Sidewayzz

Member

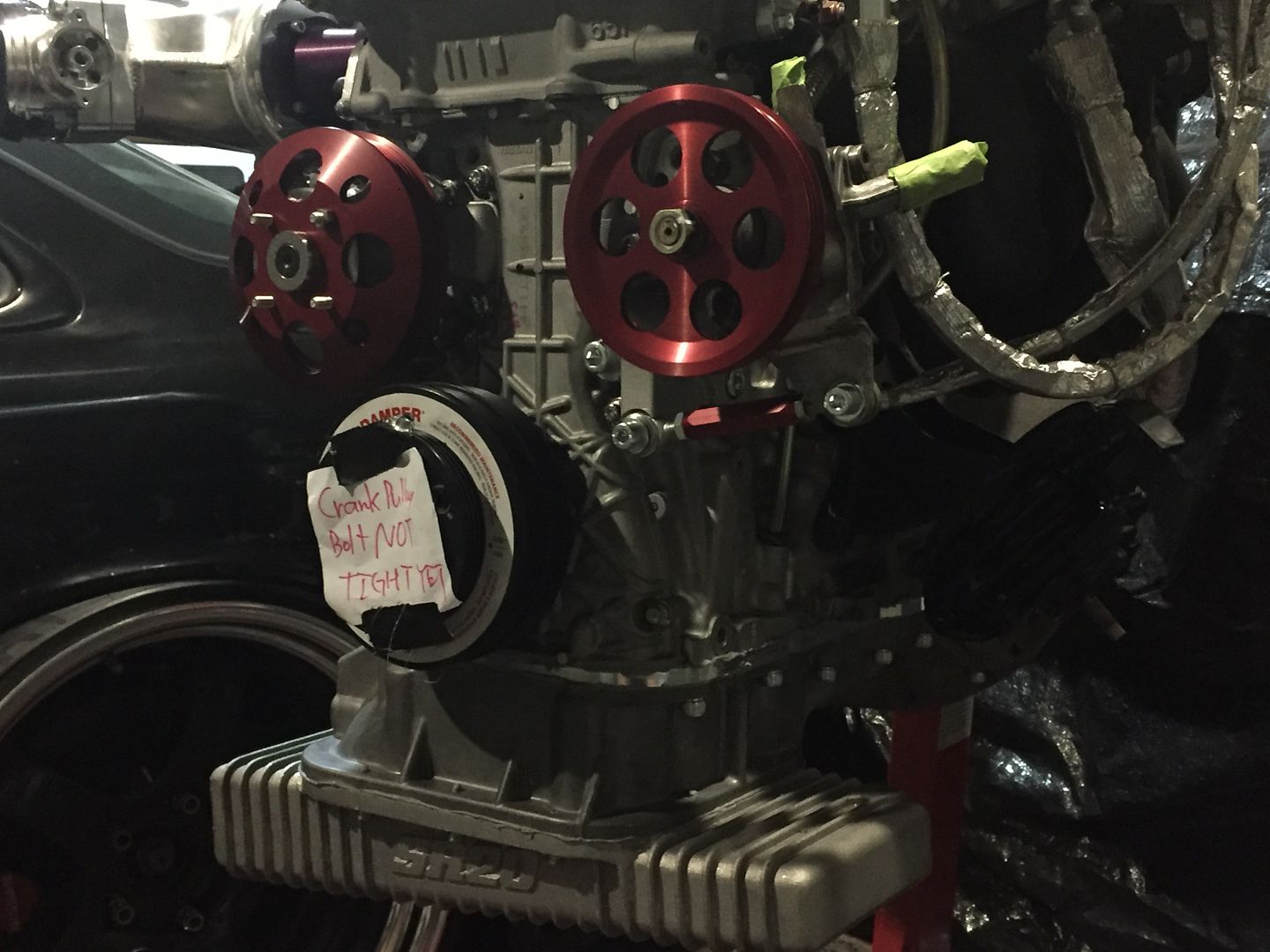

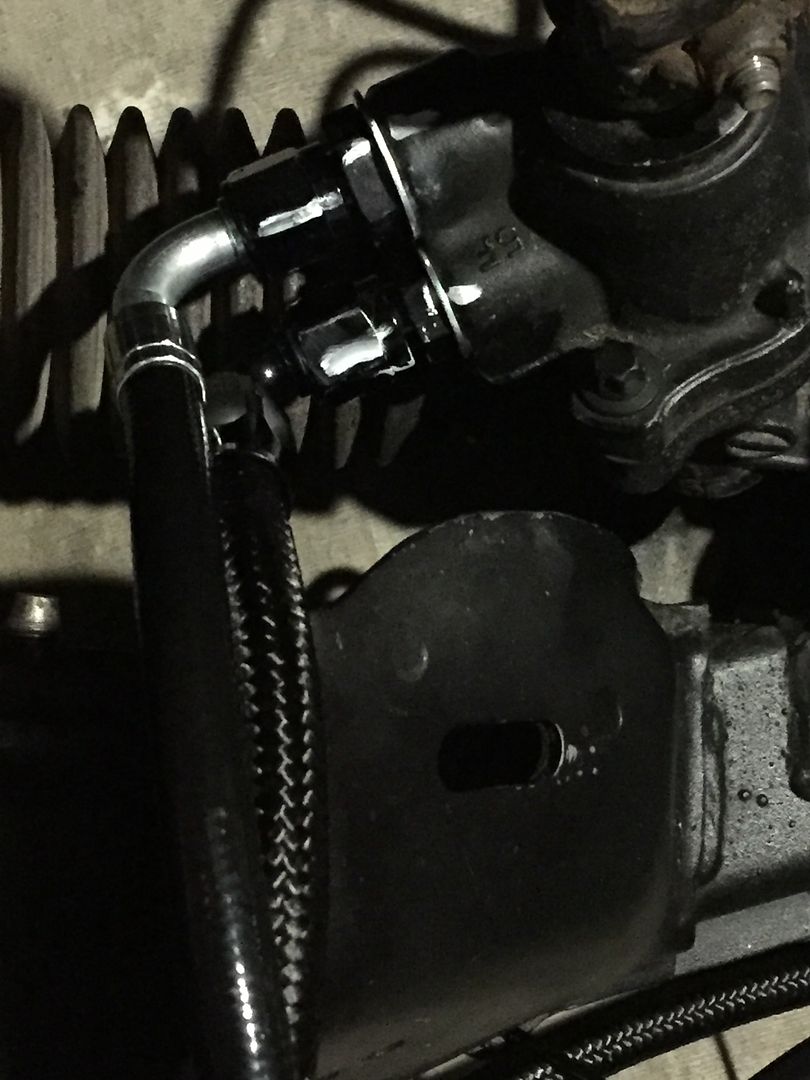

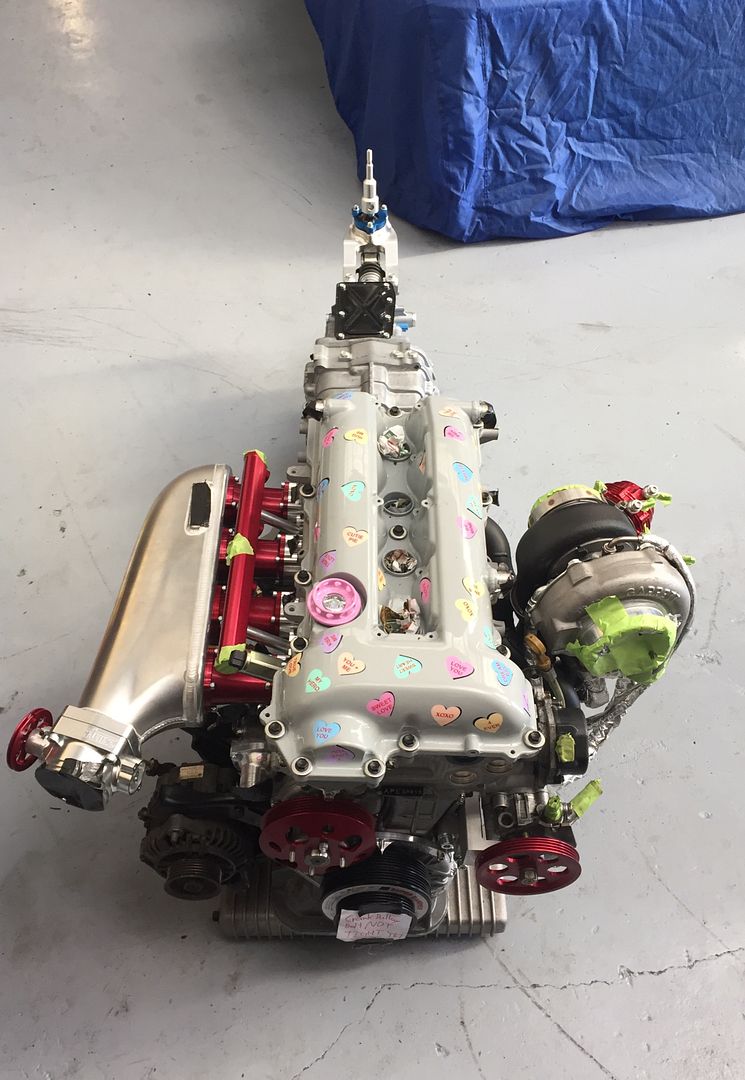

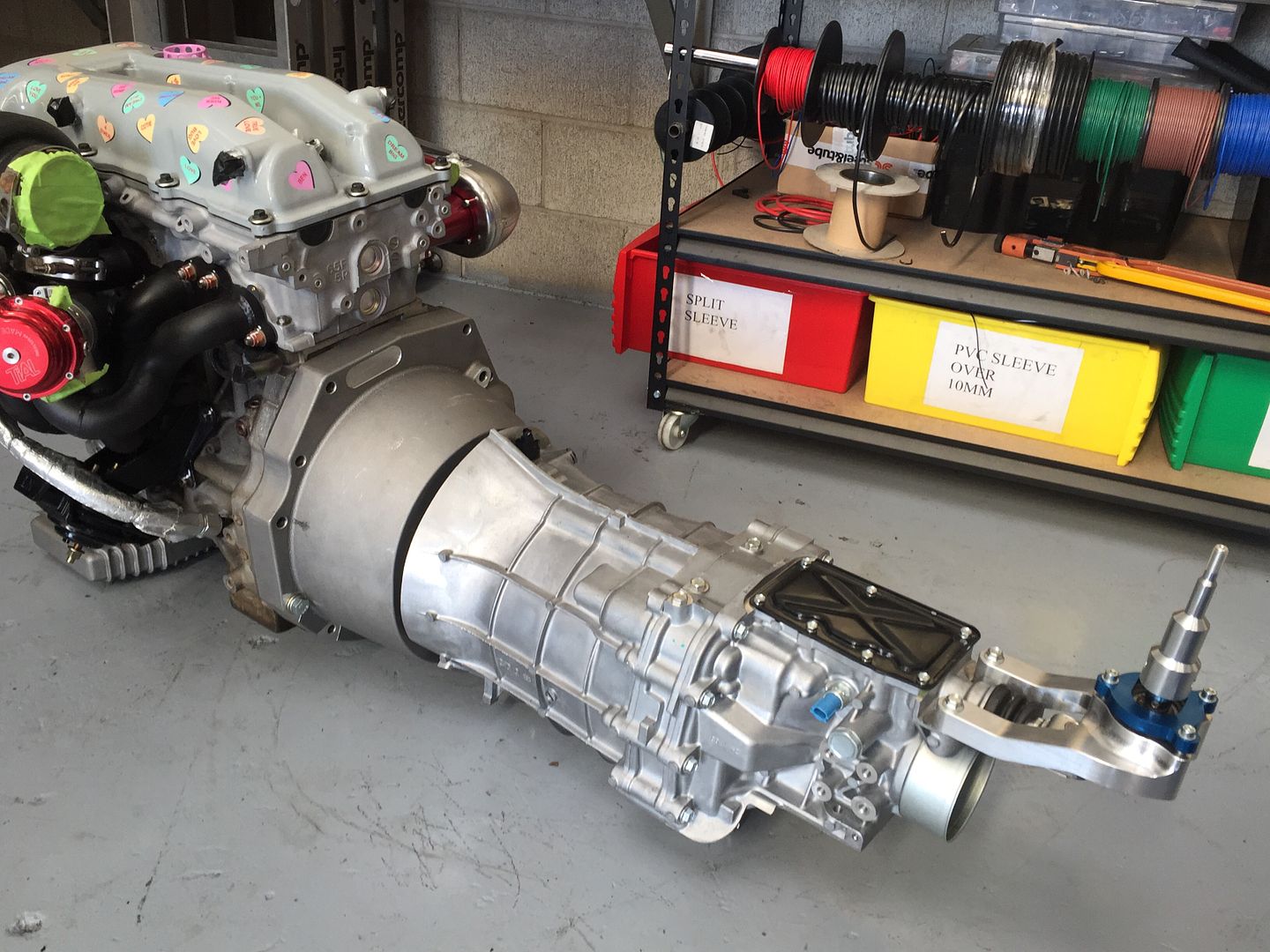

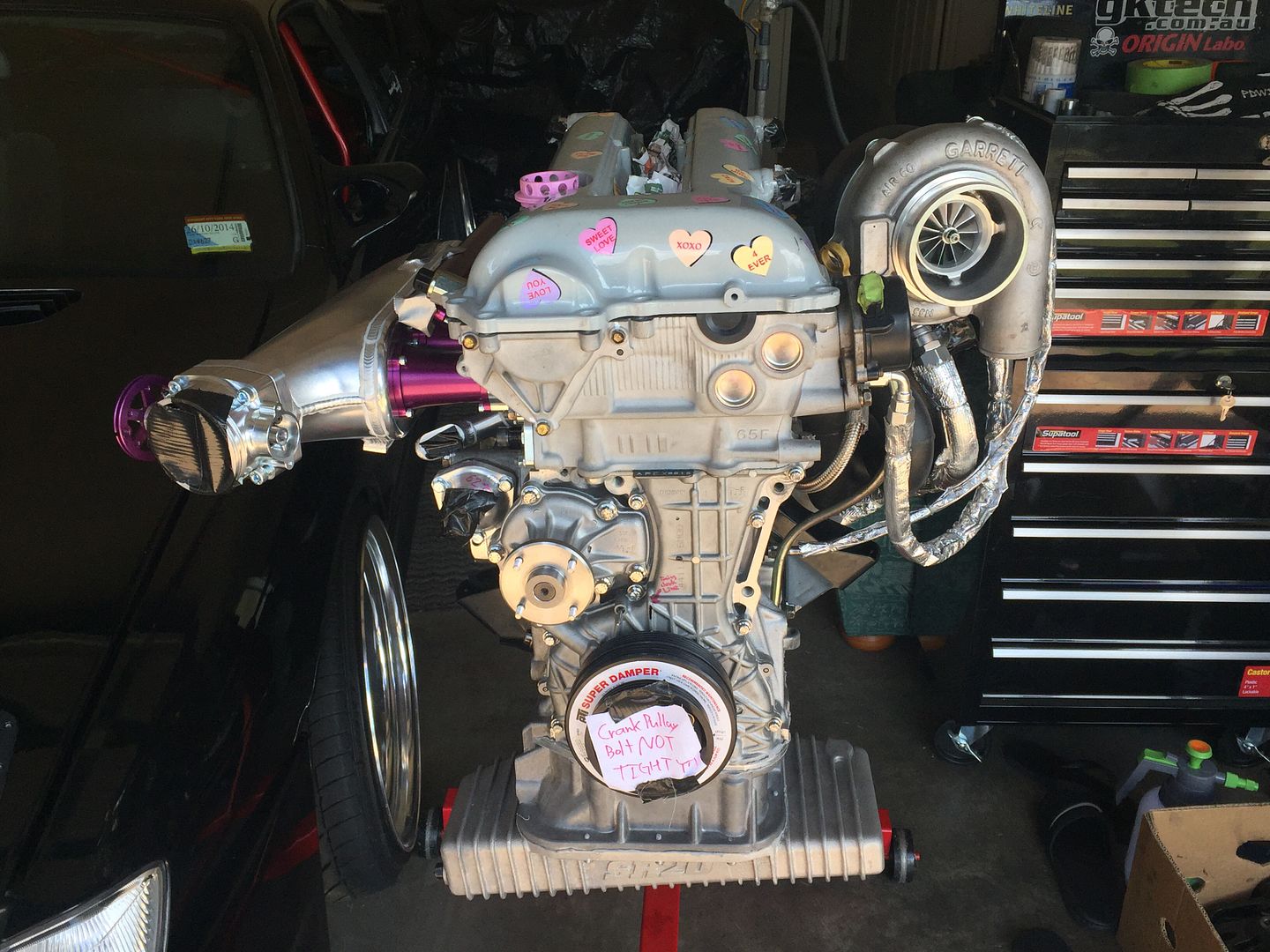

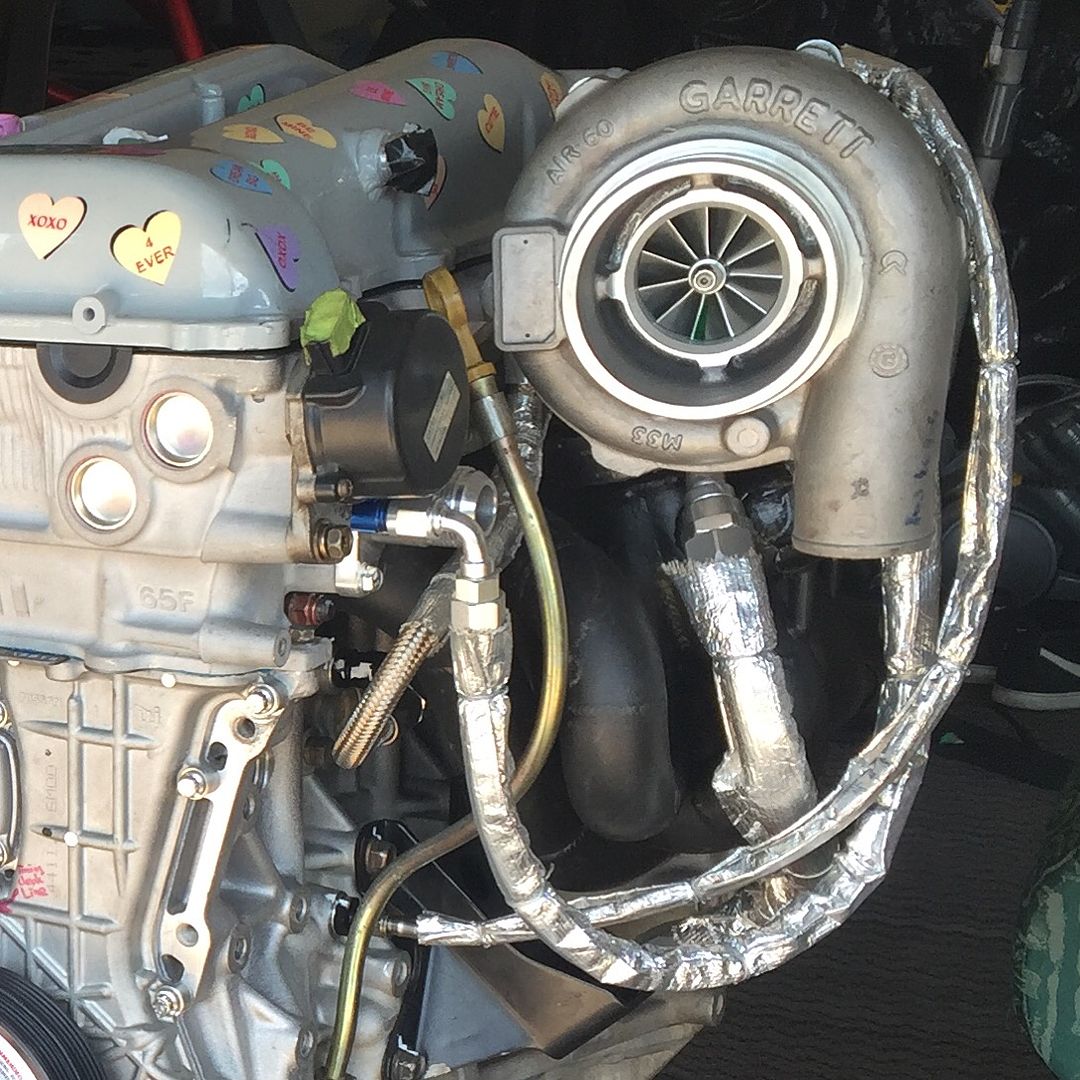

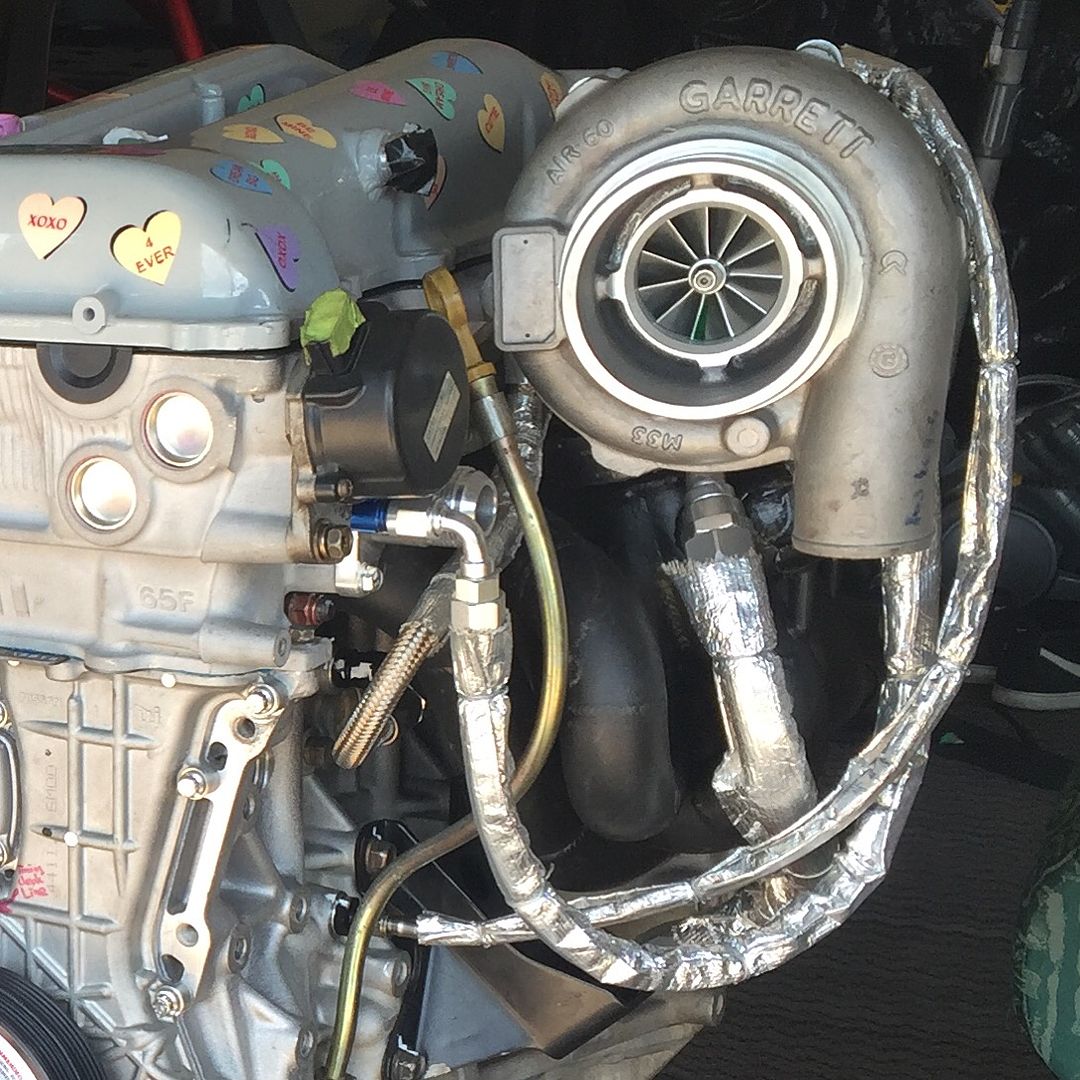

Turbo side all bolted on and oil/ water lines routed.

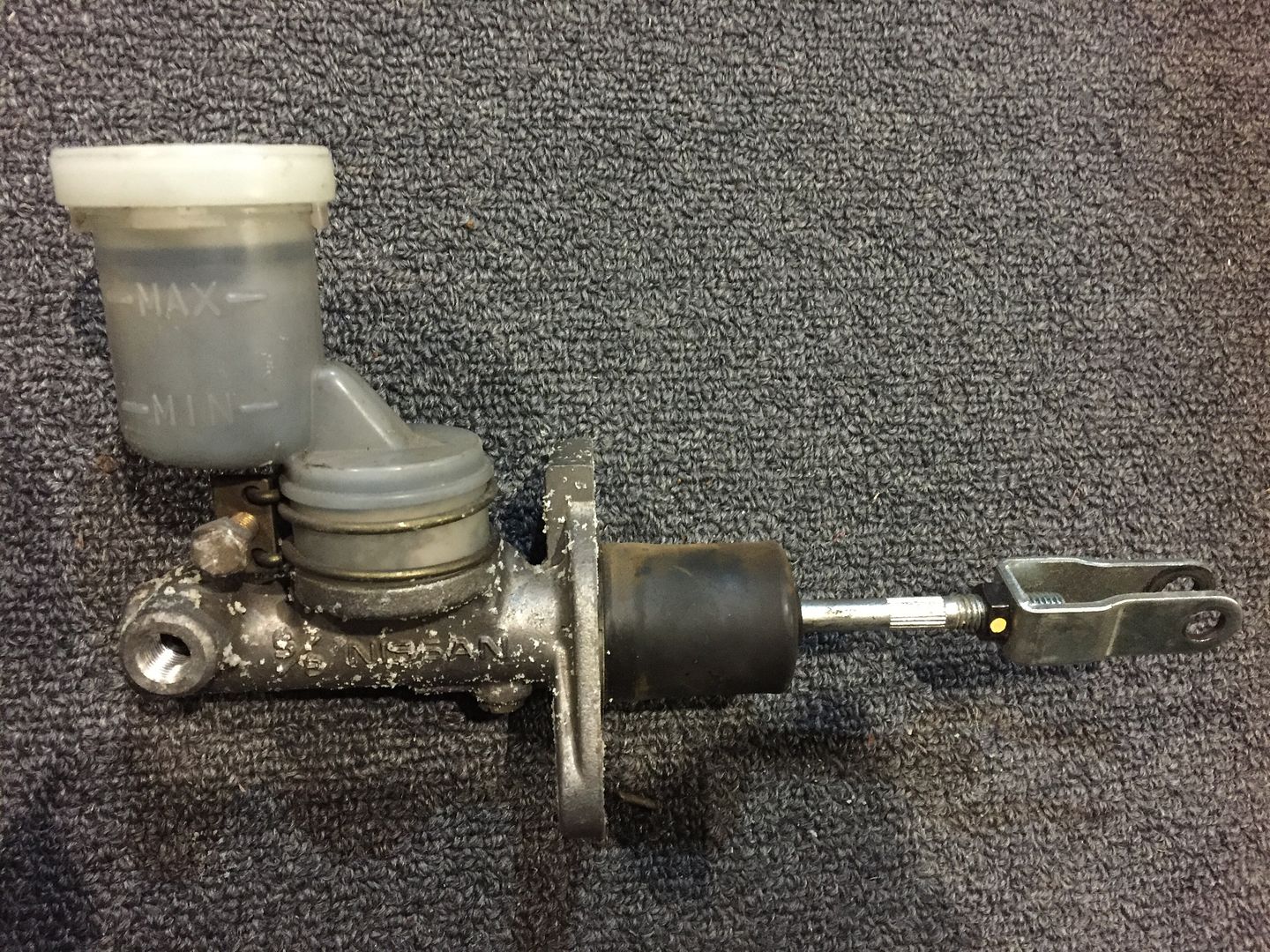

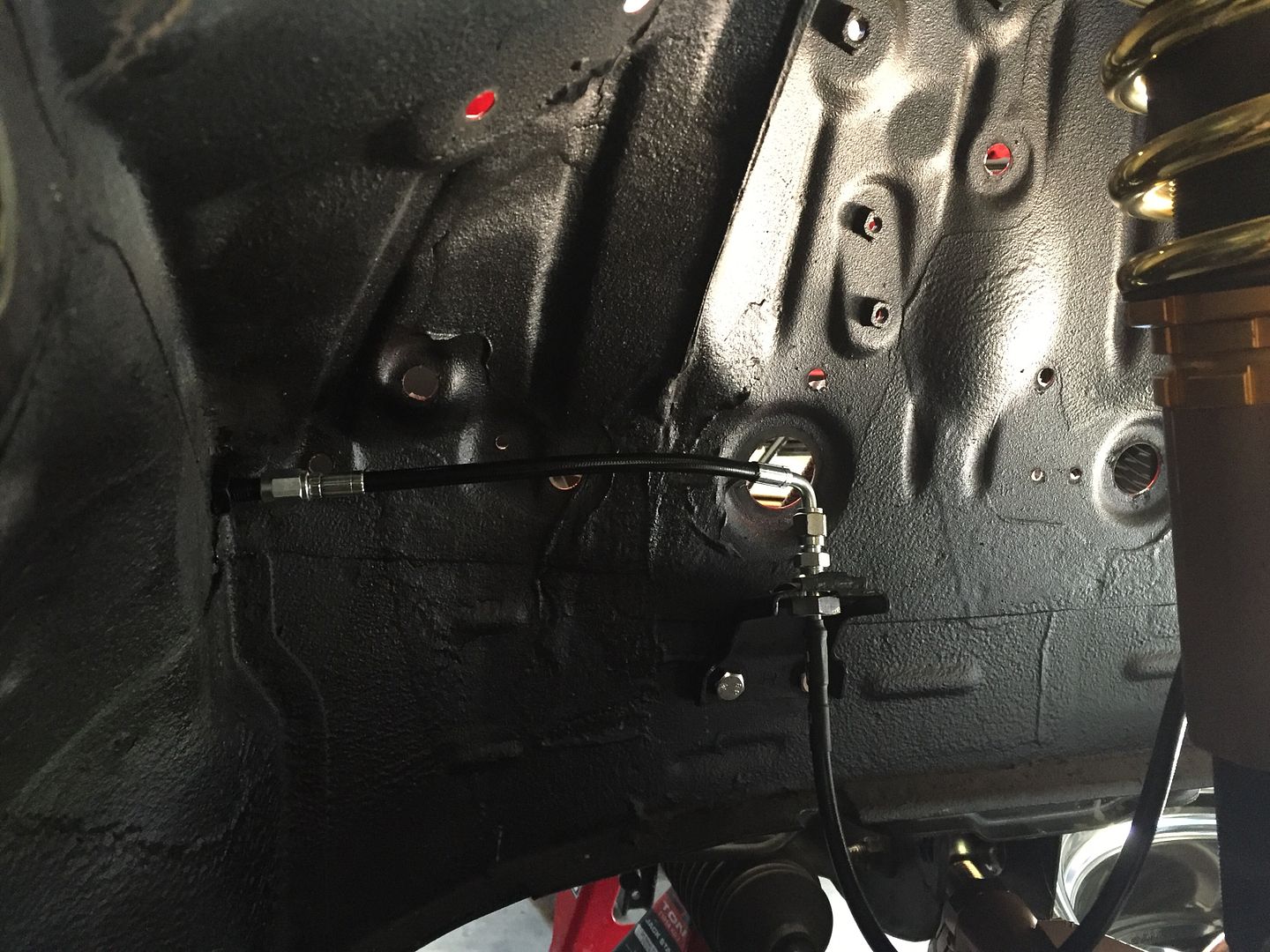

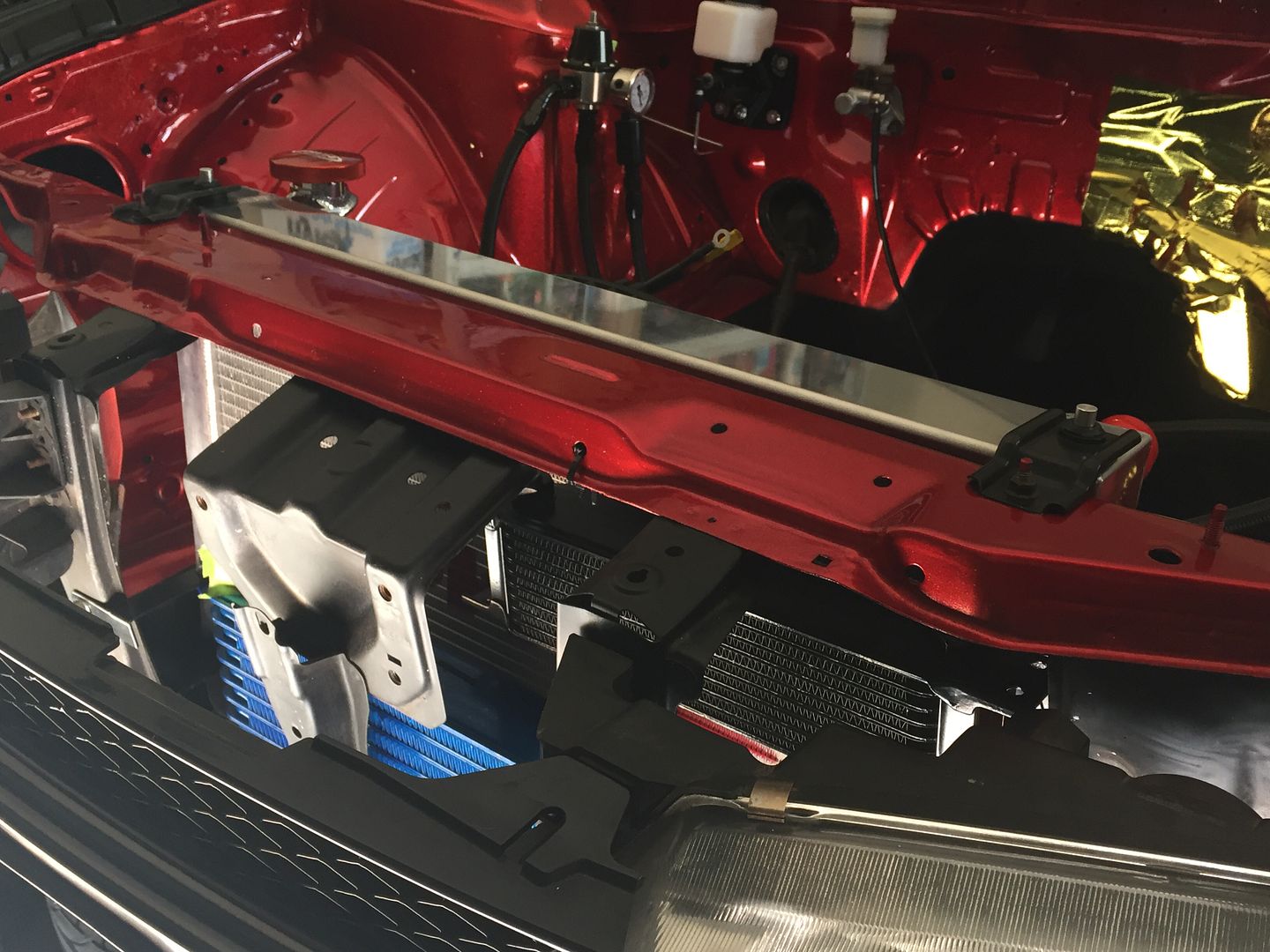

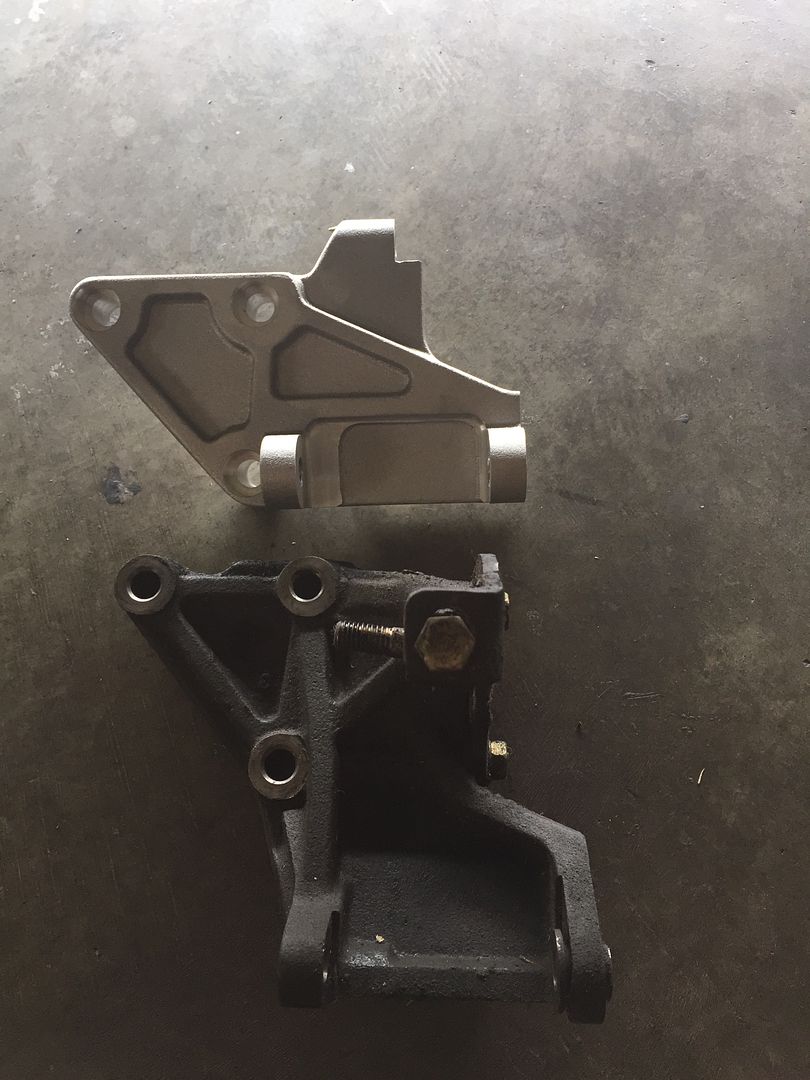

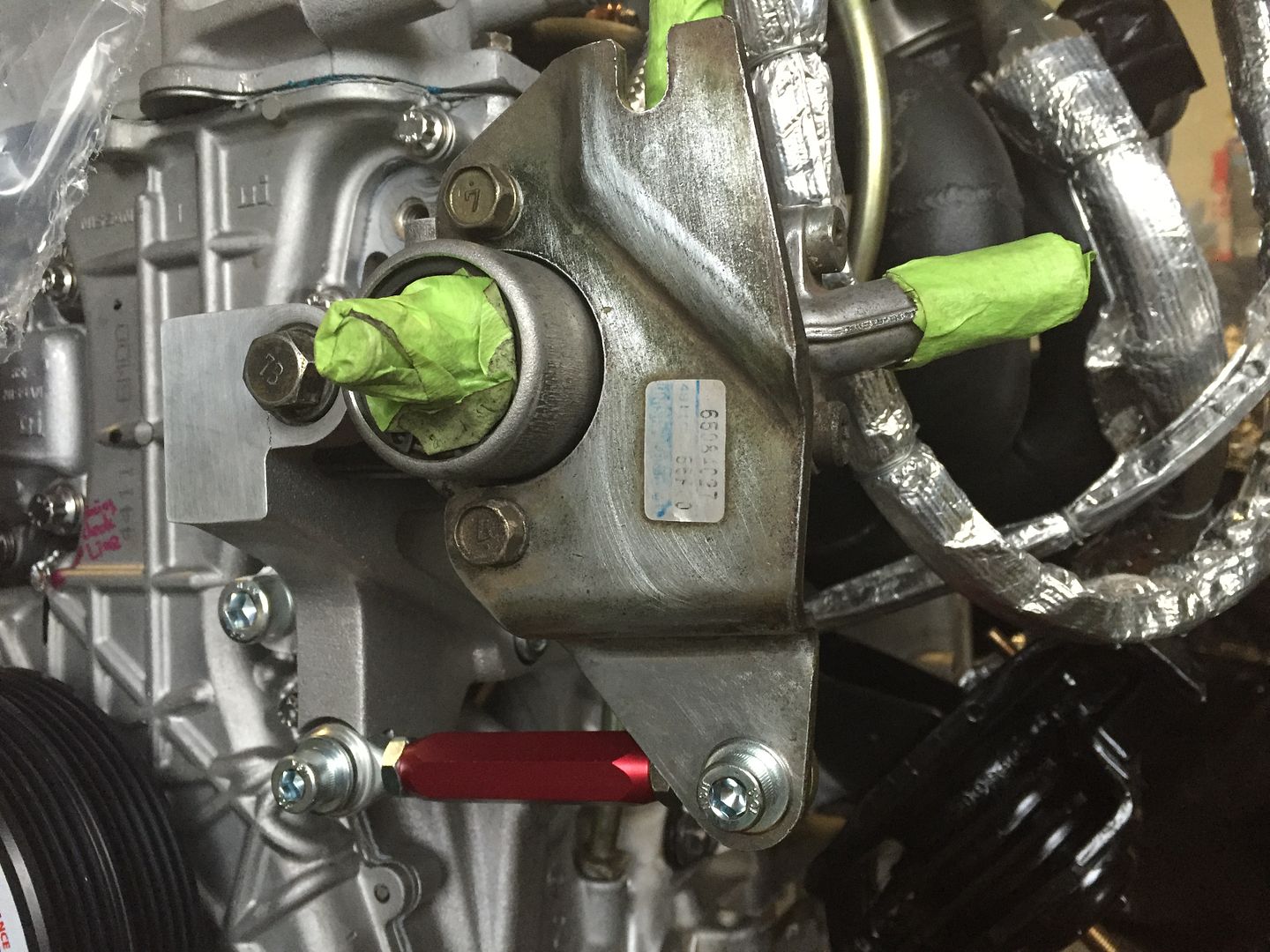

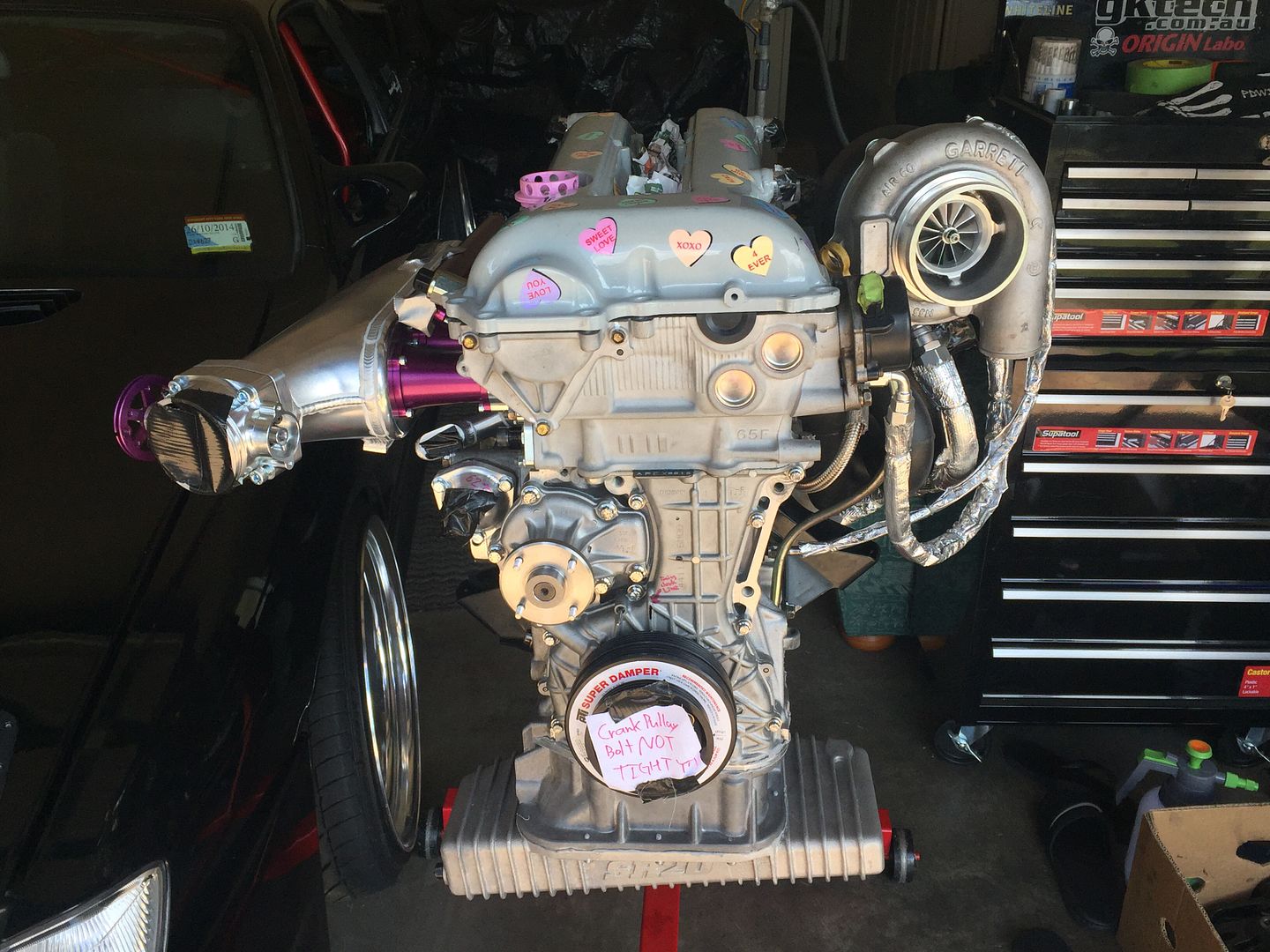

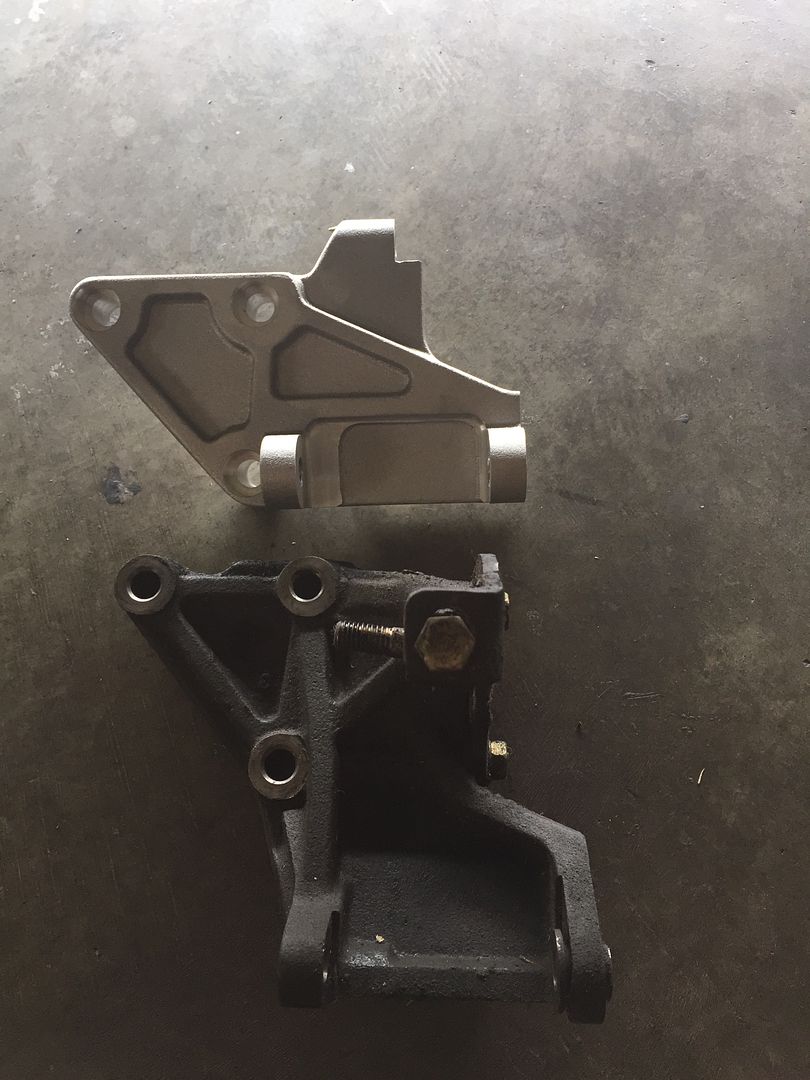

Since i wasn't going to run air conditioning anymore I decided to get a low mount power steering bracket made by Naprec.

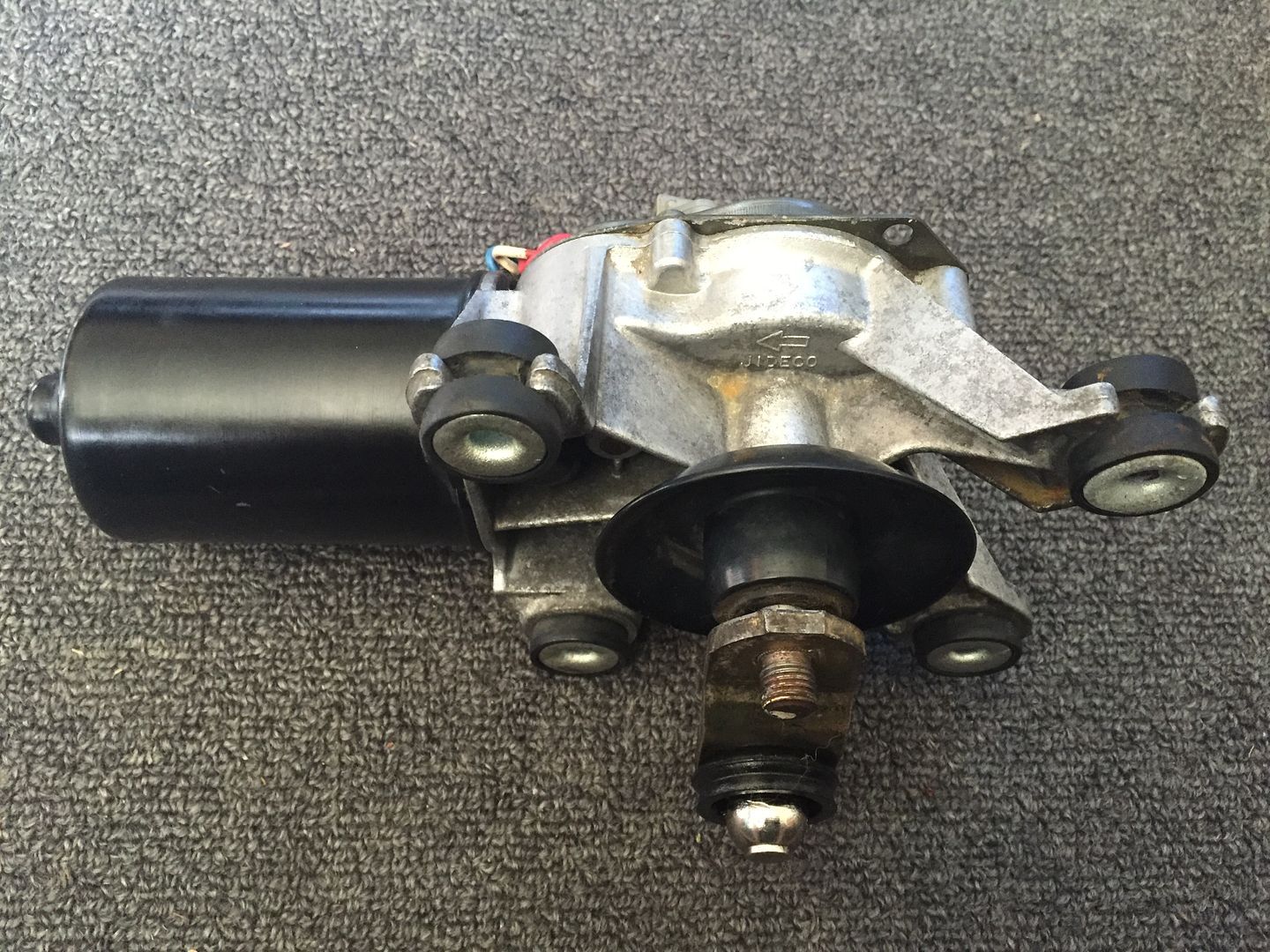

Naprec vs Factory.

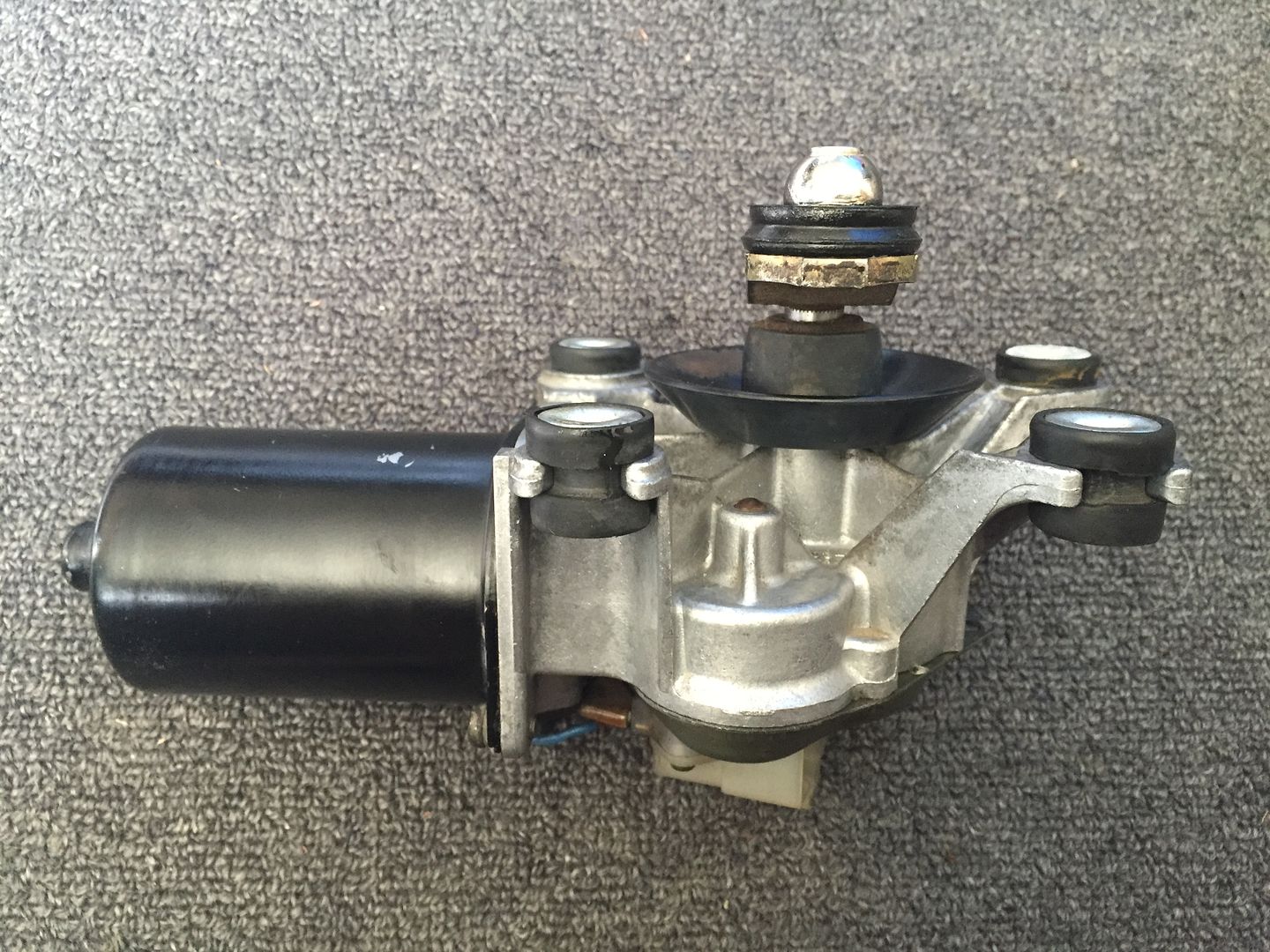

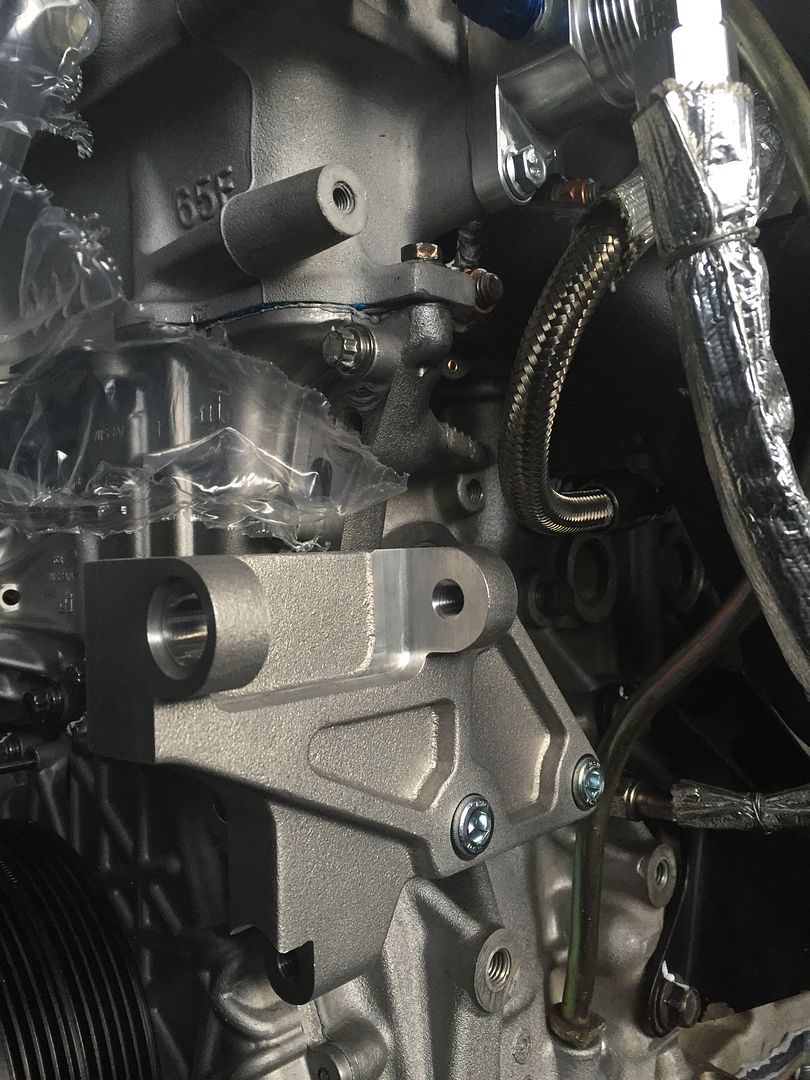

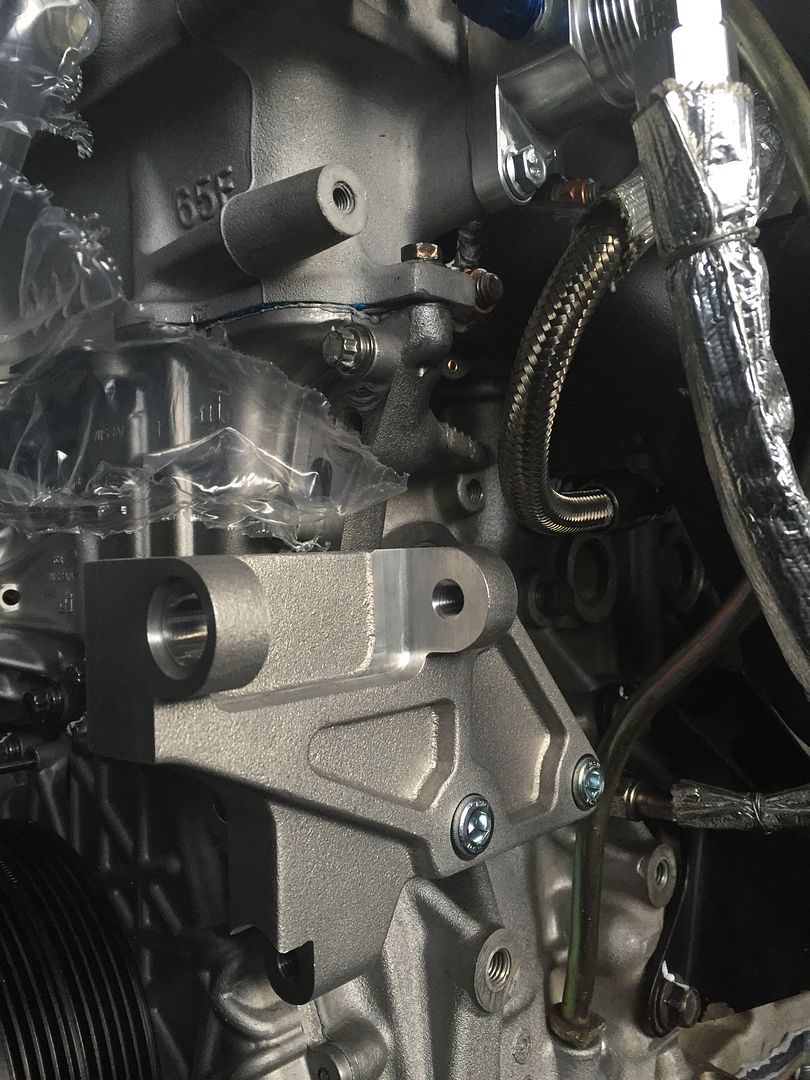

Installed.

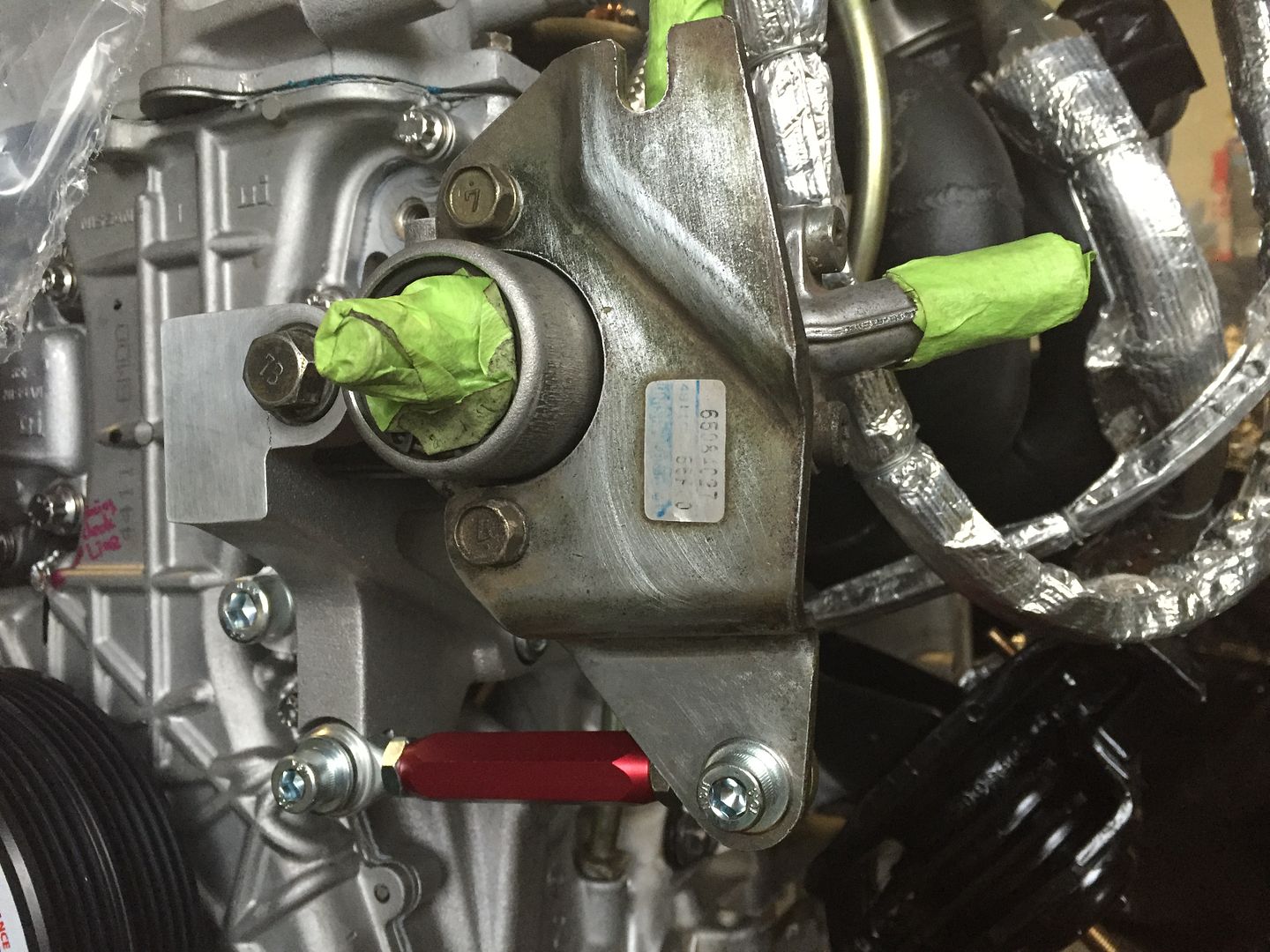

Couldn't bring myself to putting on a dirty pump so gave it a quick clean.

All done. This one doesn't sit as low as some designs but it is nice and sold and not flimsy like other designs i have heard about.

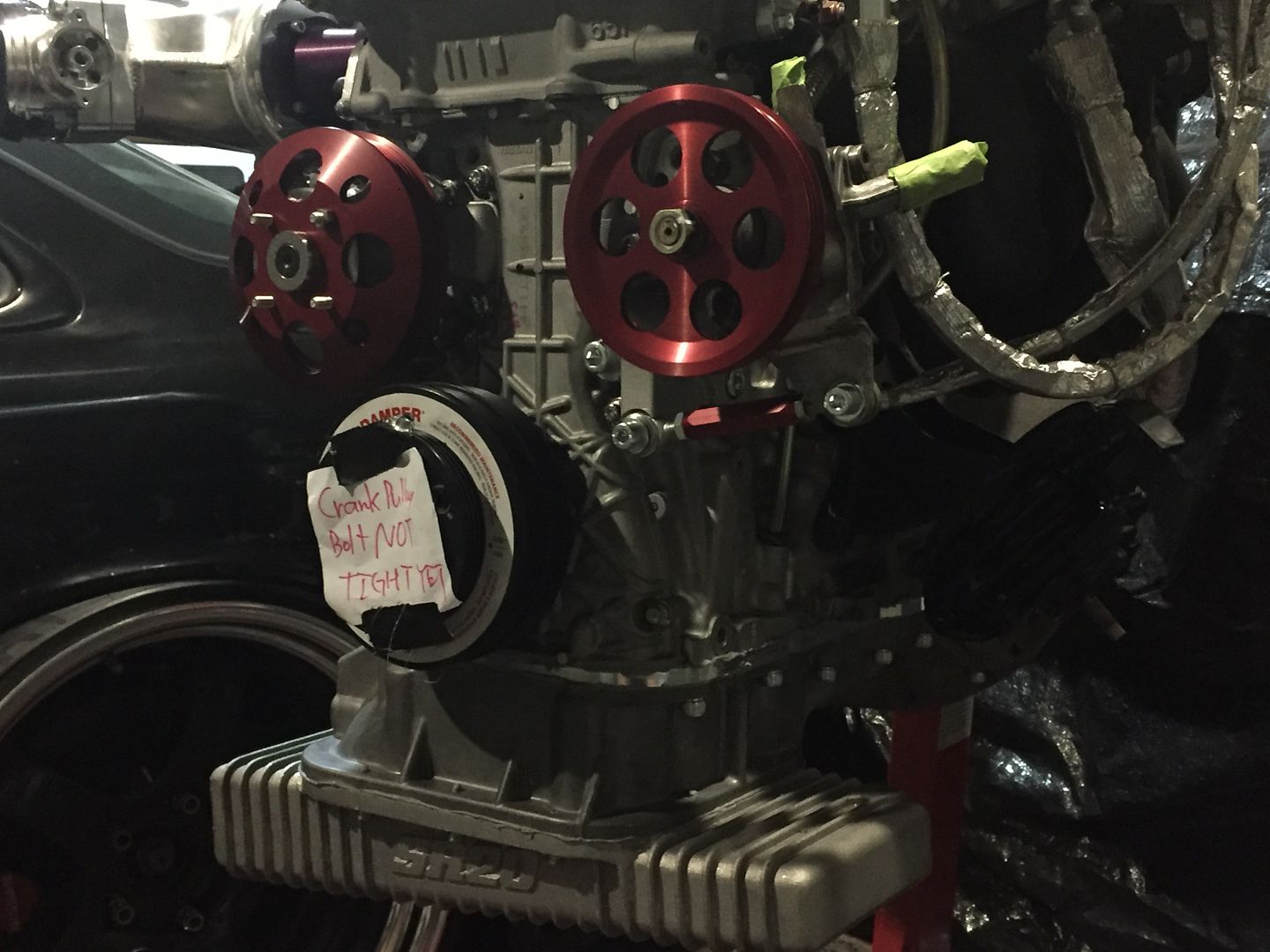

Put on some large Naprec power steering and water pump pulleys.

Since i wasn't going to run air conditioning anymore I decided to get a low mount power steering bracket made by Naprec.

Naprec vs Factory.

Installed.

Couldn't bring myself to putting on a dirty pump so gave it a quick clean.

All done. This one doesn't sit as low as some designs but it is nice and sold and not flimsy like other designs i have heard about.

Put on some large Naprec power steering and water pump pulleys.