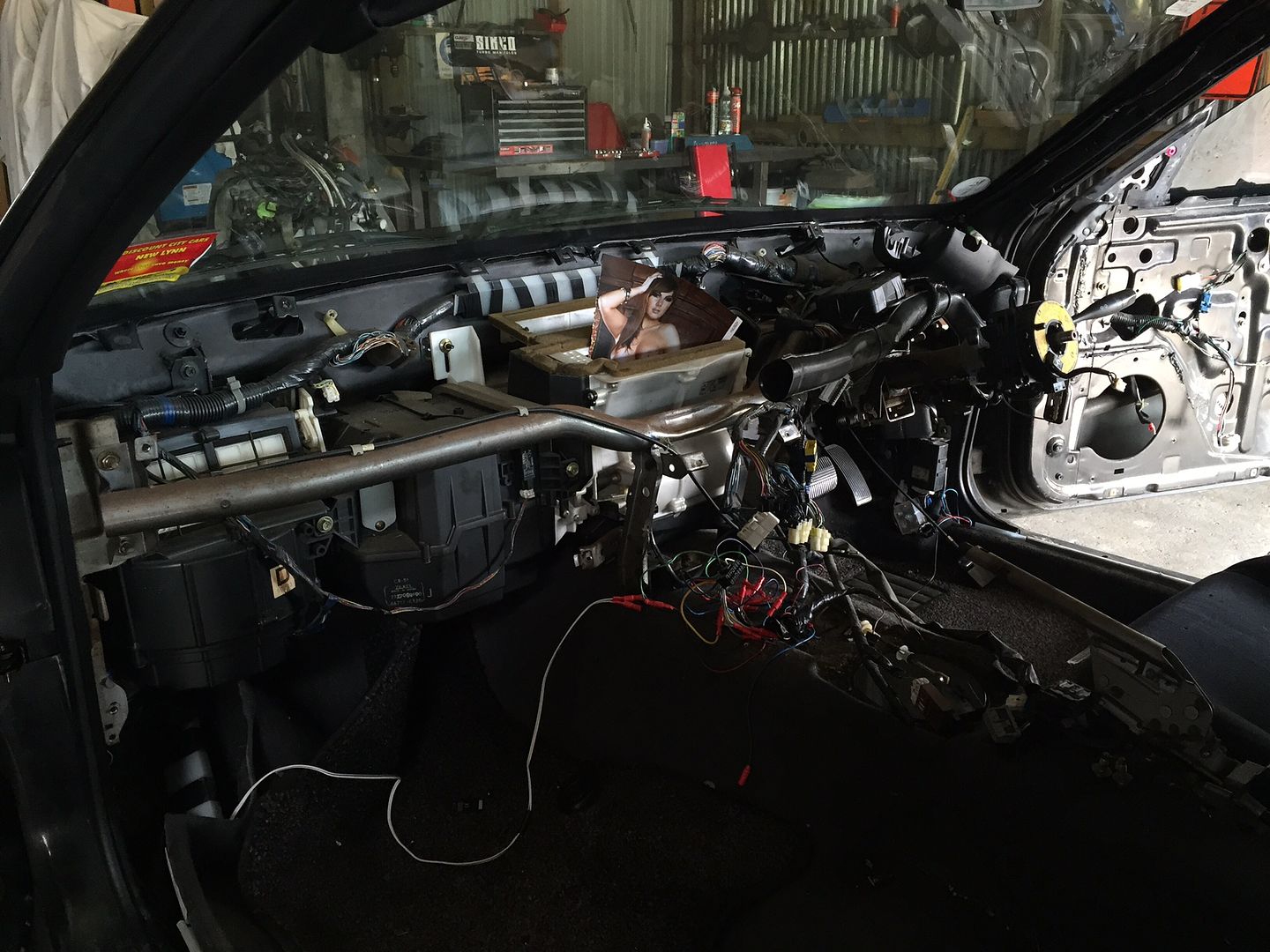

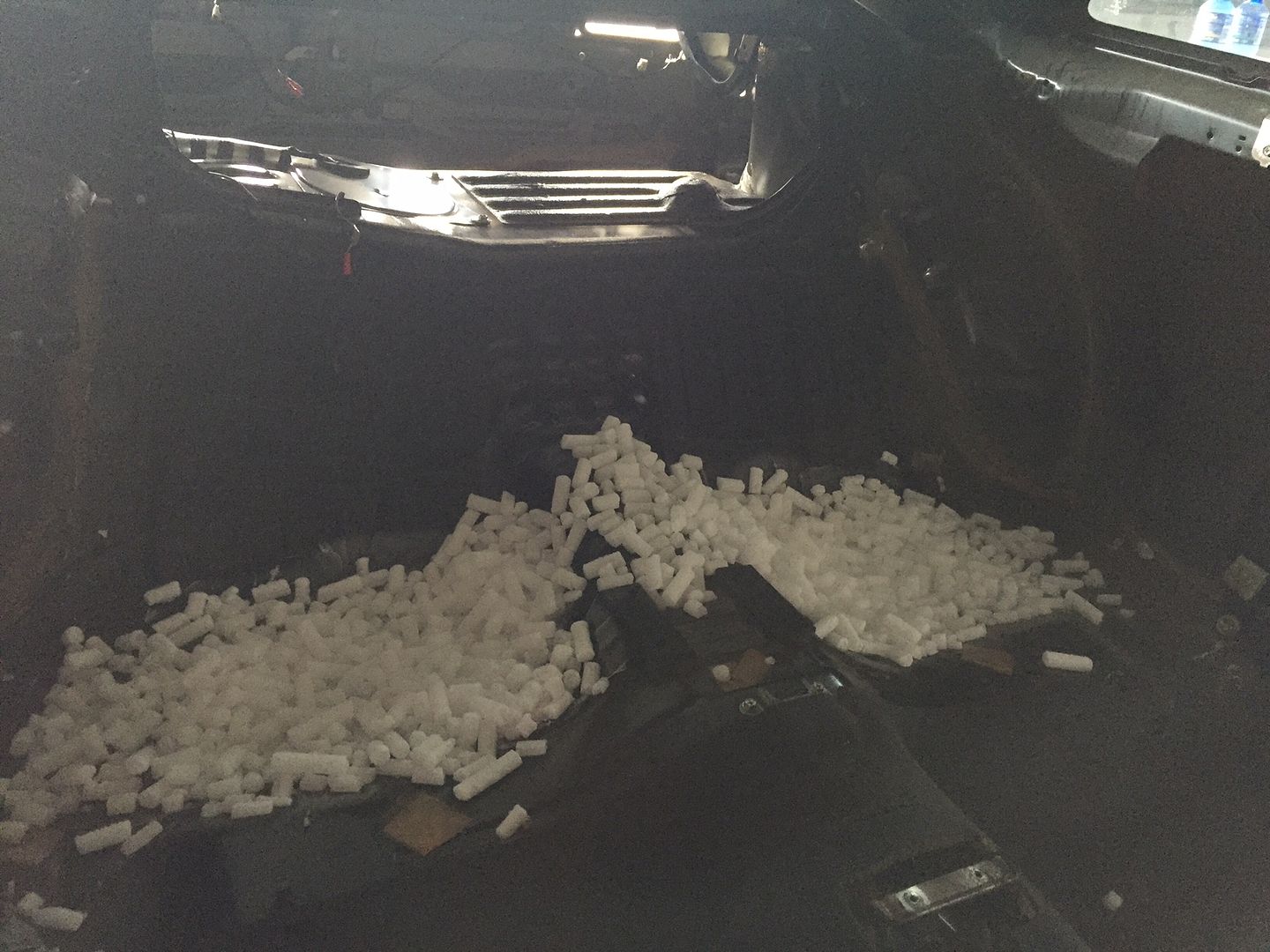

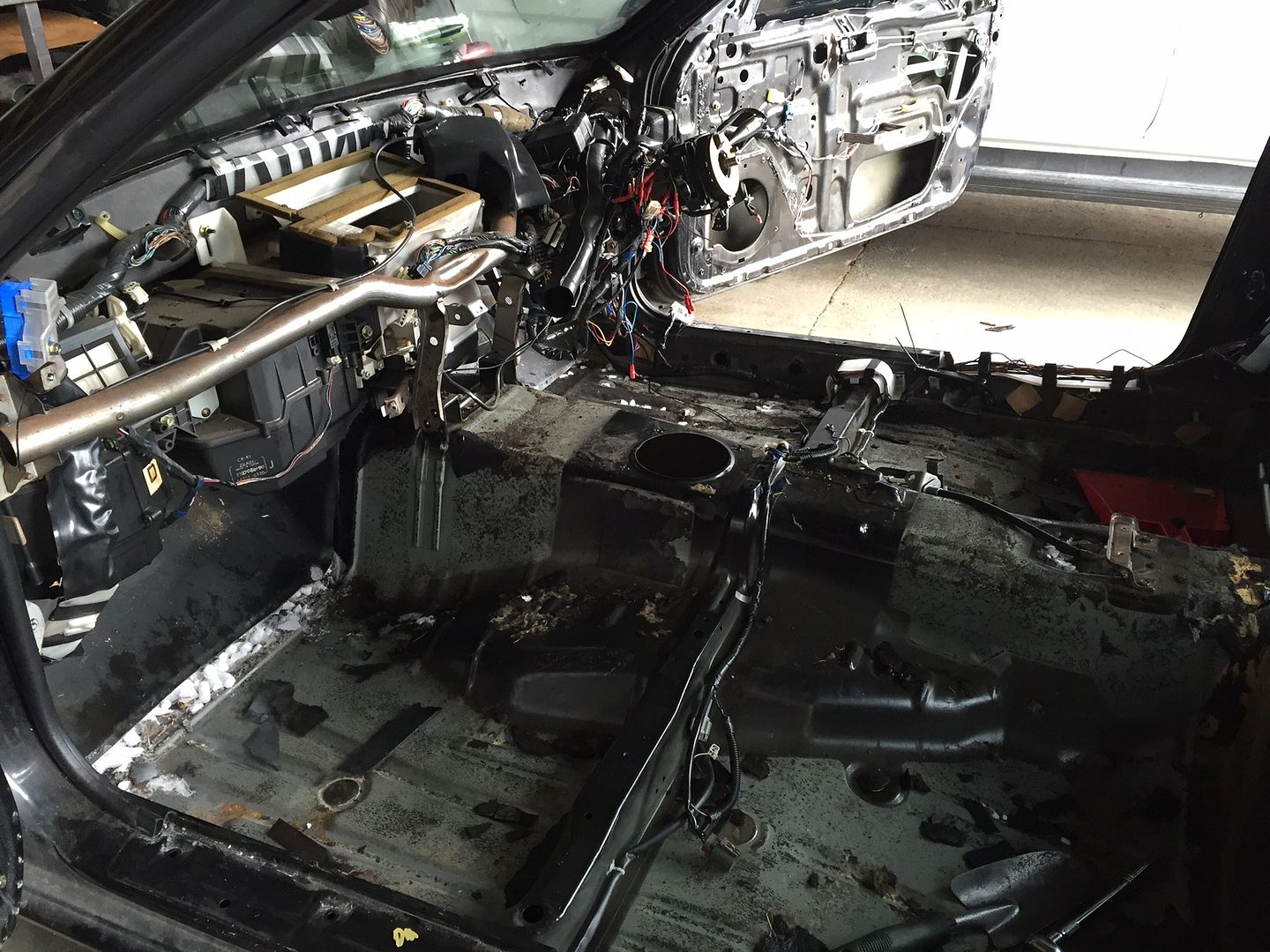

Next to come out was the dash, centre console, door trims, centre climate control, steering wheel, quick release, ecu etc.. Everything inside came out so I could swap it all over

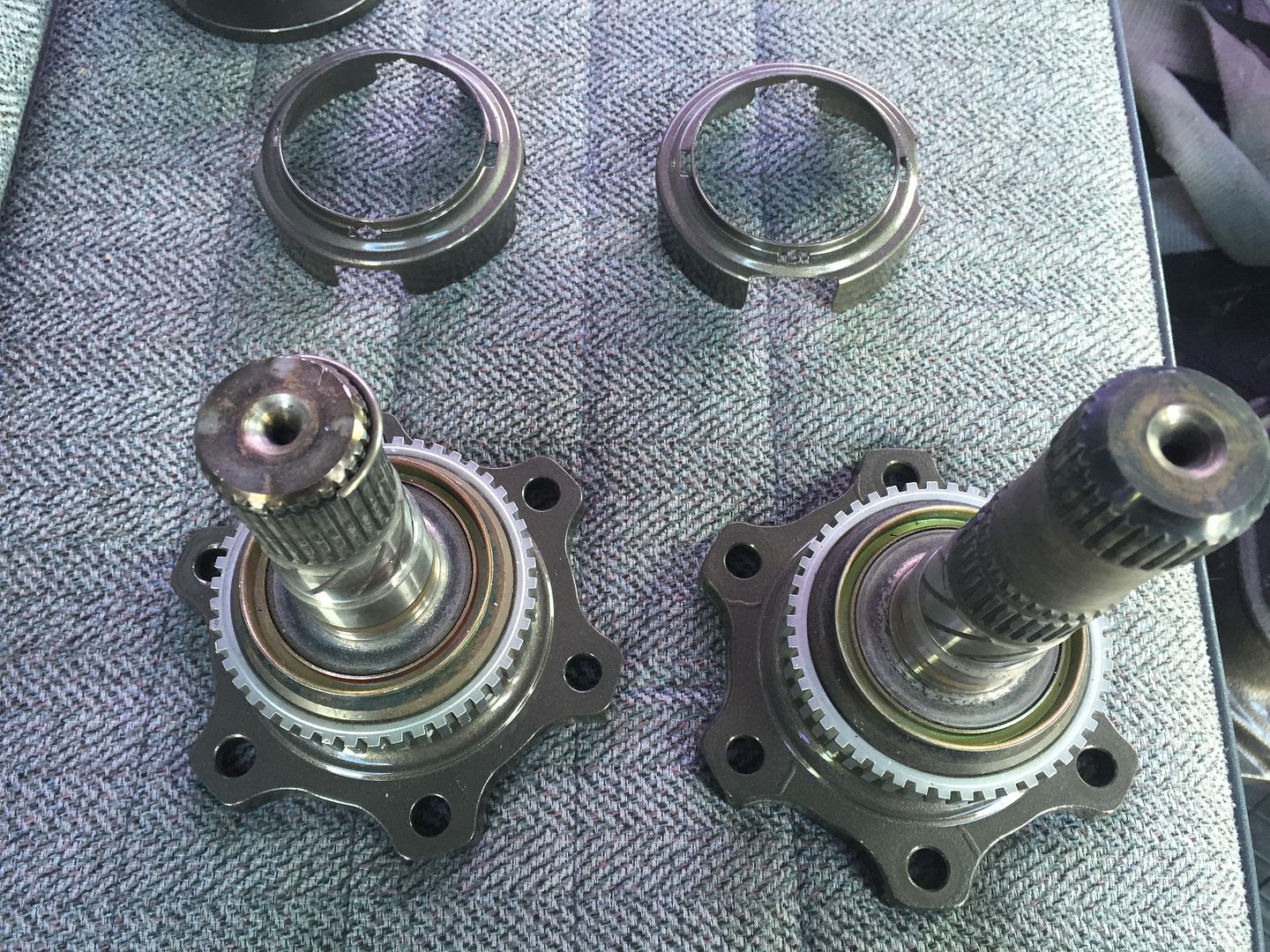

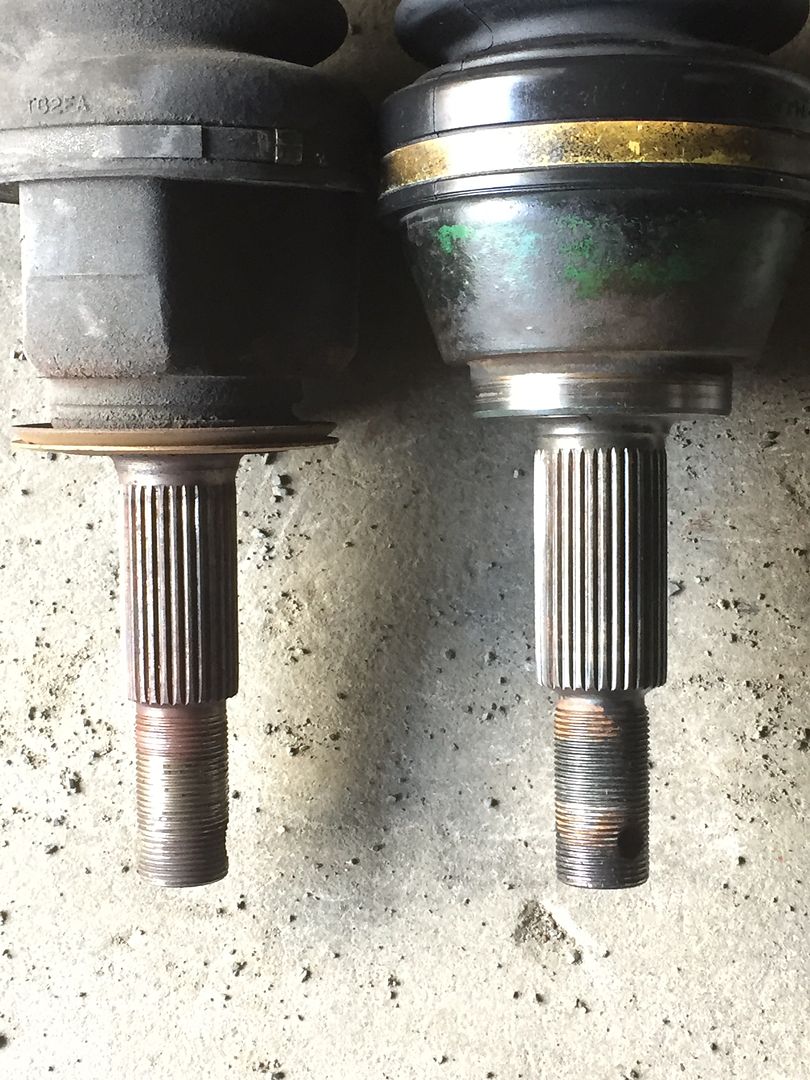

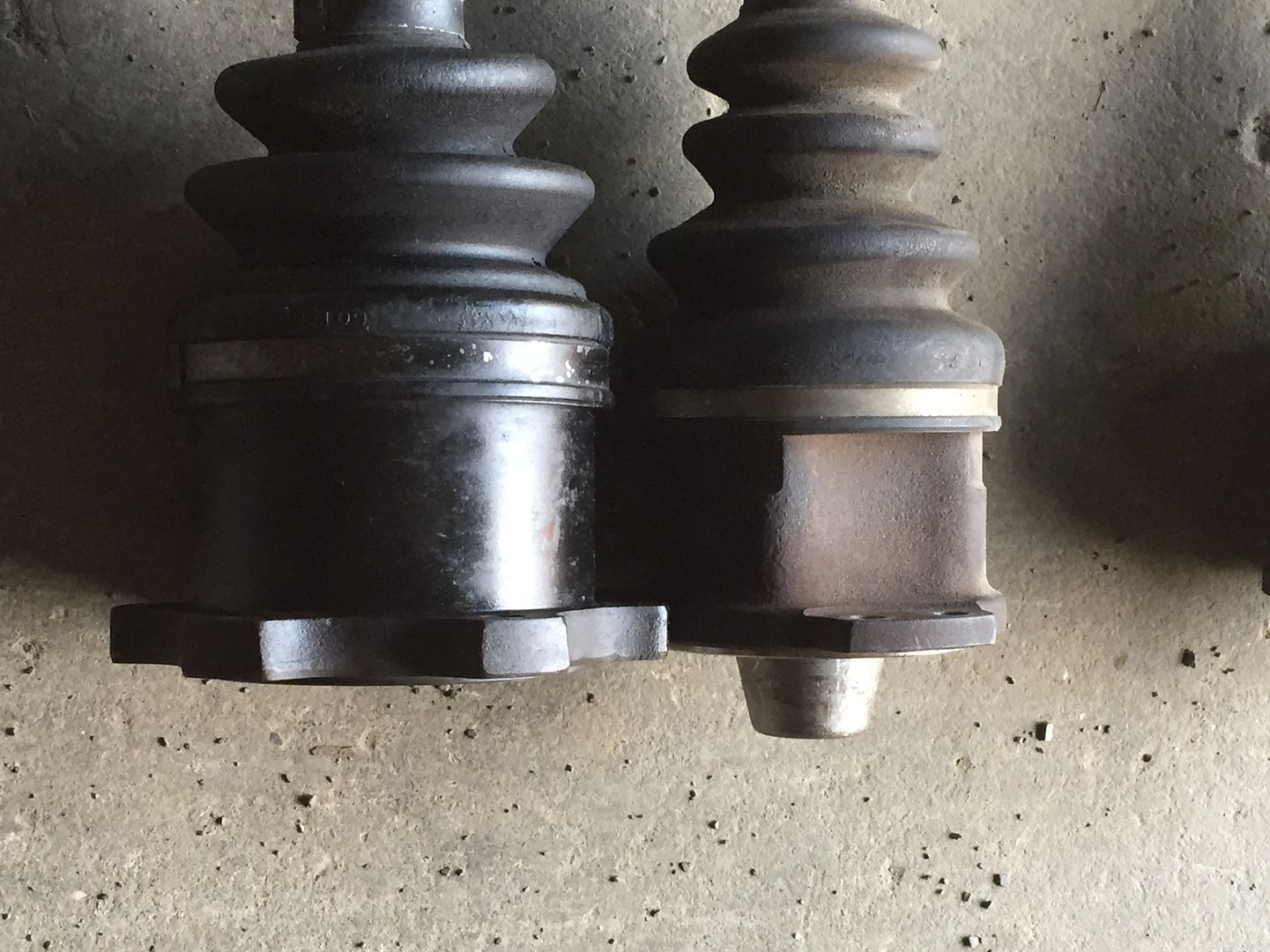

Onto the subframe next, the driveshaft was already removed so it was simply removing calipers and tie them out of the way, undo the lower coilover bolt, remove handbrake cable brackets, support the subframe with the jack and undo the bolts holding the subframe and slowly lowering it down with the jack.

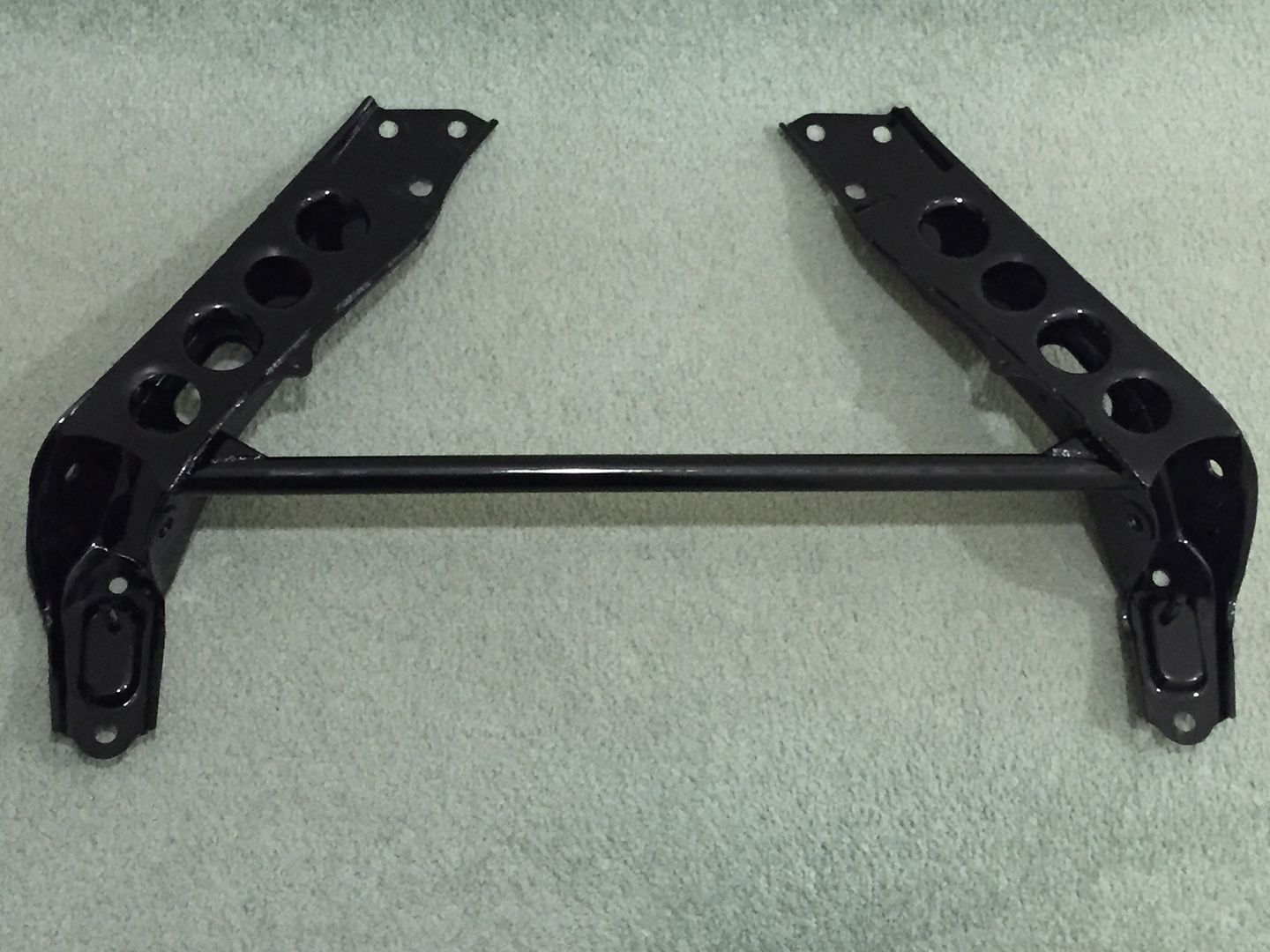

Next was removing the whole front crossmember including brakes/ rotors/ suspension

I scavenged a few more things from it and at this stage it was a stripped shell sitting on stands.

In March of last year I attended a track day, and during my 3rd or 4th outing the car suddenly 360 spun into the wall around the hair pin causing significant front and rear damage as you would expect hitting a concrete barrier. Luckily passenger and I were fine but the car was a bit worse for wear.

We towed it home and got straight into stripping it apart later that day to assess the damage. Taking off the bent panels one by one the car didn't look as bad but we later discovered that the chassis rail had bent front and rear.

My second worry was that my engine that I just had spent all this time and money on would be wrecked from the crash but everything seemed fine apart from a few bent Intercooler pipes.

I sourced a cheap Intercooler and piping off Trade Me and installed it to see if it still turned over. I checked all the fluids everything was ok so I turned it over thinking the worst, it started first pop and that was a big sigh of relief. I started getting a few quotes from local panel beaters but the price was way too much and sourcing a new shell and swapping everything over was the best option.

A very sad sight and it still hurts to this day but onwards and upwards right guys?

Months flew by of searching for a s14 facelift body and nothing, I was determined to get another S14 so I started gathering bits I needed for the re shell. 5 months later I saw a black s14 pop up for sale and organised to go view it the next day. I went to view it and it was everything I wanted, clean and un molested. The car was a SR20DE and auto but I wasn't too fussed as I had my SR20DET engine and manual setup out of the other car. A deal was made and I picked it up the next day.

I drove it home with a annoyingly loud fart cannon of an exhaust complete with edaboc stickers on the rear window. I got home and took off the stickers and removed the fart cannon exhaust and swapped it for the factory item the previous owner gave me.

I think the previous owner tried to tuck this exhaust against the subframe. Very weird..

I continued to drive it as is for around 5 weeks while saving money and planning what I was going to do with this new car. I started by contacting Alex from Moonlight Racing and ordered an Origin Lab Stylish Body kit and 20mm front fenders.

I moved the wrecked S14 to the yard to I could start to dis assemble it.

I started with the engine and gearbox

First I drained all the fluids and removed all intercooler piping and radiator. Next was to disconnect all the wiring and hoses connected to the engine etc..

Next it was time to strap the engine up and remove the engine mount bolts, support the gearbox with a jack and remove the gearbox cross member. Then we slowly started to lift the engine and gearbox out checking for anything connected to the engine. Everything was free and out it came

The next day I took off the bell housing bolts to remove gearbox as I was selling it because I'll be upgrading, and to check out the condition of the flywheel and clutch.

This is what the clutch looks like. Pretty toast right? I'll be replacing this with a new item but am un decided on what one at the moment.

Next to come out was the dash, centre console, door trims, centre climate control, steering wheel, quick release, ecu etc.. Everything inside came out so I could swap it all over

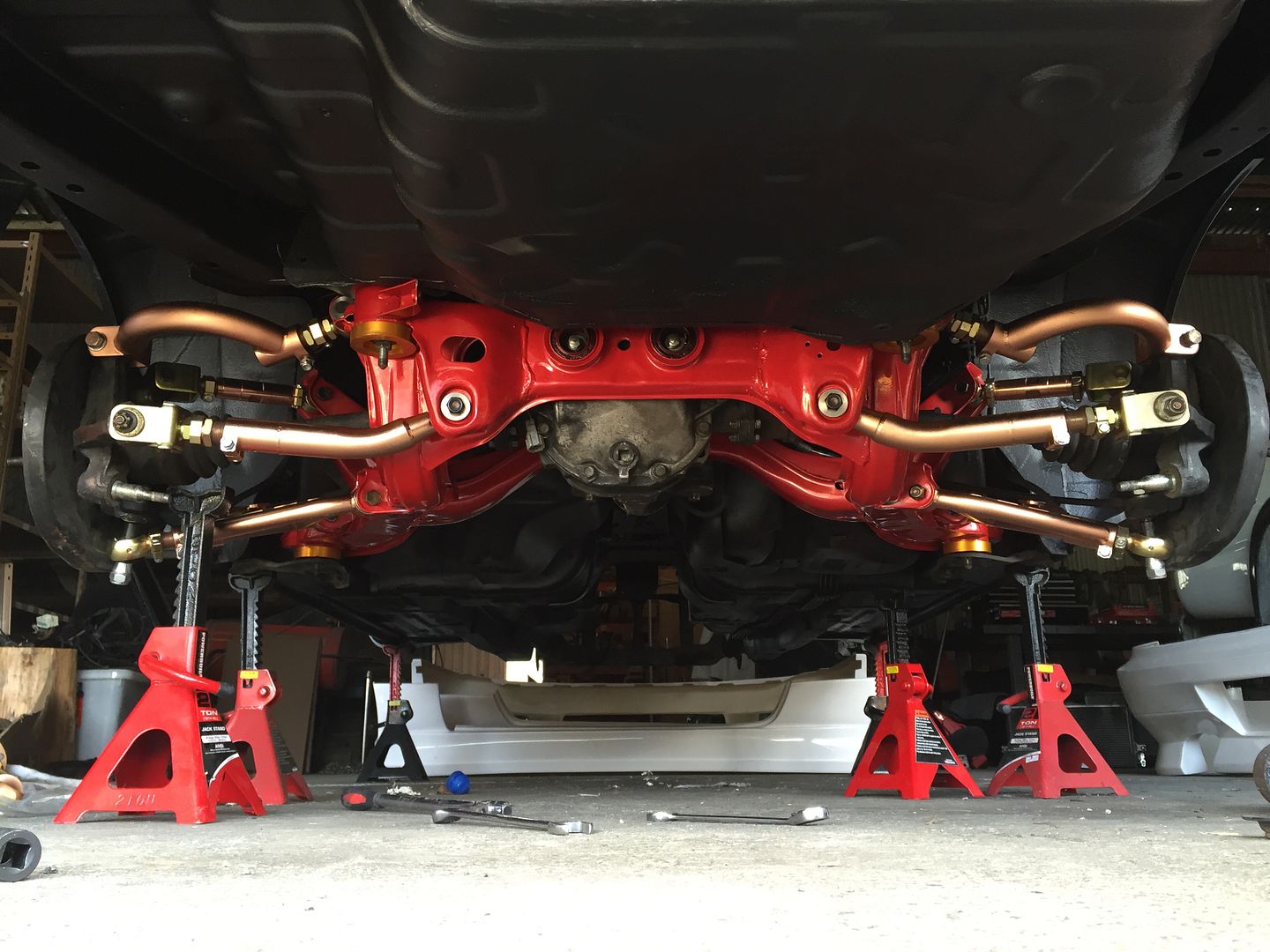

Onto the subframe next, the driveshaft was already removed so it was simply removing calipers and tie them out of the way, undo the lower coilover bolt, remove handbrake cable brackets, support the subframe with the jack and undo the bolts holding the subframe and slowly lowering it down with the jack.

Next was removing the whole front crossmember including brakes/ rotors/ suspension

I scavenged a few more things from it and at this stage it was a stripped shell sitting on stands.

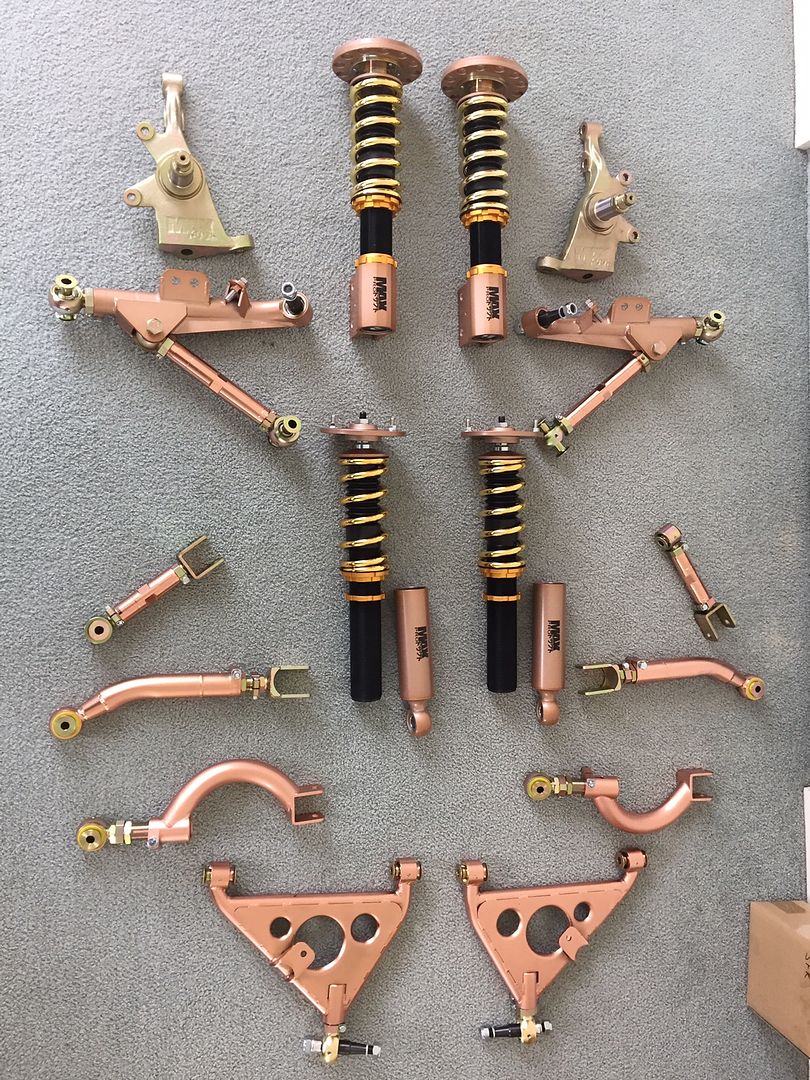

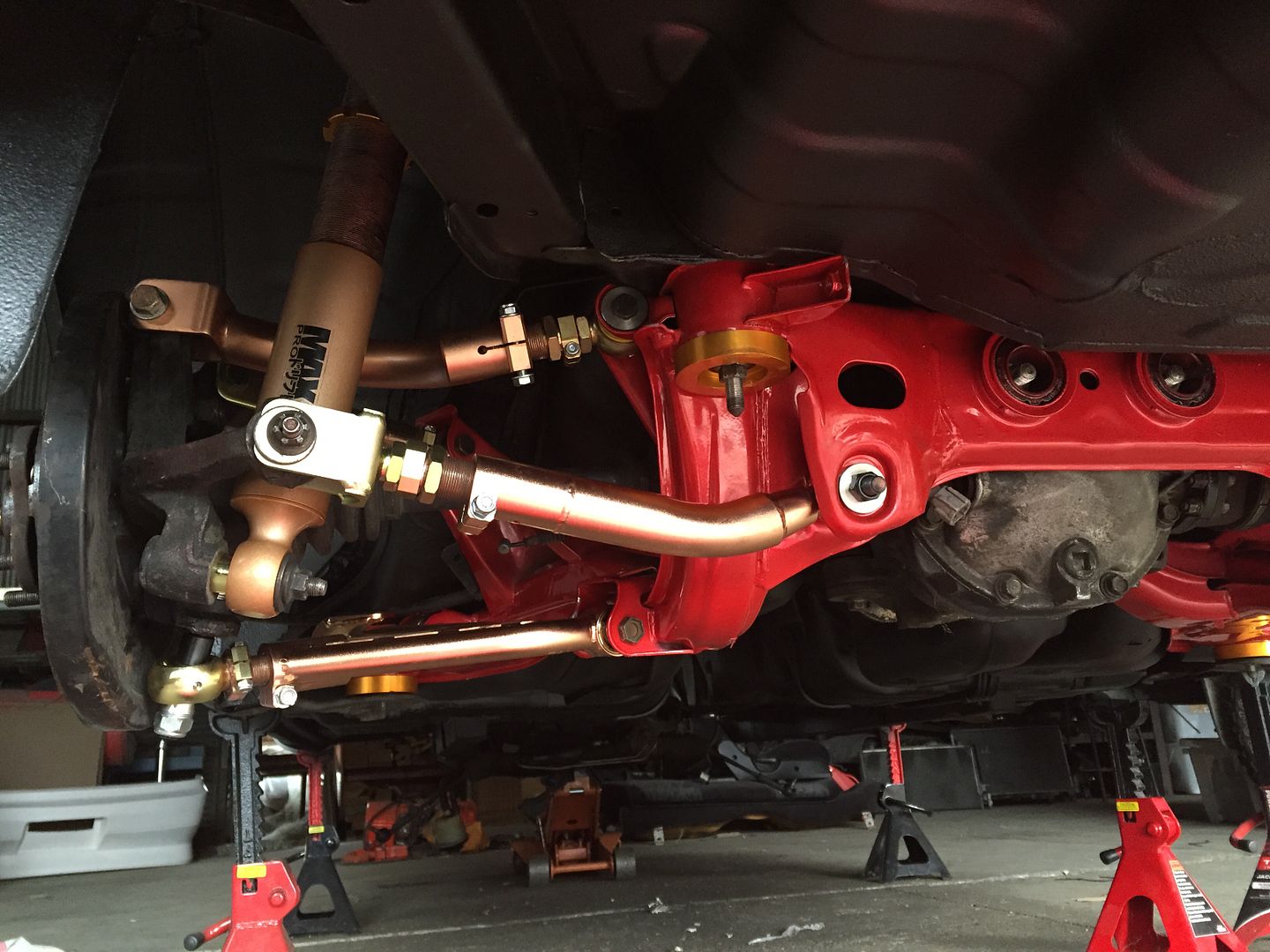

Hopefully all being well, I'll be able to get the PBM front knuckle and LCA setup like you in the near future, just the quality of the PBM gear speaks for itself.

Hopefully all being well, I'll be able to get the PBM front knuckle and LCA setup like you in the near future, just the quality of the PBM gear speaks for itself. Yeah bling bling shiny haha, Go for it! You wont regret it

Yeah bling bling shiny haha, Go for it! You wont regret it

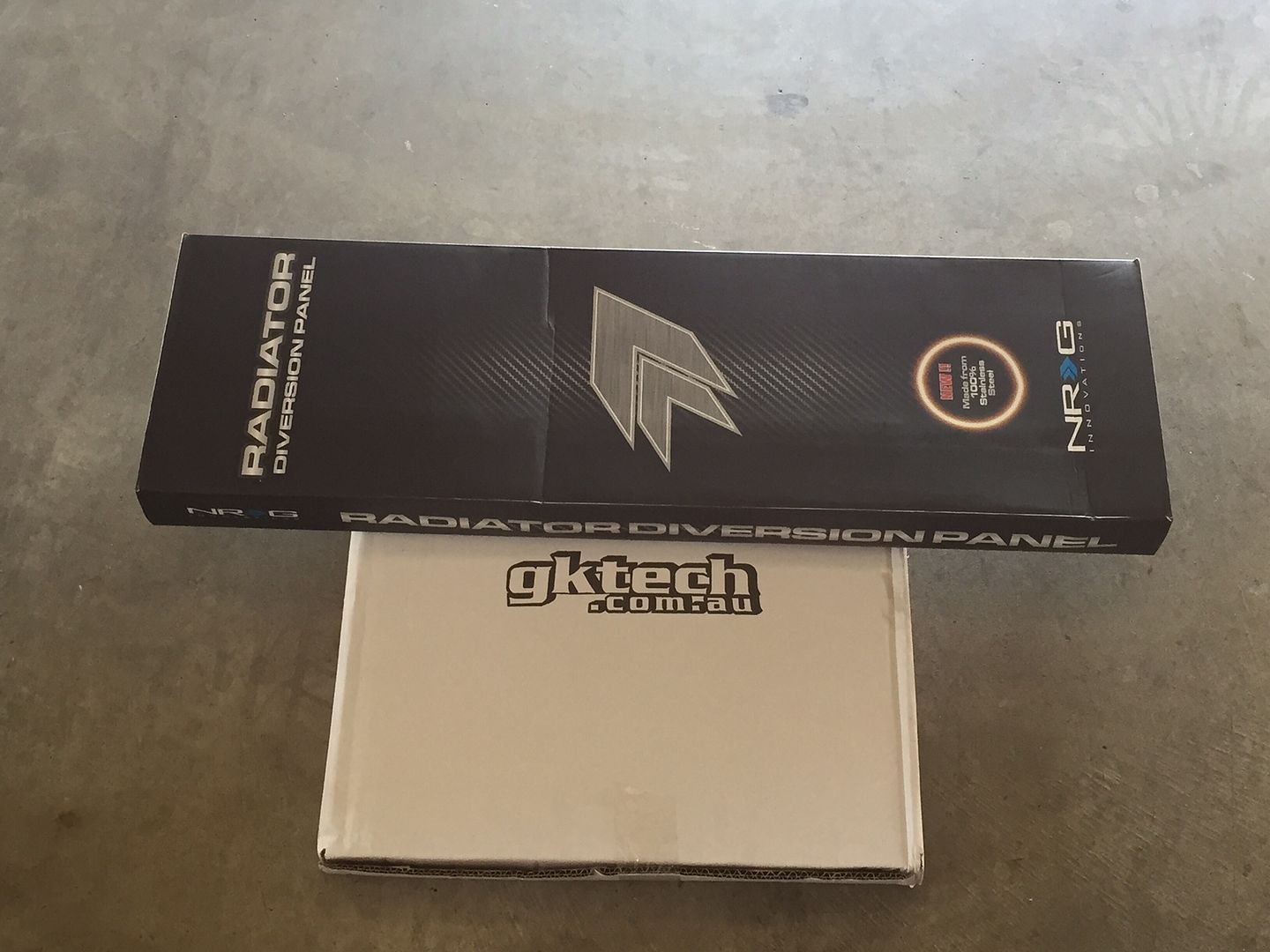

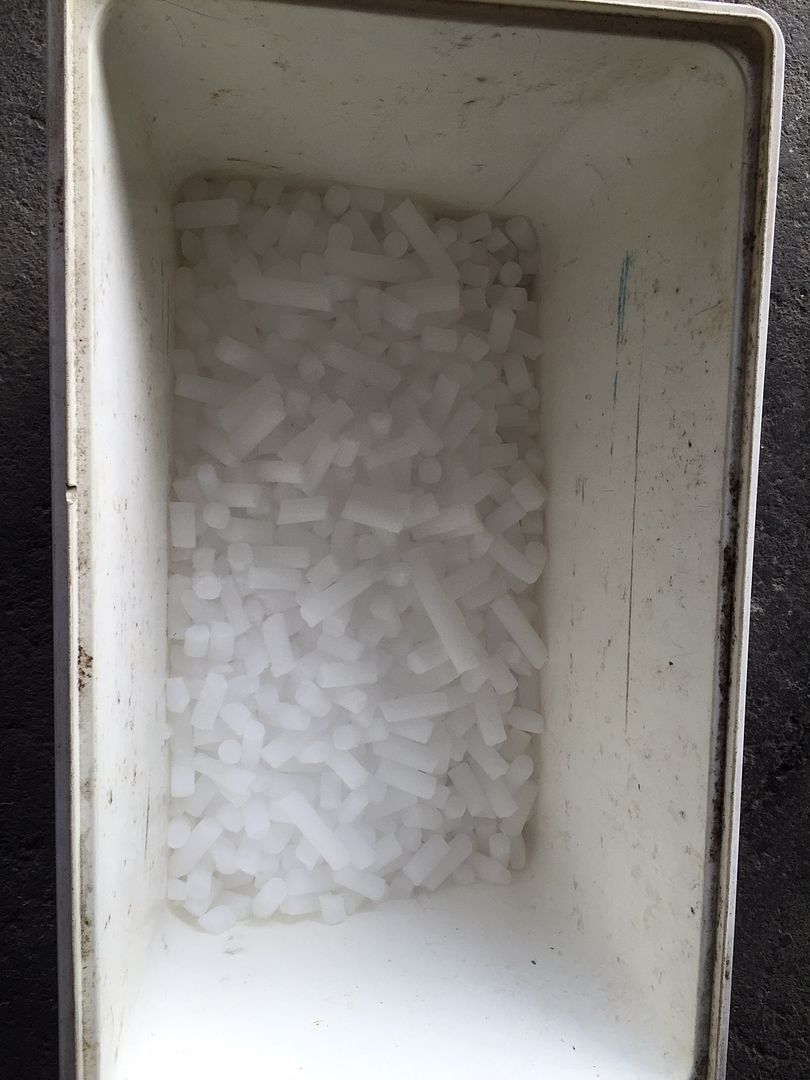

When the car gets back I will update you all. Here's a little teaser

When the car gets back I will update you all. Here's a little teaser

lol

lol